Single-slot cable clamp

A technology of single-slot line clamps and clamping blocks, which is applied in the direction of pipe supports, electrical components, pipes/pipe joints/pipe fittings, etc., and can solve problems such as energy loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

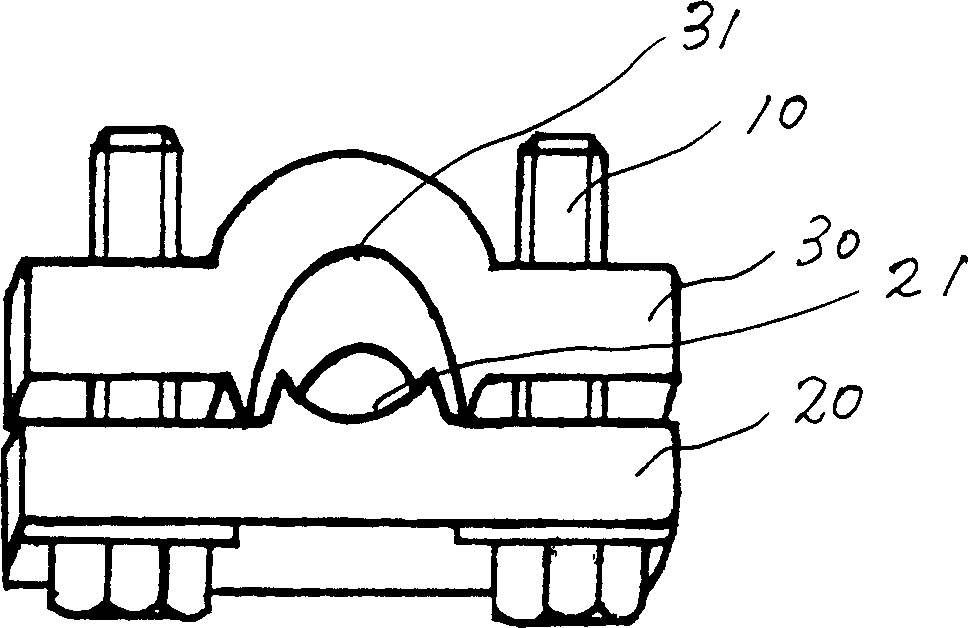

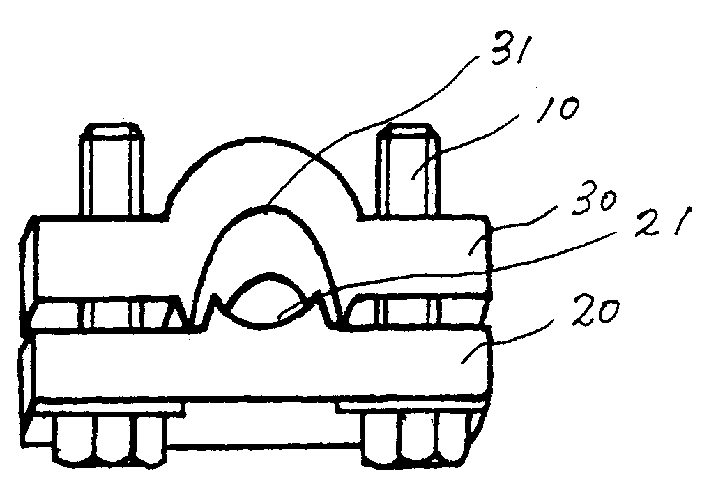

[0006] In the figure, a single-groove wire clamp is mainly composed of a compression bolt 10 and a lower clamping block 20. The compression bolt 10 penetrates into the screw hole of the lower clamping block 20, and the lower clamping block is provided with a raised U-shaped The clamping groove 21 is also screwed with a block-shaped upper clamping block 30 that is provided with a U-shaped clamping groove 31 matching the lower clamping block 20 on the compression bolt 10 . Among them, the upper and lower clamping blocks are made of high-strength copper. When in use, it is only necessary to tighten the bolts so that the upper clamping block matches the lower clamping block and clamps the wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com