Anti-freezing anti-cracking cement foaming heat preservation board

A cement foaming and thermal insulation board technology, applied in the field of thermal insulation building materials, can solve the problems of reducing the density of thermal insulation boards, poor frost resistance, high brittleness, etc., to improve toughness and impact resistance, improve flame retardant and heat resistance, good Effects of elasticity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

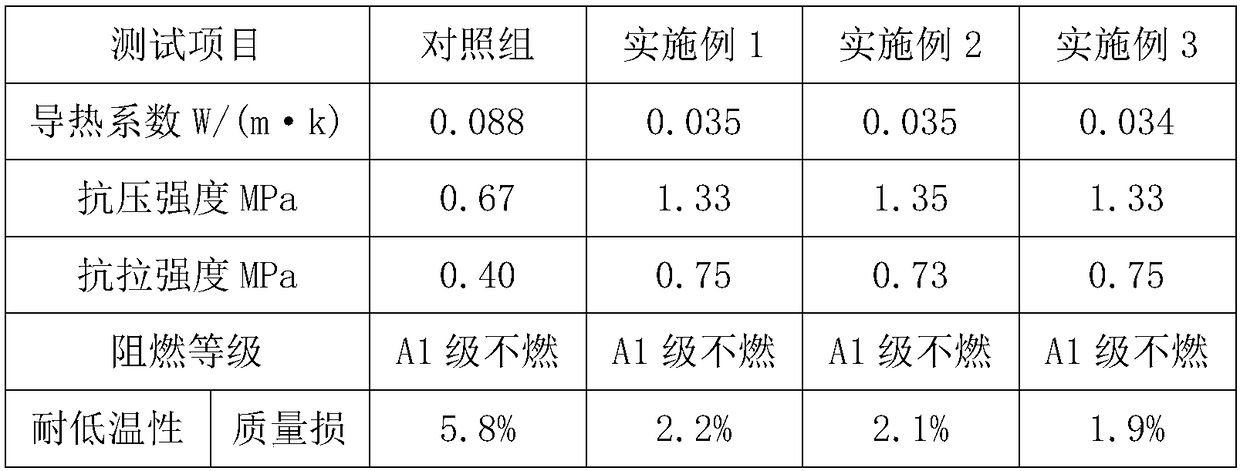

Embodiment 1

[0036]A frost-resistant and crack-resistant cement foam insulation board. According to the mass parts, the raw material components of the insulation board include: 70 parts of cement, 20 parts of fly ash, 10 parts of water glass, 10 parts of cold-resistant toughening agent, alumina fiber 4 parts, 7 parts of foaming agent, 1 part of foam stabilizer, 1 part of water reducer, 1.5 parts of antifreeze, 70 parts of water.

[0037] Wherein, the cement is a mixture of Portland cement and magnesium oxychloride cement in a mass ratio of 8:1; the water reducer is a lignin water reducer.

[0038] Foaming agent is hydrogen peroxide; Foam stabilizer is calcium stearate.

[0039] The antifreeze is a compound antifreeze compounded with propylene glycol butyl ether, ethylene glycol butyl ether acetate and diethylene glycol in a mass ratio of 1:2:5.

[0040] The preparation method of the insulation board provided by the present embodiment is:

[0041] According to the mass parts, add cement, ...

Embodiment 2

[0043] A frost-resistant and crack-resistant cement foam insulation board. According to the mass parts, the raw material components of the insulation board include: 90 parts of cement, 25 parts of fly ash, 15 parts of water glass, 20 parts of cold-resistant toughening agent, alumina fiber 7 parts, foaming agent 8 parts, foam stabilizer 2 parts, water reducing agent 2 parts, antifreeze agent 3.5 parts, water 80 parts.

[0044] Among them, the cement is a mixture of Portland cement and magnesium oxychloride cement in a mass ratio of 8:1; the water reducer is a polyhydroxy acid-based water reducer.

[0045] Foaming agent is hydrogen peroxide; Foam stabilizer is calcium stearate.

[0046] The antifreeze is a compound antifreeze compounded with propylene glycol butyl ether, ethylene glycol butyl ether acetate and diethylene glycol in a mass ratio of 1:2:5.

[0047] The preparation method of the insulation board provided by the present embodiment is:

[0048] According to the mass...

Embodiment 3

[0050] A frost-resistant and crack-resistant cement foam insulation board. According to the mass parts, the raw material components of the insulation board include: 80 parts of cement, 23 parts of fly ash, 12 parts of water glass, 16 parts of cold-resistant toughening agent, alumina fiber 5.7 parts, foaming agent 7.5 parts, foam stabilizer 1.4 parts, water reducing agent 1.5 parts, antifreeze agent 2.6 parts, water 75 parts.

[0051] Among them, the cement is a mixture of Portland cement and magnesium oxychloride cement in a mass ratio of 8:1; the water reducing agent is a melamine-based water reducing agent.

[0052] Foaming agent is hydrogen peroxide; Foam stabilizer is calcium stearate.

[0053] The antifreeze is a compound antifreeze compounded with propylene glycol butyl ether, ethylene glycol butyl ether acetate and diethylene glycol in a mass ratio of 1:2:5.

[0054] The preparation method of the insulation board provided by the present embodiment is:

[0055] Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com