Rapidly-molded microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic and fast technology, applied in the field of microwave dielectric ceramic manufacturing, can solve the problems of toxicity, poor sample uniformity, and internal bubble holes, etc., and achieve the effect of excellent performance, excellent performance, and improved green strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

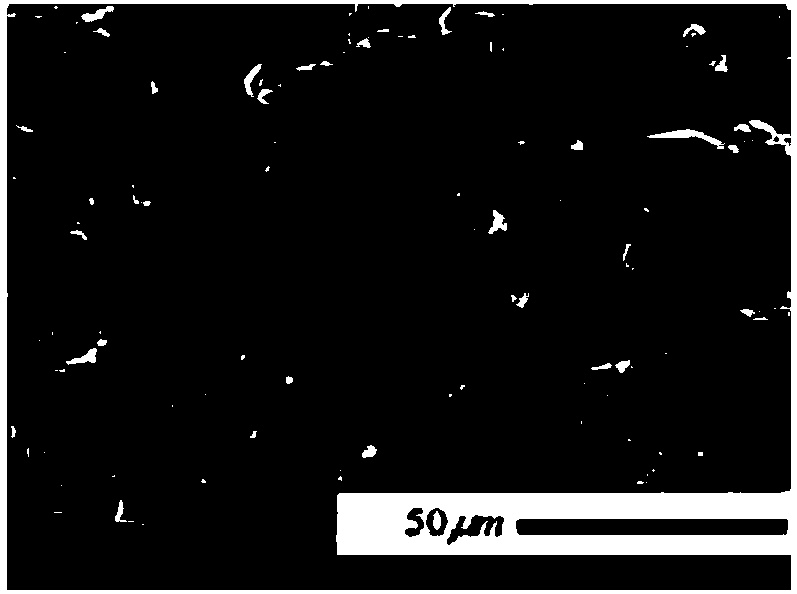

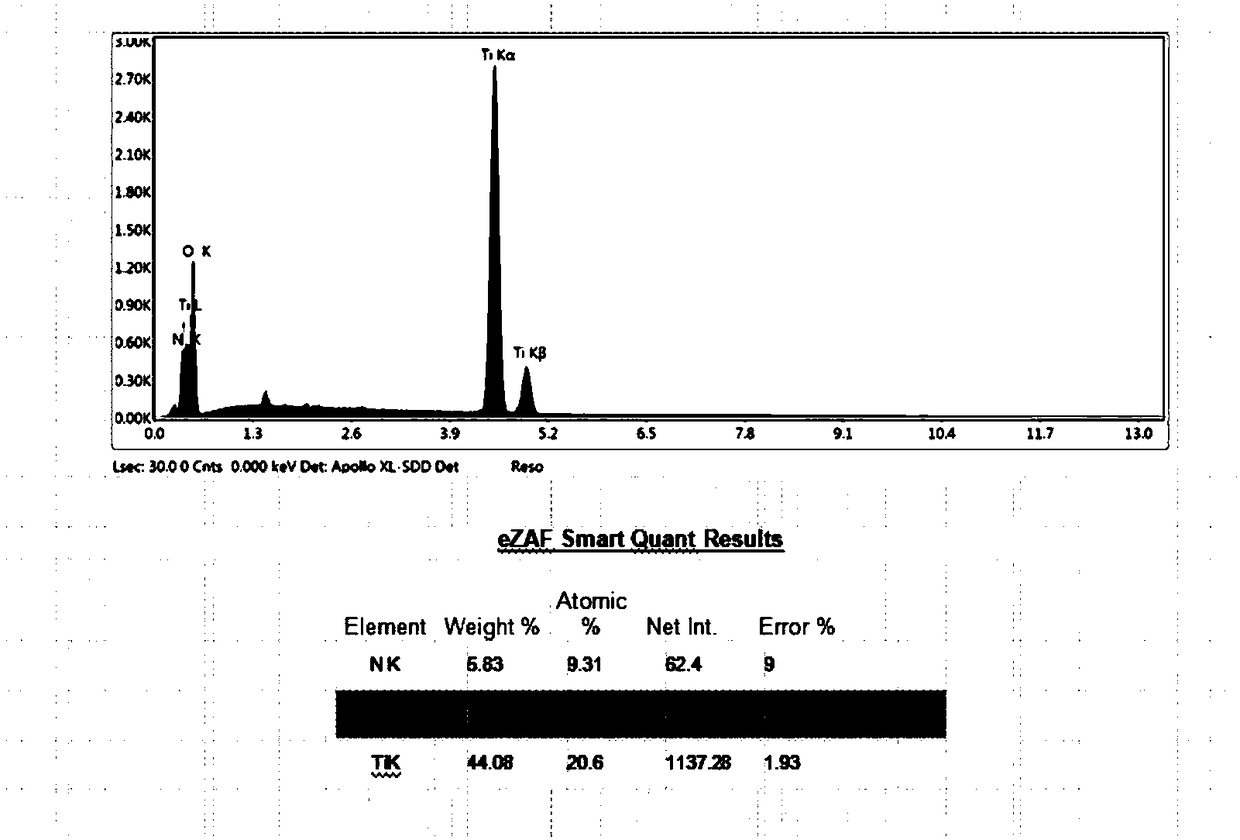

Image

Examples

preparation example Construction

[0037] A preparation method for rapid prototyping microwave dielectric ceramics, comprising the following steps:

[0038] Step 1), take the raw materials according to the ratio of mass and number: ceramic powder: deionized water = (18-22): (23-27);

[0039] Step 2), taking the biomolecular crosslinking agent, plasticizer and lubricant are respectively 0.5-1%, 0.06-0.16% and 0.1-0.4% of the quality of deionized water, and the biomolecular crosslinking agent and plasticizer are simultaneously Add part of deionized water, stir evenly at 75°C-90°C, then add a pH regulator to adjust the pH value to 8-10 to obtain mixture A;

[0040] Step 3), cooling mixture A to 60°C-65°C, adding lubricant and stirring to obtain mixture B;

[0041] Step 4), after mixing the ceramic powder and the remaining deionized water evenly, add it to the mixture B, and mix evenly to obtain the mixture C;

[0042] Step 5), the mixture C is continuously stirred until it is viscous, and then poured into a mold...

Embodiment 1

[0053] (1) Take 25g of deionized water 14g and 11g in two bottles, then take 0.16g of agarose and 0.025g of ethylene glycol, add 14g of deionized water and heat on a magnetic stirrer, set the temperature to 75 ° C, use a dropper Take 0.025g of ethylene glycol reagent into a small beaker, and then add the weighed agarose powder to avoid sticking to the wall of the cup; ethylene glycol will form a hydrogen bond with the agarose in the solution and act as a plasticizer to improve the green body. Intensity, finally add ammonia water to adjust the mixed solution to pH = 9, and put it on a magnetic stirrer, set the temperature at 85°C, and rotate at 200r / min to completely dissolve the agarose to obtain mixture A;

[0054] (2) When the small particles in it obviously disappear, it means that the agarose has been completely dissolved. Cool down the mixture A when the temperature reaches 65°C, add 0.05g of ethanol and continue to stir until it is uniform to obtain the mixture B. It pla...

Embodiment 2

[0063] (1) Take 25g deionized water 14g and 11g in two bottles, then take 0.16g gelatin and 0.025g ethylene glycol, add 14g deionized water and heat it on a magnetic stirrer, set the temperature at 80°C, and take it with a dropper Add 0.025g of ethylene glycol reagent into the small beaker, then add the weighed gelatin powder to avoid sticking to the cup wall; ethylene glycol will form hydrogen bonds with gelatin in the solution, as a plasticizer to improve the green body strength, and finally Add lithium hydroxide to adjust the mixed solution to pH = 9, and place it on a magnetic stirrer with a set temperature of 85°C and a rotational speed of 200r / min to completely dissolve the gelatin to obtain a mixture A;

[0064] (2) When the small particles in it obviously disappear, it means that the gelatin has been completely dissolved. Cool the mixture A when the temperature reaches 65°C, add 0.05g lithium hydroxide and continue to stir until it is uniform to obtain the mixture B. Et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com