Cycloolefin copolymer and preparation method thereof

A technology of cyclic olefin copolymers and polymerization reaction products, which is applied in the field of copolymers, can solve the problems of poor heat resistance, poor mechanical properties, and poor elongation at break of cyclic olefin copolymers, and achieve good transparency, Good heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of cycloolefin copolymer described in above-mentioned technical scheme, comprises the following steps:

[0038] 1), under the action of a catalyst, a compound having a structure shown in formula II and a compound having a structure shown in formula III are polymerized in a solvent to obtain a polymerized reaction product;

[0039] 2), hydrogenating the polymerization reaction product and a hydrogen source to obtain a cycloolefin copolymer;

[0040]

[0041] In the present invention, preferably, the compound having the structure shown in formula II, the compound having the structure shown in formula III and a solvent are mixed, and a catalyst is added to the obtained mixture for polymerization reaction to obtain a polymerization reaction product. In the present invention, the compound having the structure represented by formula II, the compound having the structure represented by formula III and the solvent a...

Embodiment 1

[0100] Add 800 mL of norbornadiene, 230 grams of anthracene and 1 gram of 2,6-di-tert-butyl-p-cresol in sequence to a 2-liter stainless steel autoclave, and repeatedly vacuumize the autoclave 3 times Nitrogen filling operation: the autoclave was heated to 180° C., and the contents in the autoclave were reacted for 30 hours under stirring conditions.

[0101] After the reaction, the obtained reaction product was cooled to 25° C., left to stand for 12 hours and then filtered. The obtained filtered product was washed twice with n-hexane to obtain 260 g of the product. The yield of the product prepared by the method provided in Example 1 of the present invention was 75%.

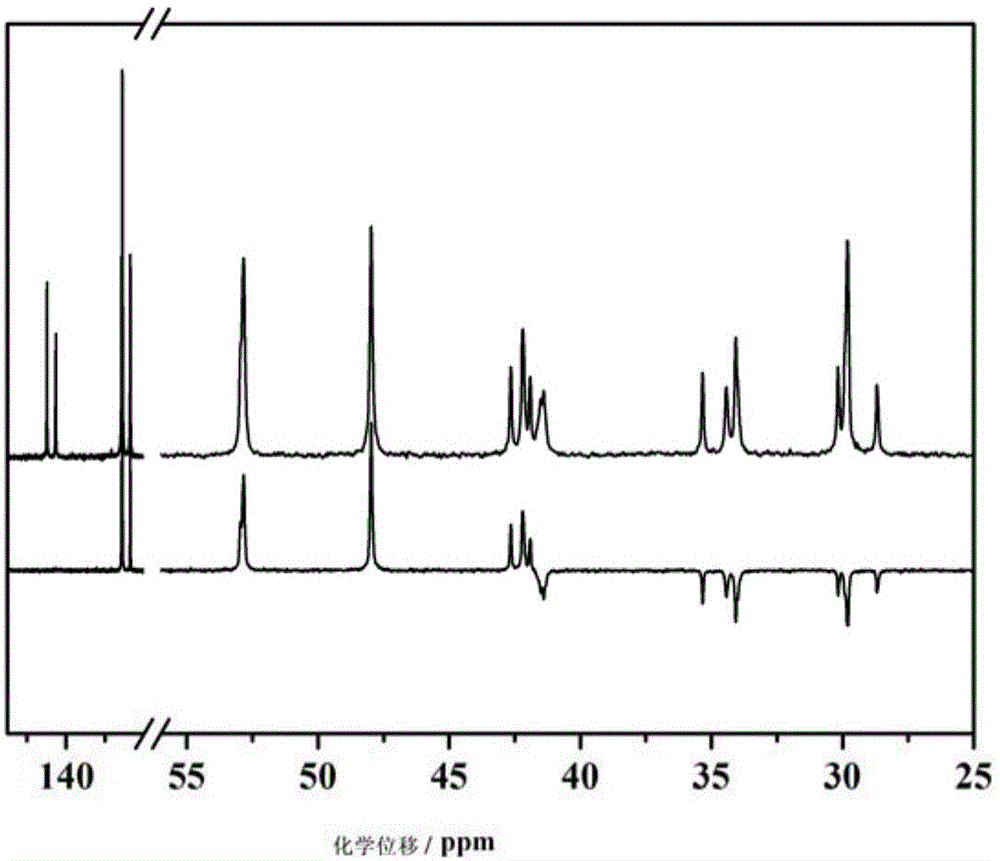

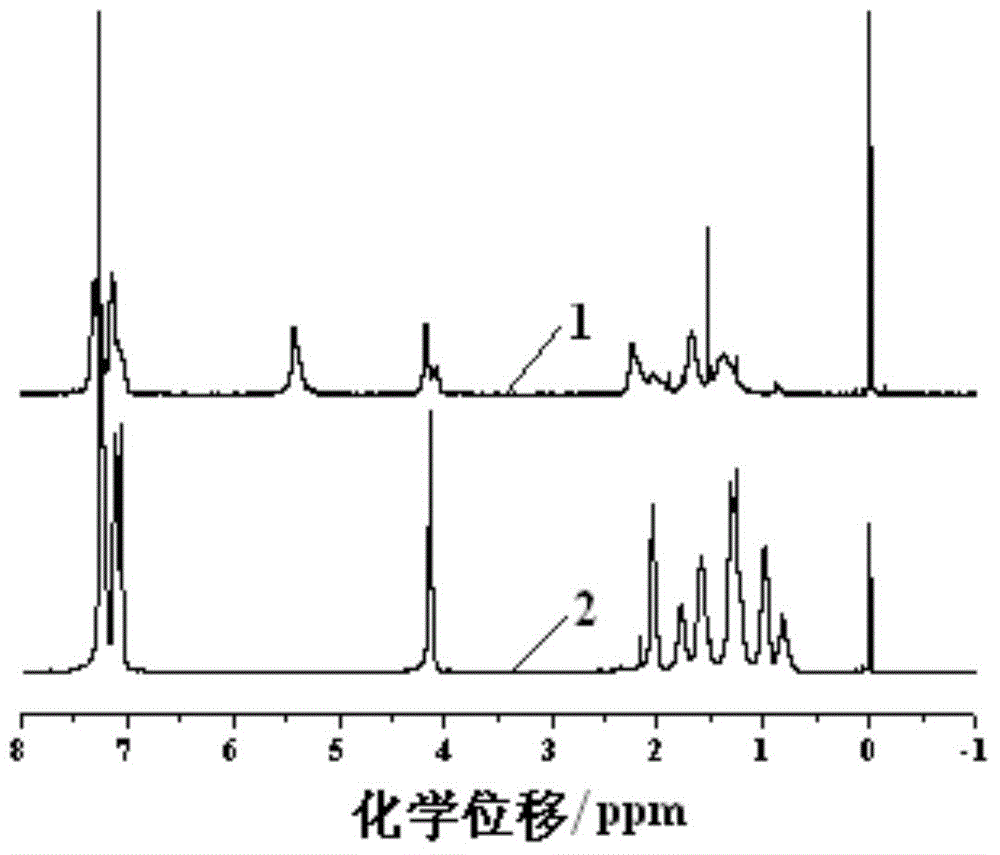

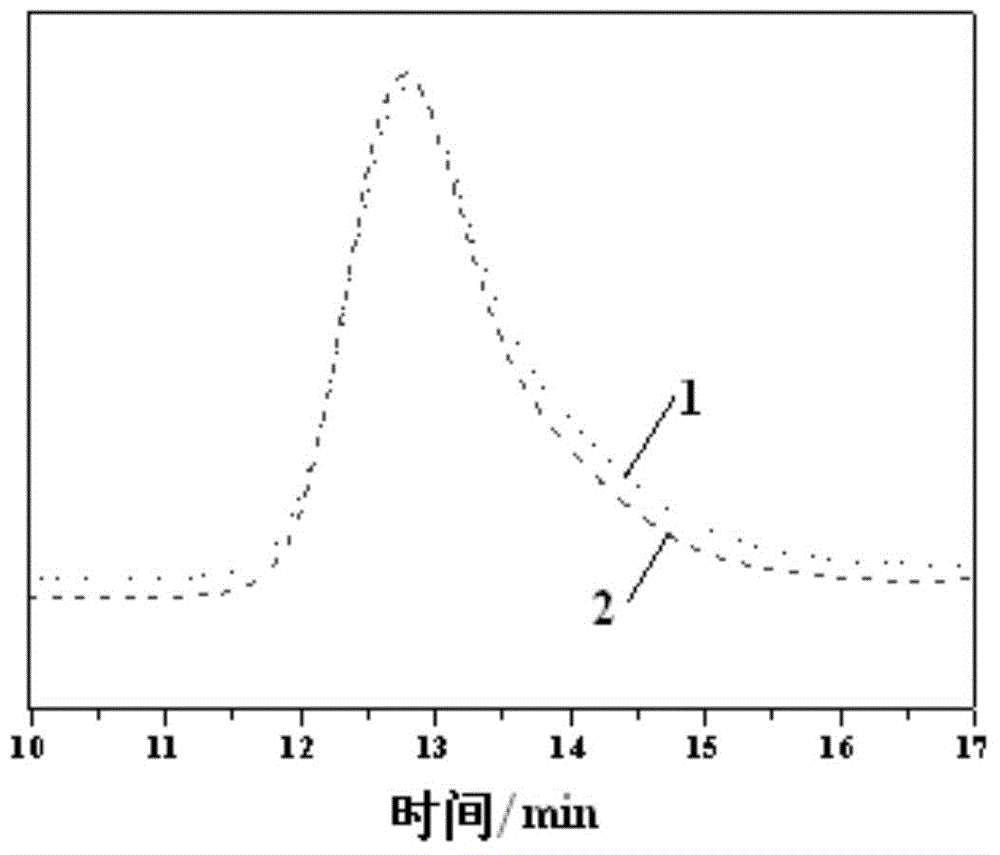

[0102] The product obtained above was subjected to proton nuclear magnetic resonance spectrum detection and carbon nuclear magnetic resonance spectrum detection, and the detection result was that the product obtained in Example 1 of the present invention was a compound having the structure shown in formula II. ...

Embodiment 2

[0104]Add 4.96 grams of benzaldehyde-p-toluenesulfonylhydrazone, 1.75 grams of sodium methoxide and 40 mL of triethylene glycol in a 100 mL single-necked bottle, and place the single-necked bottle in a water bath at 60 ° C for 1 hours of synthesis.

[0105] After the synthesis reaction is completed, the methanol in the obtained synthesis reaction solution is extracted by a water pump to obtain a synthesis reaction product; the synthesis reaction product is extracted with n-pentane in ice water and then extracted with a saturated NaCl aqueous solution, and the The obtained extracted product was spin-dried to obtain phenyldiazomethane; the yield of said phenyldiazomethane was 50%.

[0106] Add 4.0 grams of dichlorotris(triphenylphosphine) ruthenium to a 250mL branch bottle, feed nitrogen to replace the air in the branch bottle, inject 40mL into the branch bottle and freeze it three times with liquid nitrogen - melted dichloromethane; place the check flask in a cold bath at -78°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com