A kind of hot pressing sintering solidification method of arsenic sulfide slag

A technology of hot-pressing sintering and curing method, applied in chemical instruments and methods, removal of solid waste, transportation and packaging, etc., can solve problems such as safety risks in engineering implementation, achieve reduction of leaching toxicity, and have application prospects and promotion space. , the effect of reducing leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

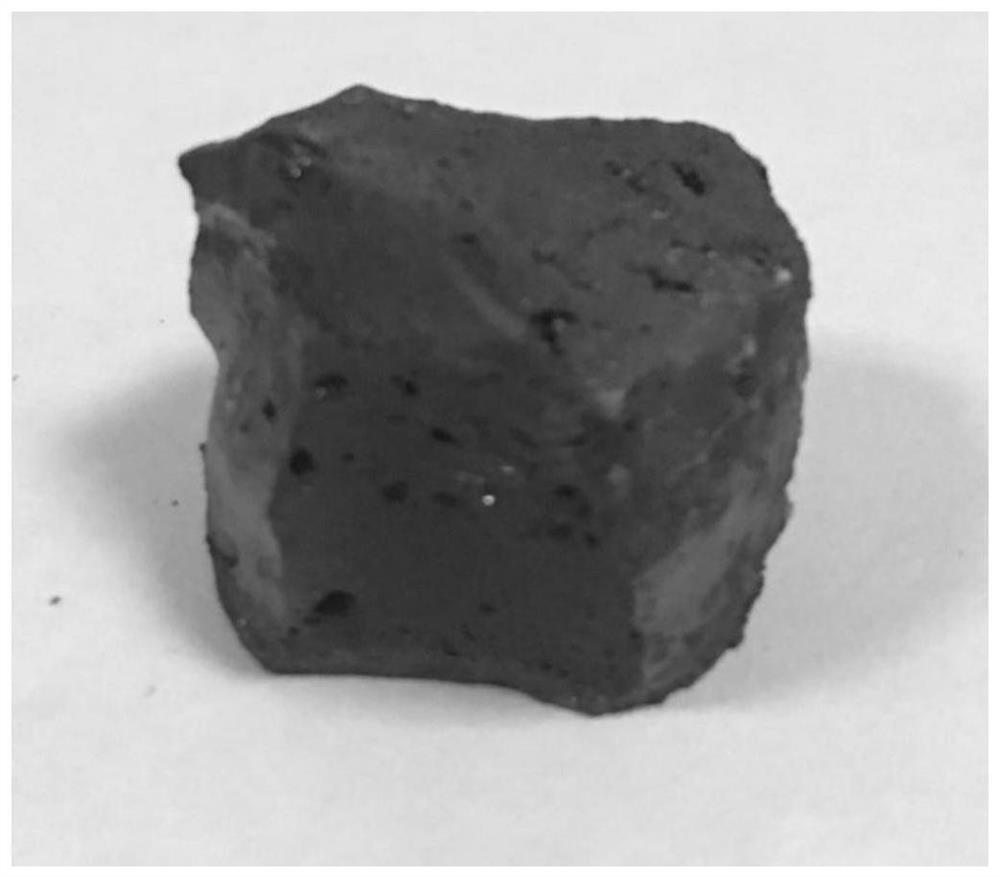

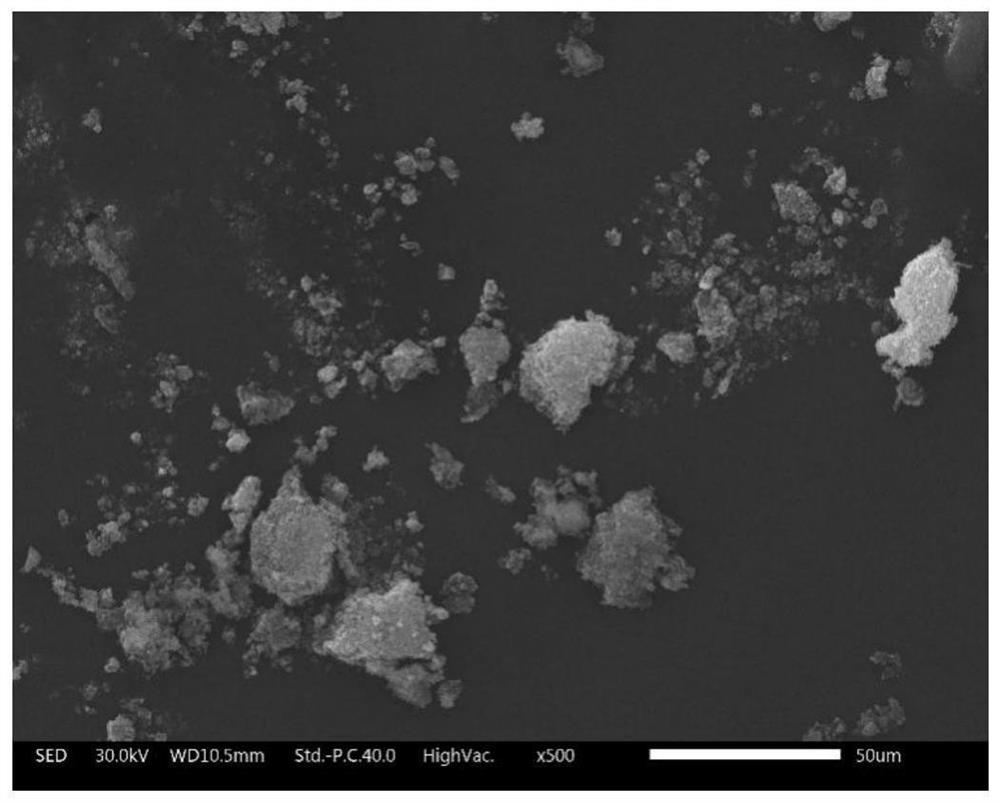

[0055] The arsenic sulfide slag produced by sulfuric acid sodium sulfide sulfidation treatment of a lead-zinc smelter in Hunan Province showed that the total element mass analysis mainly contained 35.2% As, 31.9% S, 0.15% Fe, 0.08% Zn, 0.23% Cu, 0.02% Sb, Pb 0.01%, the arsenic sulfide slag contains 72% water, and the acidity of the slag is 1.5%. Take 100g of slag, add 0.3g of lime, 0.6g of sodium carbonate, mechanically stir (500r / min) and react uniformly for 30min, the pH at the end of the reaction is 3.0, then protect and dry under nitrogen at 60°C, then add 60% of the weight of arsenic sulfide slag after drying % sulfur was mechanically mixed and stirred for 10 min. After mixing evenly, vibrate and compact, and briquette into shape. After the temperature reaches 140°C, keep warm at 6 MPa and pressurize for 6 hours, and then take out the sintered block after the temperature drops to room temperature. The appearance of arsenic sulfide slag before and after treatment and the ...

Embodiment 2

[0062] Combined with the optimal conditions of Example 1 above, the arsenic sulfide slag produced by the sulfuric acid hydrogen sulfide treatment of a copper smelter in Yunnan was taken, and the mass analysis of all elements showed that it mainly contained As 39.2%, S 22.9%, Fe 0.81%, and Zn 0.60%. , Cu0.53%, Sb 0.30%, Pb 0.10%, the arsenic sulfide slag contains 77% water, and the slag acidity is 1.5%. Take 100g of slag, add 0.6g of calcium carbonate, 0.3g of lime, mechanically stir (500r / min) and react for 30min evenly, the pH of the reaction end point is 3.5, then protect and dry under nitrogen at 60°C, then add 60% of the weight of arsenic sulfide slag after drying % sulfur, mechanically mixed and stirred for 10min. After mixing evenly, vibrate and compact, 6MPa briquetting is formed, after the temperature reaches 160°C, keep the temperature at 6MPa and hold the pressure for 6h, and then take out the sintered block after the temperature drops to normal temperature. The app...

Embodiment 3

[0064] Combined with the optimal conditions of the above example 1, the arsenic sulfide slag produced by a copper smelter in Anhui from the sulfuric acid hydrogen sulfide sulfidation treatment showed that the total element mass analysis mainly contained 25.7% As, the arsenic sulfide slag contained 35% water, and the acidity of the slag was 0.8 %. Take 100g of slag, add 0.6g of calcium carbonate, 0.3g of lime, mechanically stir (500r / min) and react for 30min evenly, the pH of the reaction end point is 3.5, then protect and dry under nitrogen at 60°C, then add 60% of the weight of arsenic sulfide slag after drying % sulfur, mechanically mixed and stirred for 10min. After mixing evenly, vibrate and compact, 6MPa briquetting is formed, after the temperature reaches 160°C, keep the temperature at 6MPa and hold the pressure for 6h, and then take out the sintered block after the temperature drops to normal temperature. The appearance of arsenic sulfide slag before and after treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com