Functionalized graphene flame retardant and polylactic acid composite material enhanced by functionalized graphene flame retardant

A composite material and flame retardant technology, which is applied in the field of flame retardant composite materials, can solve the problems of limiting the application of flame retardants and the destruction of physical and mechanical properties of composite materials, and achieve the goal of improving dispersion, improving flame retardant performance, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

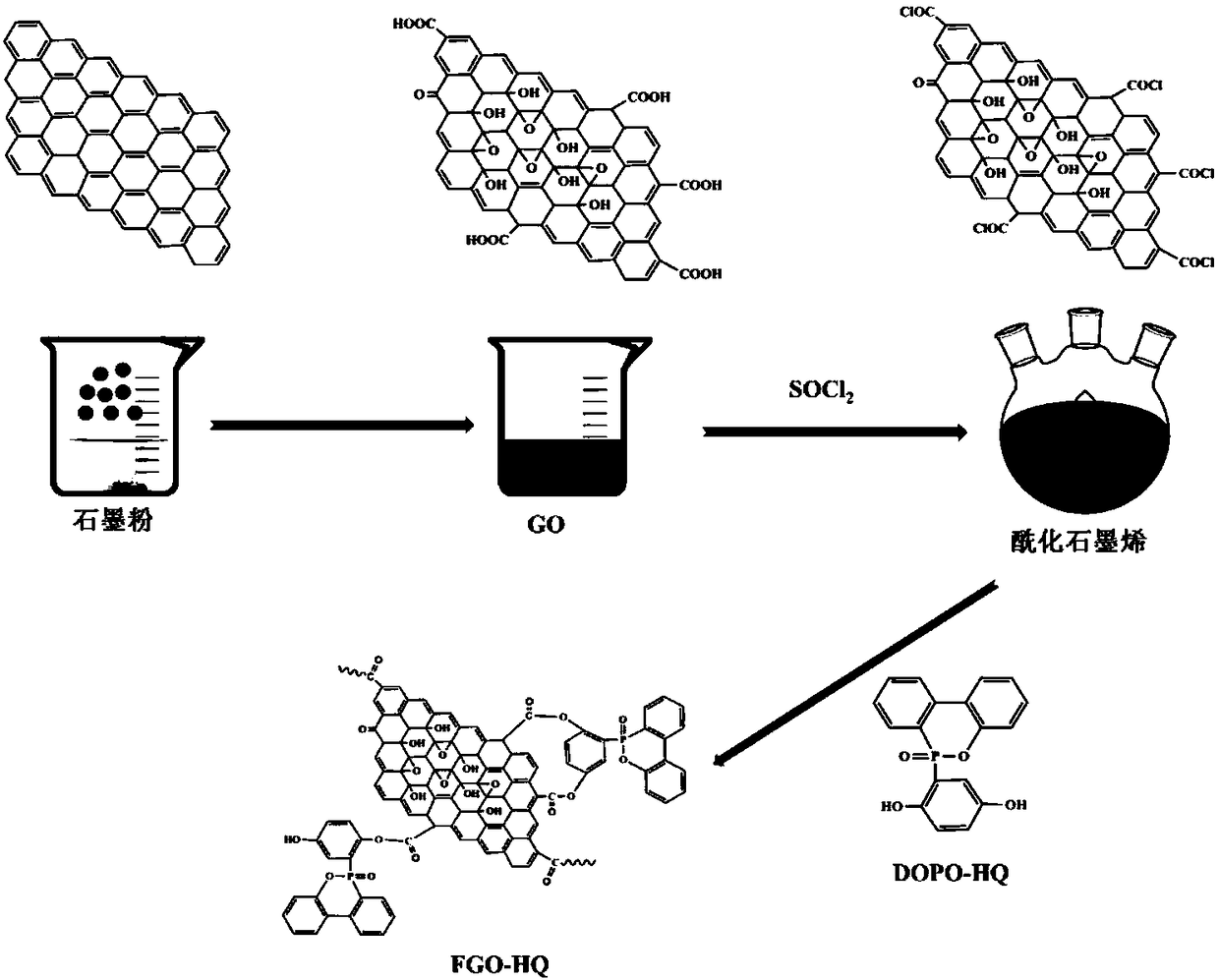

[0033] (1) Dissolve 2g of graphene oxide (GO, prepared by the Hummers method using natural graphite, sodium nitrate and potassium permanganate as raw materials) in 100mL of tetrahydrofuran, add 250mL of thionyl chloride after complete dissolution and Stirred and refluxed in an oil bath for 6h. After the reaction was completed, it was cooled to room temperature, filtered, washed with deionized water until neutral, and vacuum-dried at 80° C. for 8 h to obtain an intermediate product.

[0034] (2) The intermediate product and 19.542g 10-(2,5-dihydroxyphenyl)-9,10-dihydro-9-oxa-10-phosphinephenanthrene-10-oxide (DOPO-HQ) were added to 300mL chlorobenzene solution was stirred and refluxed in an 85°C oil bath for 10h, and then the resulting precipitate was cooled to room temperature, filtered, and dried to obtain a functionalized graphene flame retardant (FGO-HQ).

Embodiment 2

[0036] (1) Dissolve 0.5g graphene oxide (GO, prepared by Hummers method using natural graphite, sodium nitrate and potassium permanganate as raw materials) in 100mL N,N-dimethylformamide, and add 100mL of thionyl chloride was stirred and refluxed in an oil bath at 65°C for 8h. After the reaction was completed, it was cooled to room temperature, filtered, washed with deionized water until neutral, and vacuum-dried at 70° C. for 12 h to obtain an intermediate product.

[0037] (2) The intermediate product and 3.053g 10-(2,5-dihydroxyphenyl)-9,10-dihydro-9-oxa-10-phosphinephenanthrene-10-oxide (DOPO-HQ) were added to Stir and reflux in 300mL tetrahydrofuran solution in an oil bath at 85°C for 12h, then cool the resulting precipitate to room temperature, filter, and dry to obtain a functionalized graphene flame retardant (FGO-HQ).

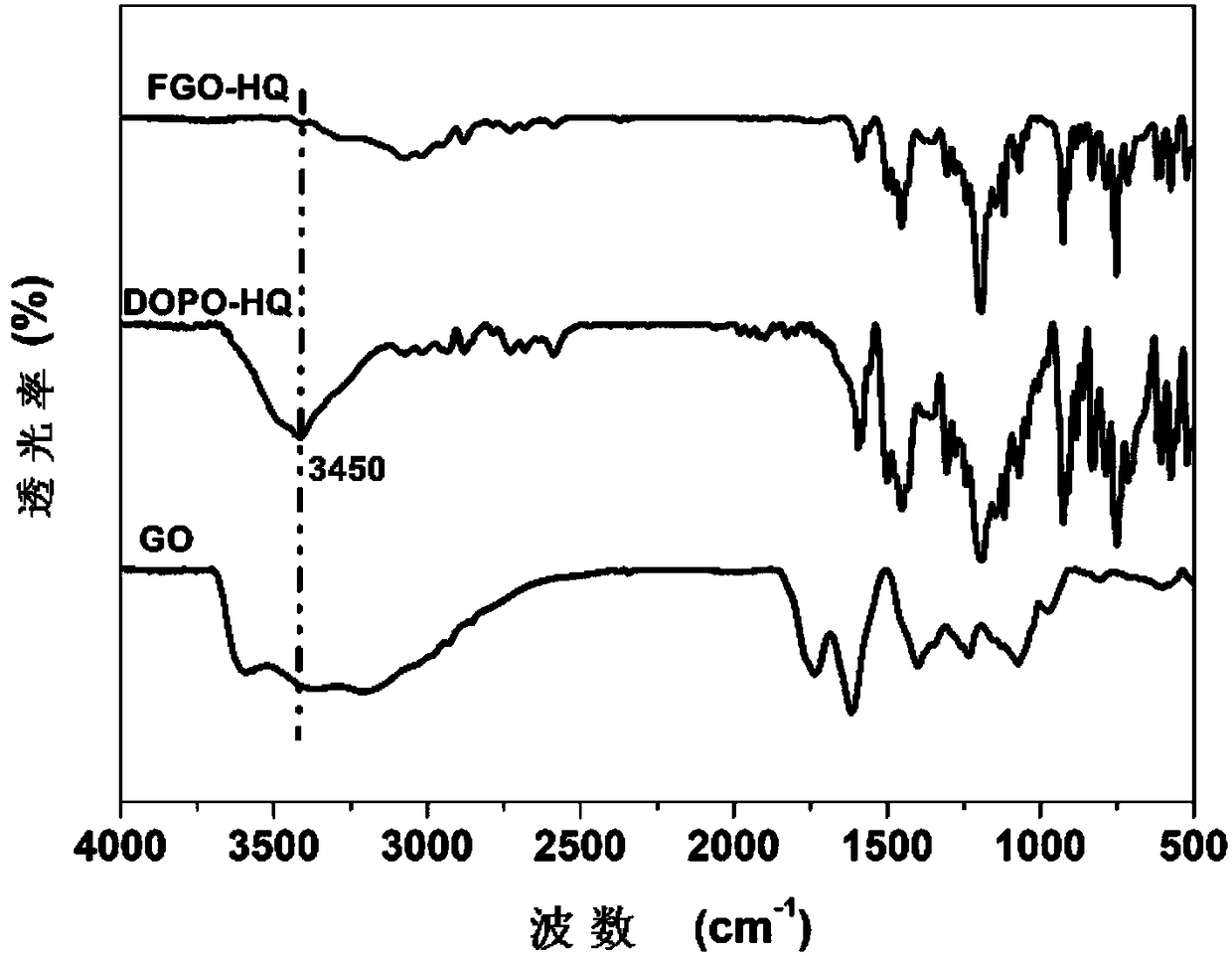

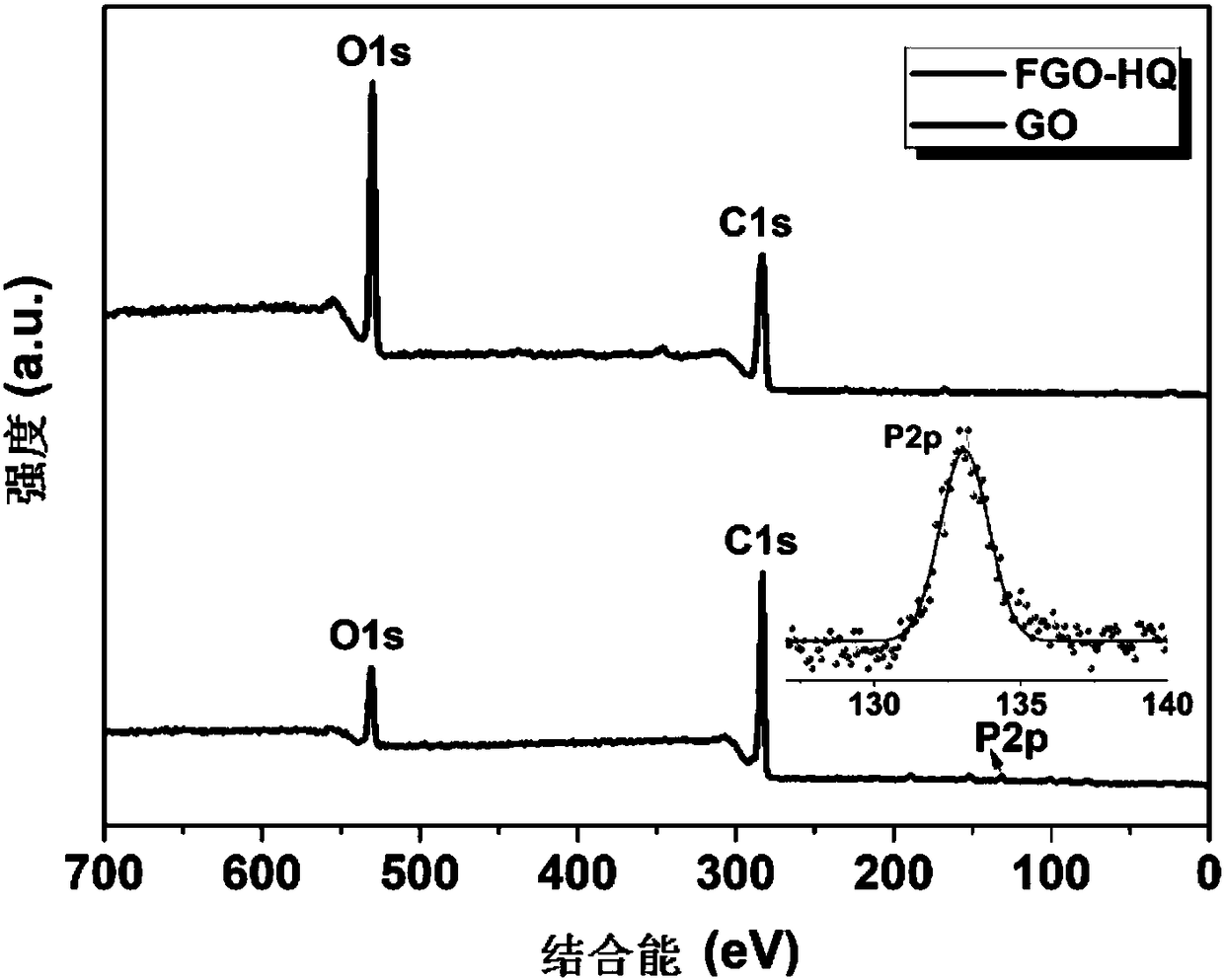

[0038] The infrared spectrogram of the functionalized graphene flame retardant prepared by the present embodiment is as follows figure 2 shown. Fr...

Embodiment 3

[0041] The functionalized graphene flame retardant prepared in Example 2 and polylactic acid are added into the internal mixer according to 2:98 (mass ratio) at 180°C for melt blending for 10min, and after mixing evenly, the mixture is heated at a temperature of 200°C and a pressure of 120×120×3.0mm obtained by hot pressing under the condition of 15MPa 3 and 100×100×1.0mm 3 polylactic acid composite sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com