Tensile-resistant cable clamp of aluminium alloy with high strength

A technology of tension-resistant clamp and aluminum alloy, which is applied in the direction of cable installation, adjustment/maintenance of mechanical tension, electrical components, etc., and can solve problems such as waste, material specificity, and energy loss

Inactive Publication Date: 2004-06-30

上海恒鼎电力器材有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The original strain clamps in our country are mainly made of malleable cast iron, which has a large specific gravity and heavy clamps. When constructing overhead cables, it is necessary to wrap the outer layer of the conductors with aluminum foil and fasten them with U-shaped bolts. As a result, a closed magnetic circuit is formed, hysteresis and eddy current are formed, resulting in energy loss and huge waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

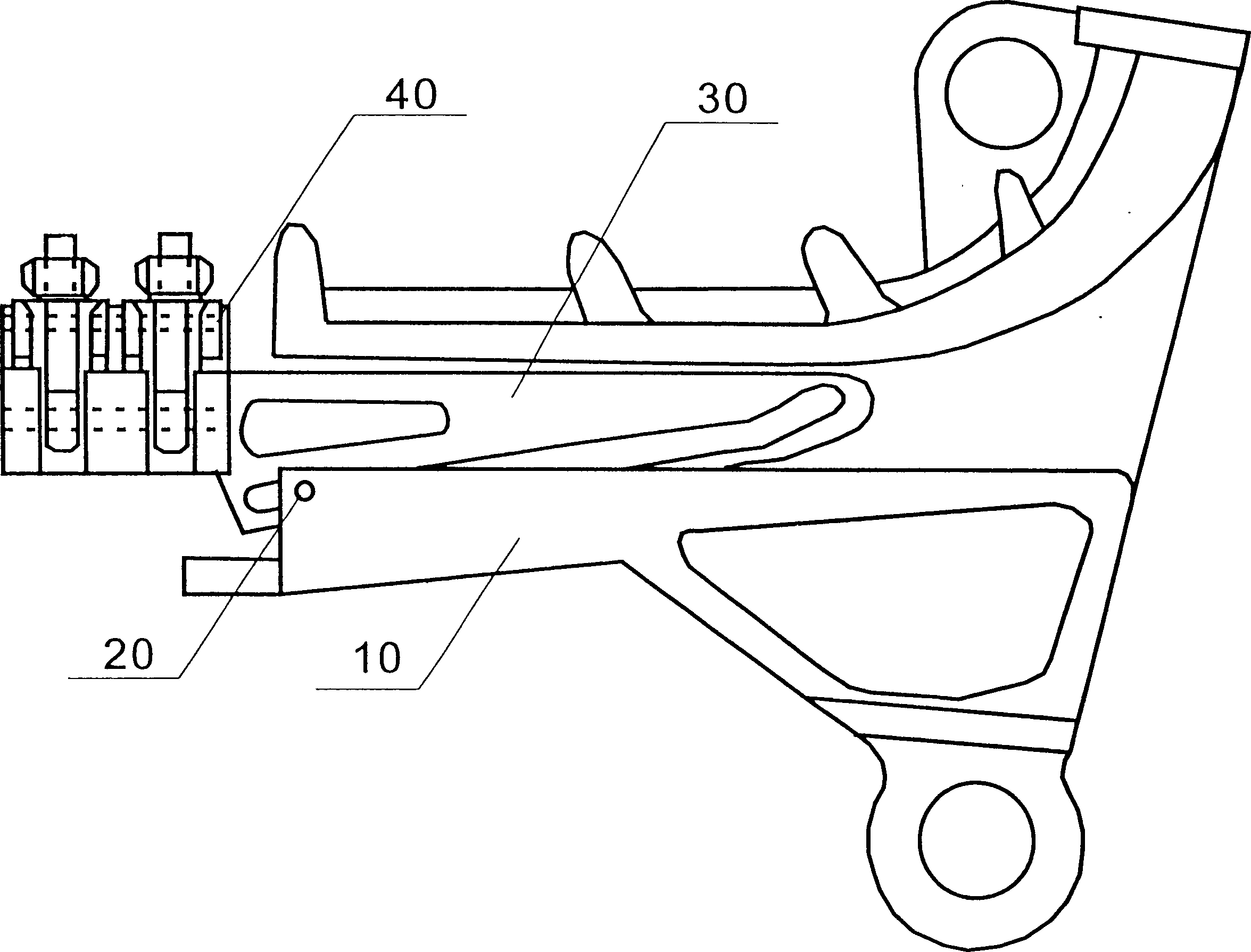

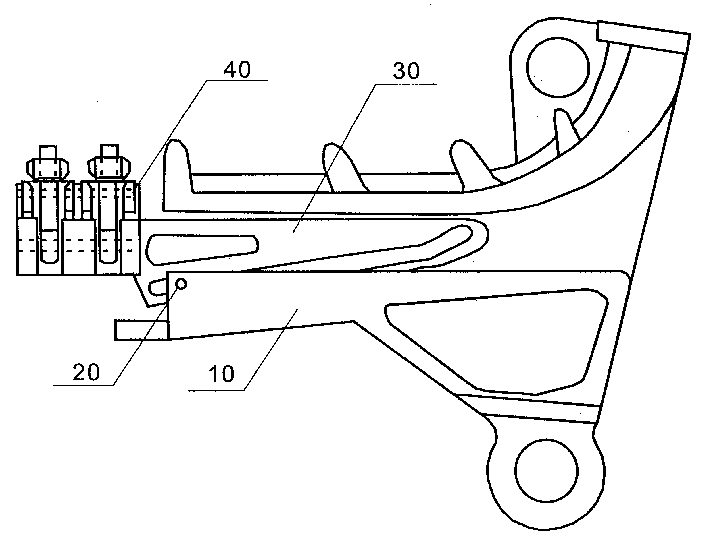

[0006] In the figure, the present invention is mainly composed of a body 10 and a wedge-shaped inner clamping block 30. On the body 10, corresponding to the position of the chute of the inner clamping block 30, an inner clamping limit pin 20 is provided, and a wire is provided at the end of the inner clamping block 30. Press block 40. Wherein the body 10 and the inner clamping block 30 are made of high-strength aluminum alloy.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The clamp comprises of body and inner fixture block. An inner clamping arresting pin is set up at the body corresponding to position of slideway in inner fixture block. The body and inner fixture block are made from high strength aluminium alloy. The invention lowers dissipation of energy, improving circuit equipment towards target of 'long service life, zero defects and exemption from inspection'.

Description

Technical field: [0001] The invention relates to electric equipment, in particular to a wire clamp suitable for distribution lines. Background technique: [0002] The original strain clamps in our country are mainly made of malleable cast iron, which has a large specific gravity and heavy clamps. When constructing overhead cables, it is necessary to wrap the outer layer of the conductors with aluminum foil and fasten them with U-shaped bolts. As a result, a closed magnetic circuit is formed, hysteresis and eddy current are formed, resulting in energy loss and huge waste. Invention content: [0003] The technical problem to be solved by the present invention is to provide a strain clamp made of high-strength aluminum alloy which can effectively overcome the above-mentioned defects and has remarkable energy-saving effect. The technical solution adopted by the present invention to solve the technical problem is that a strain clamp made of high-strength aluminum alloy is main...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02G7/00H02G7/02

Inventor 孙伟新

Owner 上海恒鼎电力器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com