Single cooling water tank new energy vehicle thermal management system

A thermal management system and technology for new energy vehicles, applied in the field of thermal management systems for new energy vehicles with a single cooling water tank, can solve problems such as inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the thermal management system for a new energy vehicle with a single cooling water tank according to the present invention will be described in detail below in conjunction with the accompanying drawings.

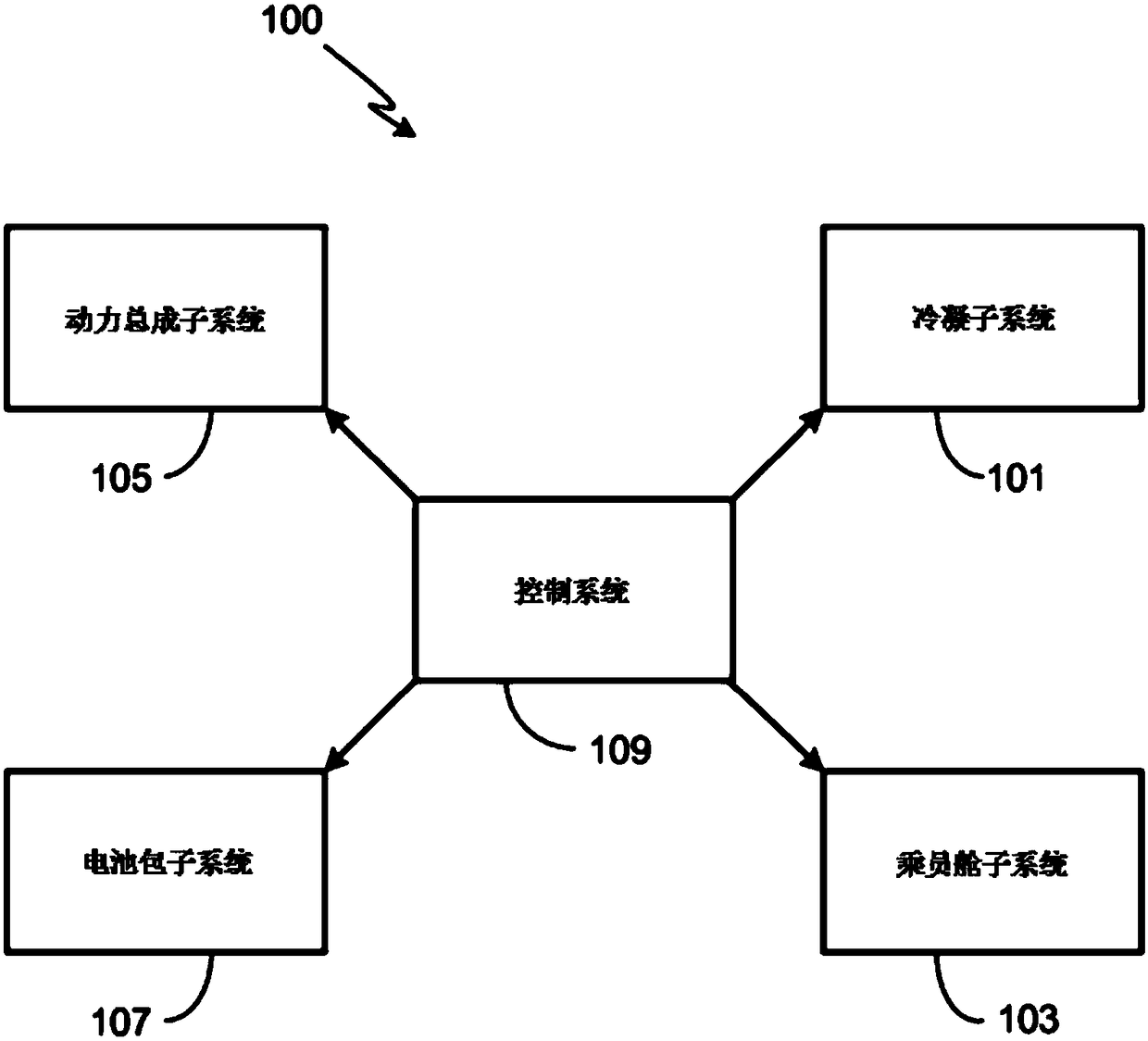

[0029] See attached figure 1 , 2 A thermal management system 100 for a new energy vehicle, especially a pure electric vehicle, includes a condensation subsystem 101 , a passenger compartment subsystem 103 , a powertrain subsystem 105 , and a battery pack subsystem 107 . The thermal management system 100 also requires a control system 109 . One or more of the other subsystems of the condensation subsystem 101 are thermally coupled together for the purpose of reducing the temperature of other thermal systems.

[0030] See attached figure 2 , the condensing subsystem 101 includes a compressor 201, which can compress the low-temperature refrigerating vapor in the condensing subsystem into high-temperature refrigerating vapor. When the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com