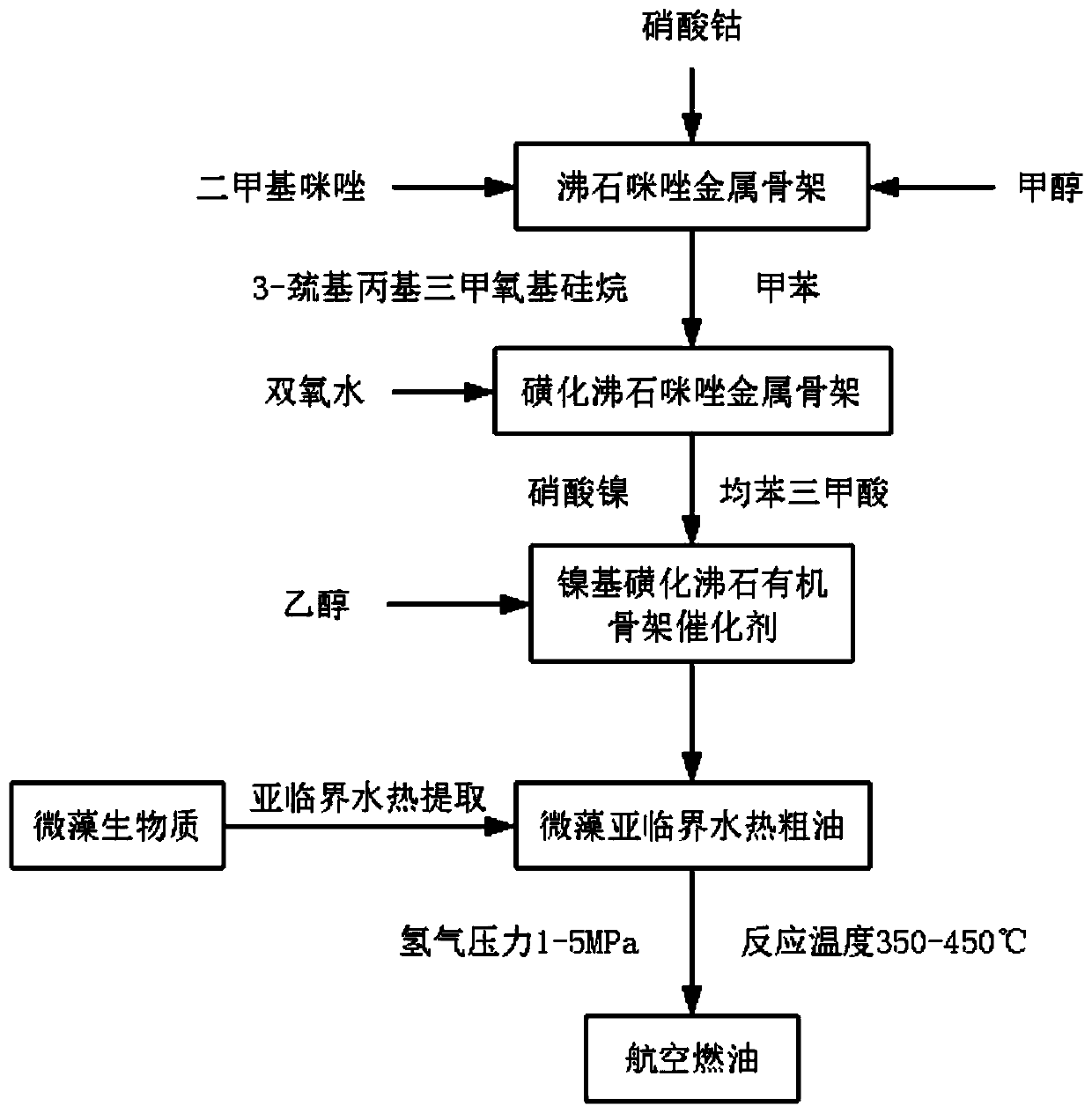

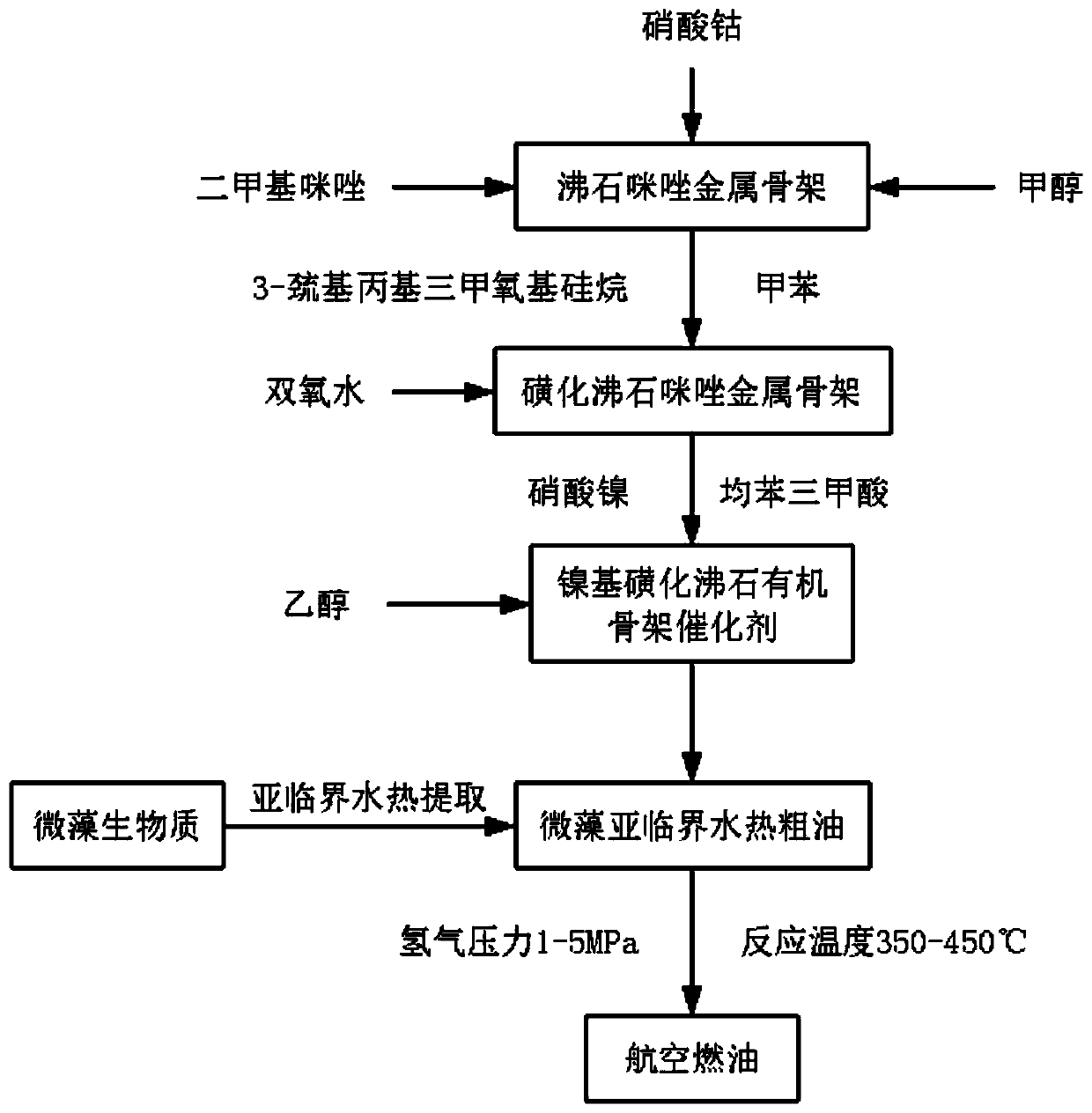

Hydrothermal Preparation of Jet Oil from Algae Oil Catalyzed by Ni-based Sulfonated Zeolite Organic Framework

An organic framework and sulfonated zeolite technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Solve problems such as sintering and reduce catalyst life, achieve the effect of improving hydrothermal stability and anti-poisoning ability, maintaining structural integrity, and facilitating storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 0.72gCo(NO 3 ) 2 ·6H 2 O and 1.63g dimethylimidazole were dissolved in 50mL methanol respectively, and the two solutions were stirred with a magnetic stirrer at 100rpm for 2min, and then the Co(NO 3 ) 2 ·6H 2 O methanol solution was poured into dimethylimidazole methanol solution, and the mixed solution was placed in an ultrasonic oscillator and mixed for 30 min. After the solution is fully reacted, use a high-speed refrigerated centrifuge to centrifuge to synthesize the zeolite imidazole metal framework.

[0030] Add 0.5 g of zeolite imidazole metal skeleton and 10 mL of toluene into a three-necked flask, place in an oil bath and raise the temperature to 90° C., and stir for 0.5 h under a nitrogen atmosphere. Then 0.1 mL of 3-mercaptopropyltrimethoxysilane was weighed and added to the above mixed solution, and the stirring was continued for 12 h. Then the mixture was suction filtered, washed once with ethanol, and dried in an oven at 50 °C for 4 h. Weigh the mas...

Embodiment 2

[0034] 7.2gCo(NO 3 ) 2 ·6H 2O and 16.3g dimethylimidazole were dissolved in 500mL methanol respectively, and the two solutions were stirred with a magnetic stirrer at a speed of 500rpm for 20min, and then the Co(NO 3 ) 2 ·6H 2 O methanol solution was poured into dimethylimidazole methanol solution, and the mixed solution was placed in an ultrasonic oscillator and mixed for 30 min. After the solution is fully reacted, use a high-speed refrigerated centrifuge to centrifuge to synthesize the zeolite imidazole metal framework.

[0035] Add 5 g of zeolite imidazole metal skeleton and 100 mL of toluene into a three-neck flask, place in an oil bath and raise the temperature to 120° C., and stir for 2 h under a nitrogen atmosphere. Then 4 mL of 3-mercaptopropyltrimethoxysilane was weighed and added to the above mixed solution, and the stirring was continued for 48 h. Then the mixture was suction-filtered, washed with ethanol for 5 times, and dried in an oven at 90°C for 10 h. W...

Embodiment 3

[0039] 3.6gCo(NO 3 ) 2 ·6H 2 O and 8.15g dimethylimidazole were respectively dissolved in 250mL methanol, and the two solutions were stirred with a magnetic stirrer at 300rpm for 10min, and then the Co(NO 3 ) 2 ·6H 2 O methanol solution was poured into dimethylimidazole methanol solution, and the mixed solution was placed in an ultrasonic oscillator and mixed for 30 min. After the solution is fully reacted, use a high-speed refrigerated centrifuge to centrifuge to synthesize the zeolite imidazole metal framework.

[0040] Add 2.5 g of zeolite imidazole metal skeleton and 50 mL of toluene into a three-necked flask, place in an oil bath and raise the temperature to 100° C., and stir for 1 h under a nitrogen atmosphere. Then 2 mL of 3-mercaptopropyltrimethoxysilane was weighed and added to the above mixed solution, and the stirring was continued for 24 h. Then the mixture was suction-filtered, washed with ethanol for 3 times, and dried in an oven at 70 °C for 6 h. Weigh th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com