Preparation method of dense anti-corrosion conductive coating

A kind of anti-corrosion, conductive and dense technology, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problem of inability to balance anti-corrosion performance and electrical conductivity, and achieve enhanced mechanical properties, improved mechanical strength, and improved dense structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

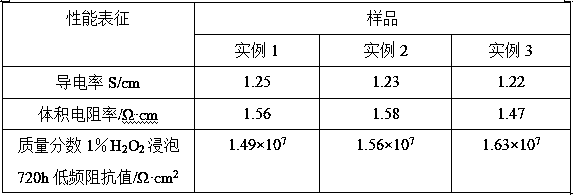

Examples

Embodiment Construction

[0017] In terms of parts by weight, weigh 45-50 parts of deionized water, 10-15 parts of phosphoric acid and 6-8 parts of aluminum hydroxide in a beaker, stir and mix and heat in an oil bath at 100-120°C for 25- After 30 minutes, the mixed solution was obtained, and according to the mass ratio of 1:8, the mass fraction of 5% phosphoric acid solution was added dropwise to the mixed solution, and the dropping rate was controlled at 2-3mL / min. 5h, get the matrix liquid and weigh 45-50 parts of the matrix liquid, 3-5 parts of boric acid, and 10-15 parts of citric acid respectively in a beaker, stir and mix, and place in a water bath at 75-85 °C Heating for 25 to 30 minutes, standing and cooling to room temperature to obtain the modified bonding liquid; according to the mass ratio of 1:5:8, add 200 mesh bentonite and 200 mesh graphite particles to the modified bonding liquid, grind and disperse, and collect the dispersed slurry. Obtain the bonding slurry; in parts by weight, weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com