High-temperature nickel-based alloy multistage filter and manufacturing method thereof

A nickel-based alloy, stage filter technology, applied in gravity filters, chemical instruments and methods, fixed filter element filters, etc., can solve the problem of insufficient corrosion resistance and high temperature resistance, large flow resistance and pressure drop, and limited shape changes. and other problems, to achieve the effect of strong high temperature resistance, reduced flow resistance, and low fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

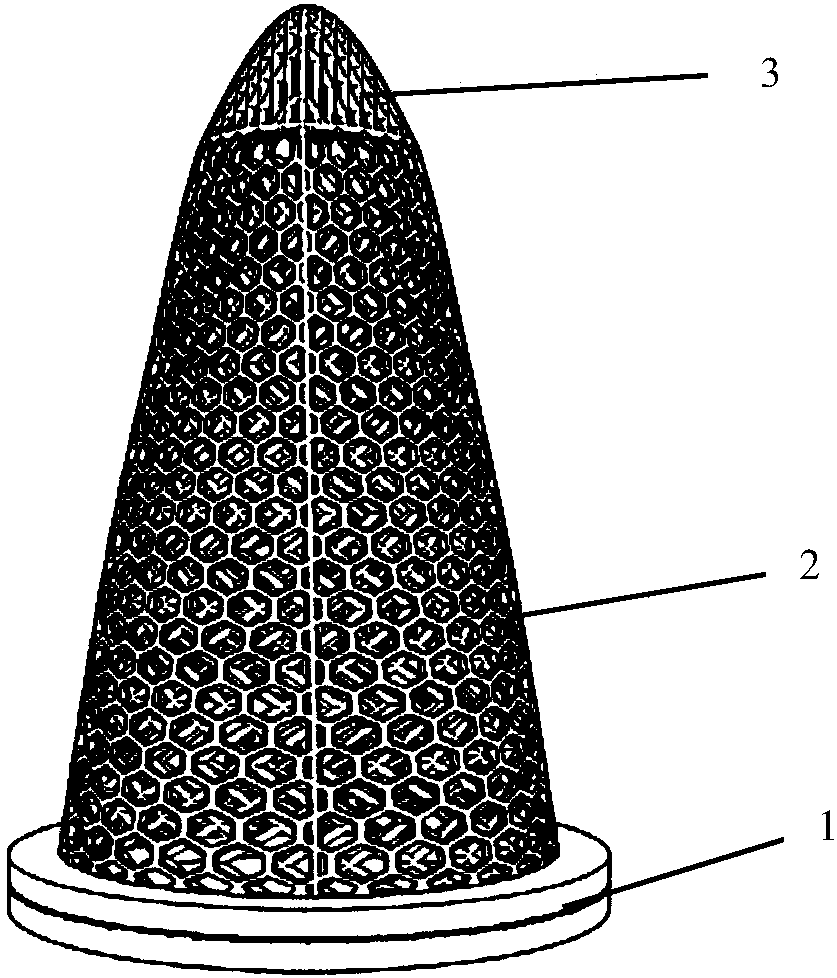

[0046] Such as Figure 1-2shown. The invention discloses a high-temperature nickel-based alloy multistage filter, which comprises a multistage porous filter medium body and a sealing interface section 1; the multistage porous filter medium body is connected to a pipeline through the sealing interface section 1; the multistage porous filter The medium body is composed of two layers of porous filter medium inside and outside, and they both include the middle section 2 of the porous filter medium body and the head 3 of the porous filter medium body;

[0047] In these two layers of porous filter medium bodies, the outer layer is the first-stage porous filter medium layer, and the inner layer is the second-stage porous filter medium layer; The shape of the filter holes in the medium layer is different;

[0048] The sizes of the filter holes of the first-stage porous filter medium layer and the filter holes of the second-stage porous filter medium layer are gradually reduced from ...

Embodiment 2

[0072] This embodiment is the same as Embodiment 1 except for the following features.

[0073] 500-mesh high-temperature nickel-based alloy powder is selected as the material, and the processing parameters are: laser power 150W, laser spot 50μm, scanning speed 900mm / s, forming layer thickness 30μm, and laser scanning distance 0.08mm.

[0074] In this embodiment, the density between the two-stage porous filter medium layers is 99%, and the porosity is respectively 44.4% in the first stage and 39.1% in the second stage.

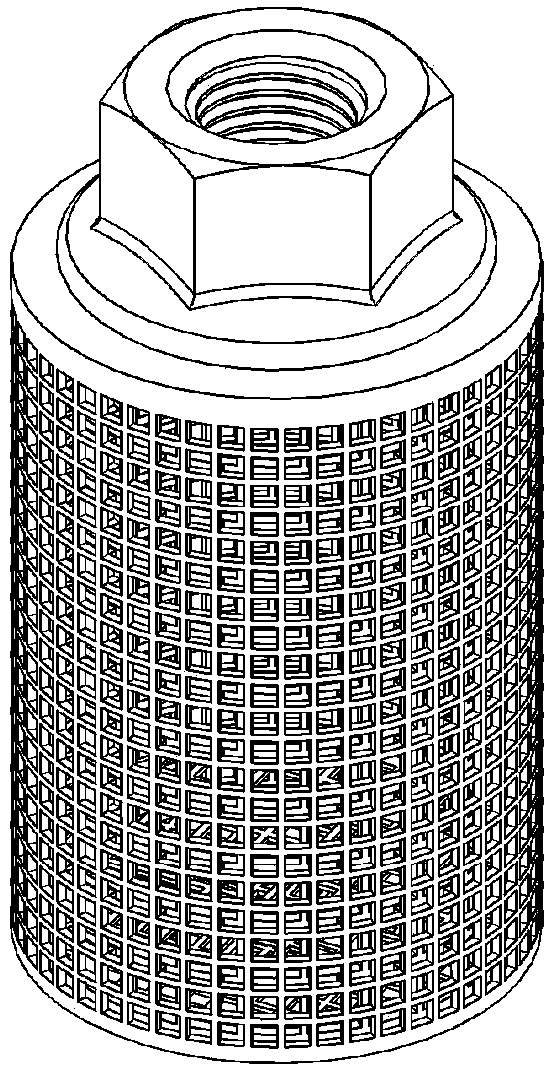

[0075] In this embodiment, each stage of porous filter structure in the two-stage porous filter medium layer is a square porous structure; the diameter of the circumscribed circle of the cross-section of the metal wire / metal pillar of the first-stage porous filter medium layer is 100 μm, and the diameter of the circumscribed circle of the second-stage porous filter medium layer is 100 μm. The dielectric layer is 60μm.

[0076] In this embodiment, both the maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com