Processing technology of UV-curing fluorine-containing wear-resistant hydrophobic coating

A hydrophobic coating and processing technology, applied in the direction of coating, can solve the problems of electrophoretic layer corrosion, affecting the appearance and durability of aluminum materials, and achieve the effect of improving waterproof performance, stable structure and improving hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

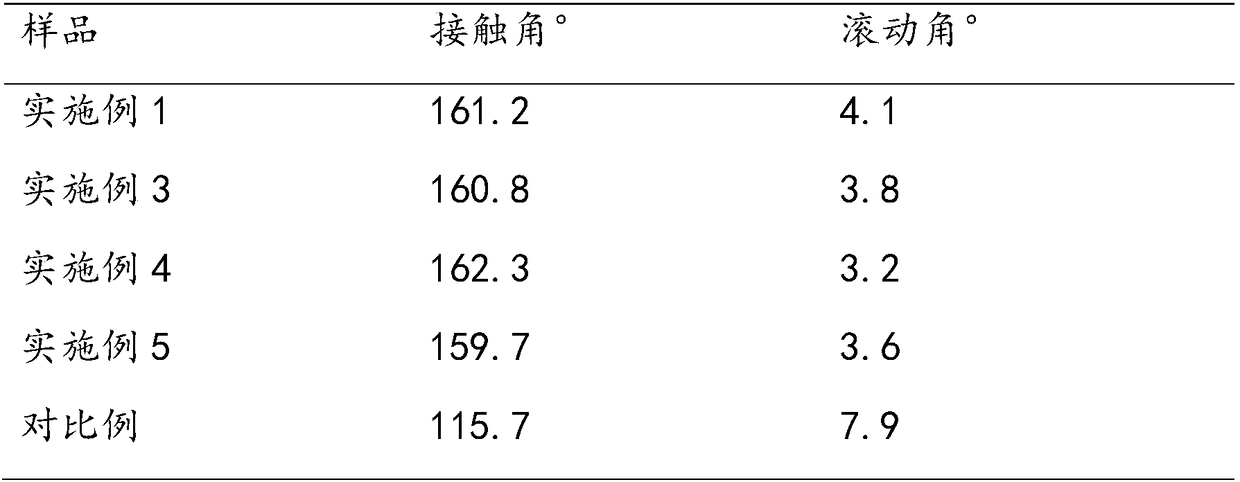

Examples

preparation example Construction

[0057] c, preparation of bottom hydrophobic coating emulsion:

[0058] 1) Dispersing the hydrophobic nano-SiO2 / TiO2 particles prepared in step a into ethyl acetate, and ultrasonically dispersing them for 40-60min to obtain a nano-SiO2 / TiO2 suspension with a dispersion concentration lower than 0.05g / mL;

[0059] 2) slowly adding the nano-SiO2 / TiO2 suspension to the silicone fluorine-containing acrylate emulsion prepared in step b, stirring, adding a photosensitizer during the stirring process and stirring evenly;

[0060] d. Preparation of surface hydrophobic coating: Perfluoroheptadecanetrimethyloxysilane is used as hydrophobic agent, added to isopropanol solution under stirring condition, dibutyltin dilaurate, hydrophobic nano SiO2 / TiO2 suspension, simethicone oil, stirred at room temperature for 2-4h, the surface hydrophobic coating is obtained;

[0061] e. Spraying of the underlying hydrophobic coating emulsion:

[0062] 1) Add the prepared mixture into the small pot of t...

Embodiment 1

[0068] Add 5g of nano-SiO2 to 500mL of xylene solvent, carry out ultrasonic dispersion for 20min, transfer to a three-necked flask and add 4.73g of perfluoro(heptadecafluoro)decyltrimethoxysilane as a modifier, and the modification temperature is 70°C , the reflux time is 8h, and the modified powder obtained by suction filtration is dried in a blast drying oven at 65°C for 4h;

[0069] The underlying hydrophobic coating material is based on 3.00g perfluorooctyl ethyl methacrylate, 0.55g methyl methacrylate, 1.24g 1,6-hexanediol diacrylate, 0.6g hydroxyethyl acrylate, 0.6gN,N -Methylenebisacrylamide, 5mL of hydroxy silicone oil to prepare mixed resin, add 40mL of deionized water and 1g of emulsifier to the reflux reactor, heat to 95°C under nitrogen protection, and drop it in 50-75min Add 20mL of ammonium persulfate solution and react for 90min under stirring at 300rpm;

[0070] The surface hydrophobic coating material is prepared according to the formula of 40g isopropanol, 1...

Embodiment 2

[0073] The difference between this embodiment and embodiment 1 is that TiO2 nanoparticles are selected as the particle material for constructing microscopic protrusions, and the particle size range is about 55-65 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com