Lubricating grease special for gears and racks of automobile steering device and preparing method of lubricating grease

An automobile steering gear, rack and pinion technology, applied in the field of lubricating grease, can solve problems such as short lubrication life, poor anti-friction effect, narrow operating temperature range, etc., and achieve the effects of improving high temperature performance, long service life, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

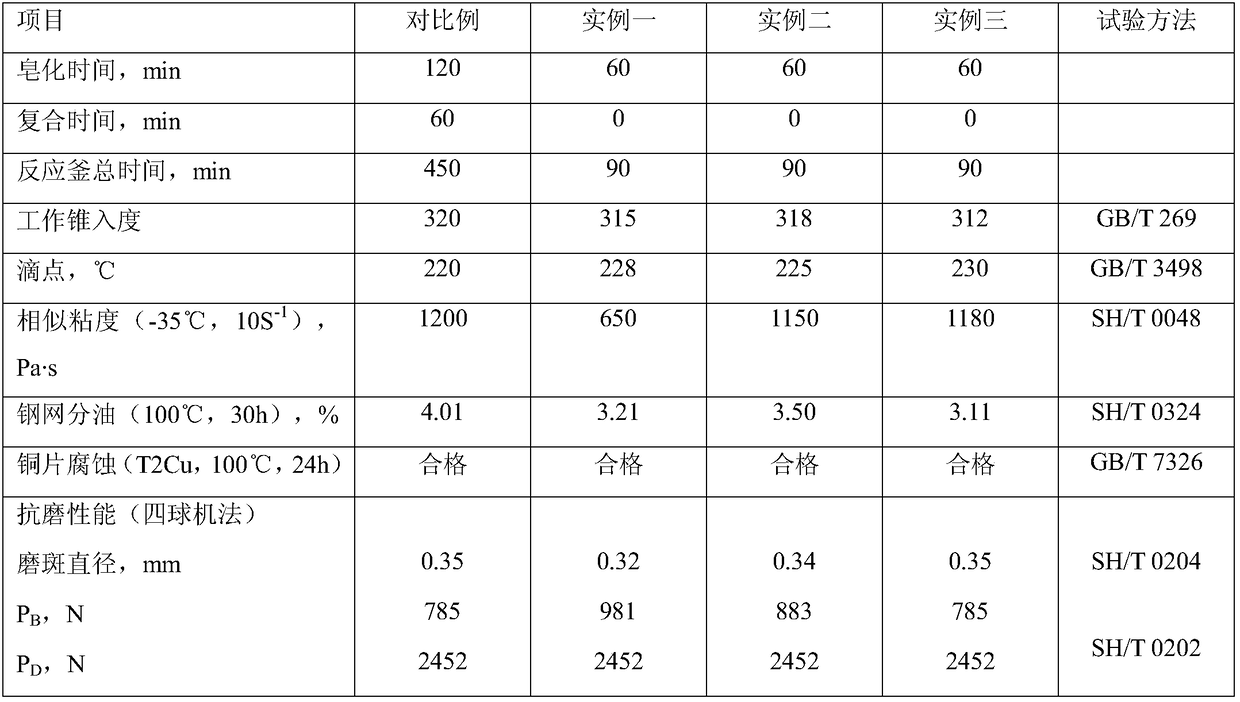

Examples

preparation example Construction

[0030] A kind of preparation method of special lubricating grease for gear and rack of automobile steering gear adopts the following process steps:

[0031] (1) Add base oil and 12-hydroxystearic acid, which account for 1 / 3 of the total amount of base oil, into the reactor, stir and heat up to 75-85°C, and after the 12-hydroxystearic acid is completely melted, add hydrogen monohydrate Lithium oxide powder and boric acid, closed reaction kettle;

[0032] (2) Control the pressure relief valve to keep the pressure in the kettle within 0.45-0.55MPa, raise the temperature to 215°C, and keep it at this temperature for 20min;

[0033] (3) After the pressure is released, put an appropriate amount of base oil into the reactor to lower the temperature in the reactor to about 180°C, and then transfer the materials to the blender;

[0034] (4) Add the remaining base oil to cool down, and homogenize under the conditions of 80-90°C and 15-25MPa;

[0035] (5) Cooling down to below 80°C, ad...

Embodiment 1

[0038] Put 1000kg of base oil PAO9 and 270kg of lauryl hydroxystearic acid into the reactor, heat the reactor to 85°C, after the lauryl hydroxystearic acid is dissolved, add 50kg of lithium hydroxide powder into the reactor and 15kg of boric acid. Control the pressure in the kettle at 0.45-0.55MPa, rapidly raise the temperature to 213-217°C, and keep it for 20min. Then release the pressure in the kettle, add 600kg of base oil PAO9, cool down to below 180°C, and transfer to the blending kettle. Add 905kg of base oil PAO9 to cool down. At 90°C, homogenize for 2 hours under a pressure of 20MPa. When the temperature of the material drops to 80°C, add 15kg of octyl / butyl diphenylamine, 15kg of Methyl phenol, 20kg barium dinonylnaphthalene sulfonate, 30kg zinc dialkyldithiophosphate and 80kg molybdenum dialkylthiocarbamate, cyclically filtered and degassed to obtain the finished product.

Embodiment 2

[0040] Put 1000kg of 8cst III base oil and 270kg of lauryl hydroxystearic acid into the reactor, heat the reactor to 85°C, after the dodecyl hydroxystearic acid is dissolved, add 50kg of lithium hydroxide powder into the reactor and 15kg boric acid. Control the pressure in the kettle at 0.45-0.55MPa, rapidly raise the temperature to 213-217°C, and keep it for 20min. Then release the pressure in the kettle, add 600kg of 8cst III base oil, cool down to below 180°C, and transfer to the blending kettle. Add 900kg of base oil PAO9 to cool down. At 90°C, homogenize for 2 hours under a pressure of 20MPa. When the material temperature drops to 80°C, add 15kg of octyl / butyl diphenylamine, 15kg of 3,5-di-tert- n-octadecyl 4-hydroxyphenylpropionate, 10kg barium dinonylnaphthalenesulfonate, 5kg benzotriazole, 30kg dialkylmolybdenum dithiophosphate and 90kg dialkylthiocarbamate Antimony, circulating filtration, degassing to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com