Novel inorganic heat-insulating board prepared through normal-temperature foaming of perlite powder and preparation method thereof

A technology of inorganic insulation board and perlite powder, which is applied in the field of building exterior wall insulation materials, can solve the problems of small thermal conductivity, high thermal conductivity, and low compressive strength, and achieve good thermal insulation performance, high mechanical strength, and water resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

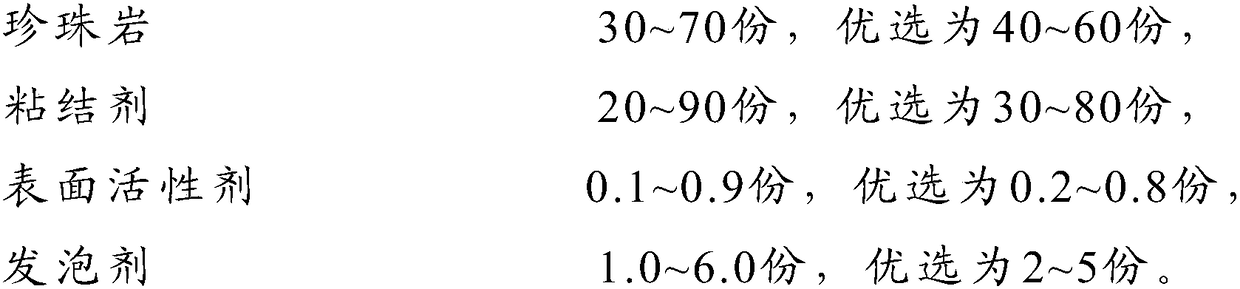

Method used

Image

Examples

Embodiment 1

[0096] Mix 50 parts of perlite powder or its tailings powder, 0.6 parts of sodium dodecyl sulfonate, and 0.8 parts of organosilicon hydrophobic powder, and then add 42 parts of water glass with a modulus of 3.2 and 4 parts of hydrogen peroxide, mix and stir evenly, to obtain a mixed material;

[0097] The obtained mixture was injected into the mold, leveled, covered with a perforated lid and foamed for 24 hours;

[0098] The foamed product was placed in a constant temperature oven, dried at 60°C for 24 hours, demolded after drying, and the demolded plate was placed in a muffle furnace and sintered at 500°C for 30 minutes;

[0099] The sintered plate was immersed in an organosilicon solution of organosilicon / water = 1 / 60 for 10 minutes, and finally the dipped plate was dried in a constant temperature drying oven at 60°C to obtain the final product.

[0100] The performance indicators of the sample are as follows: density=150kg / m 3 , compressive strength = 0.56MPa, thermal con...

Embodiment 2

[0102]Mix 50 parts of perlite powder or its tailings powder, 0.6 parts of sodium dodecyl sulfonate, 0.8 parts of silicone hydrophobic powder, and then add 42 parts of water glass with a modulus of 1.2 and 4 parts of hydrogen peroxide, mix and stir well , to obtain a mixed material;

[0103] The obtained mixture was injected into the mold, leveled, covered with a perforated lid and foamed for 24 hours;

[0104] The foamed product was placed in a constant temperature oven, dried at 60°C for 24 hours, demolded after drying, and the demolded plate was placed in a muffle furnace and sintered at 500°C for 30 minutes;

[0105] The sintered plate was immersed in an organic silicon solution of silicone / water = 1 / 60 for 10 minutes, and finally the immersed plate was dried in a constant temperature drying oven at 60°C.

[0106] The performance indicators of this sample are as follows: density=170kg / m 3 , compressive strength = 0.7MPa, thermal conductivity = 0.052W / (m·K), volume water a...

Embodiment 3

[0108] 50 parts of perlite powder or its tailings powder, 42 parts of modulus are the water glass of 3.2 molds, 0.2 part of CTAB, 4 parts of rock wool are mixed; Add 4 parts of hydrogen peroxide and mix and stir to obtain mixed material;

[0109] The obtained mixture was injected into the mold, leveled, covered with a perforated lid and foamed for 24 hours;

[0110] The foamed product was placed in a constant temperature oven, dried at 60°C for 24 hours, demolded after drying, and the demolded plate was placed in a muffle furnace and sintered at 500°C for 30 minutes;

[0111] The sintered plate was immersed in an organosilicon solution of organosilicon / water = 1 / 60 for 10 minutes, and finally the dipped plate was dried in a constant temperature drying oven at 60°C to obtain the final product.

[0112] The performance indicators of the sample are as follows: density=180kg / m 3 , compressive strength = 0.45MPa, thermal conductivity = 0.050W / (m·K), volume water absorption = 2%, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com