NdFeB sintered magnet with coating and preparation method thereof

A technology of sintered magnets and NdFeB, applied in coatings, magnetic objects, inductors/transformers/magnets, etc., can solve problems such as excessive use of heavy rare earth Dy and Tb, rapid degradation of NdFeB structure, and degradation of magnet performance. The effect of stable product quality, promotion of balanced utilization of rare earth resources, and reduction of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

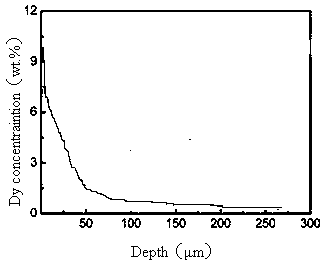

[0031] Take NdFeB sintered magnets as the anode, and perform electrophoresis pretreatment on the anode, and use the steel plate as the cathode, and make the particle size 0.7 micron DyF 3 The powder is mixed into an organic solvent to make an electrophoretic solution. The organic solvent is composed of industrial ethanol, ethyl acetate, and industrial methanol, and its volume ratio is 9:0.5:0.5. DyF in the electrophoretic solution 3The concentration of the powder is 5g / L, and the DC power supply is turned on at a DC voltage of 30V for electrophoretic deposition, and then the sintered NdFeB magnet is removed from the electrophoretic solution and dried; the obtained coating sample is diffused at 700°C , lasted 7h, followed by annealing at 400°C for 1h under vacuum conditions, and finally a magnet was obtained.

Embodiment 2

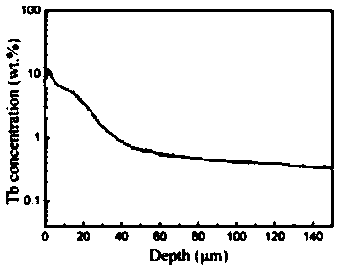

[0033] Take NdFeB sintered magnets as the anode, and carry out electrophoresis pretreatment on the anode, and the steel plate as the cathode, and the particle size is 0.6 micron TbF 3 The powder is mixed into an organic solvent to make an electrophoretic solution. The organic solvent is composed of industrial ethanol and ethyl acetate, and its volume ratio is 9:1. TbF in the electrophoretic solution 3 The concentration of the powder is 5.5g / L, and the DC power is turned on at a DC voltage of 30V for electrophoretic deposition, and then the NdFeB sintered magnet is removed from the electrophoretic solution and dried; the obtained coating sample is processed at 710 ° C Diffusion lasted for 8h, followed by annealing at 420°C for 2h under vacuum, and finally a magnet was obtained.

Embodiment 3

[0035] Sintered NdFeB magnets are used as anodes, and the anodes are subjected to electrophoresis pretreatment, steel plates are used as cathodes, and the particle size is 0.67 microns DyF 3 The powder is mixed into an organic solvent to make an electrophoretic solution. The organic solvent is composed of industrial ethanol and industrial methanol, and its volume ratio is 9:1. DyF in the electrophoretic solution 3 The concentration of the powder is 5g / L, and the DC power supply is switched on at a DC voltage of 30V for electrophoretic deposition, and then the sintered NdFeB magnet is removed from the electrophoretic solution and dried; the obtained coating sample is diffused at 720°C , lasted 7h, followed by annealing at 430°C under vacuum for 1h, and finally a magnet was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com