Curve surface glass shaping device and shaping method

A curved glass and forming device technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve problems affecting the quality of curved glass forming and difficult control of temperature field, so as to improve yield and process efficiency, The heating and cooling is convenient and easy, and the effect of avoiding mold marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

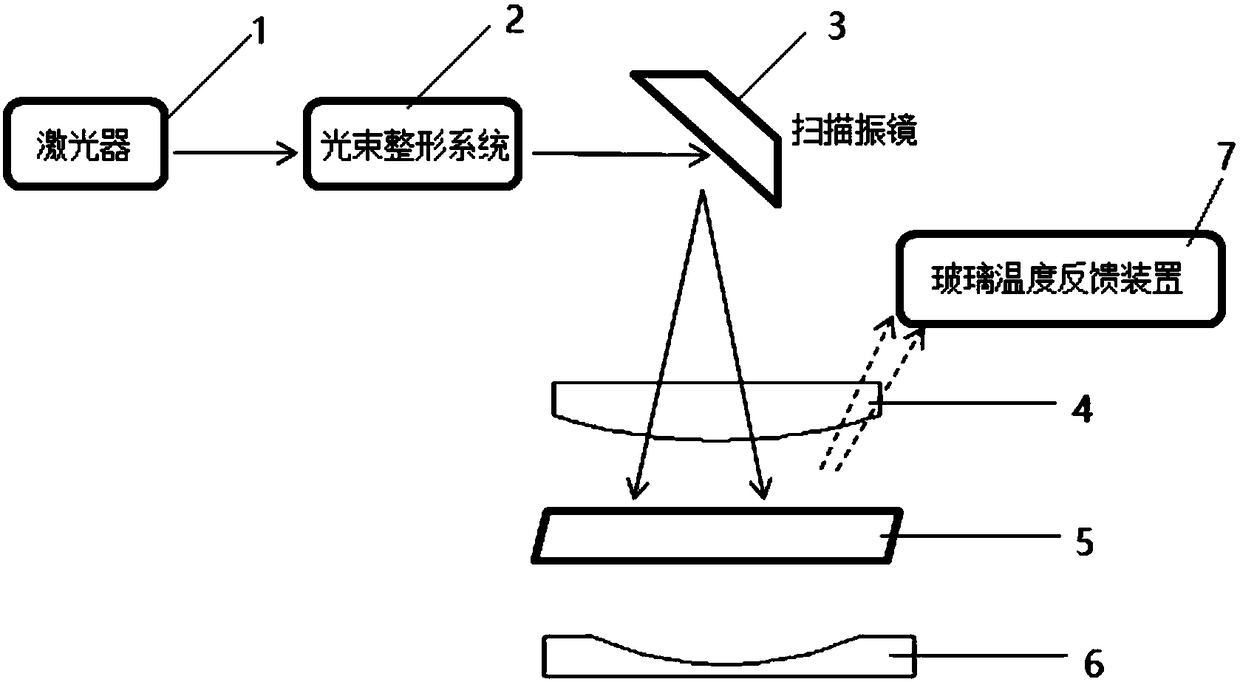

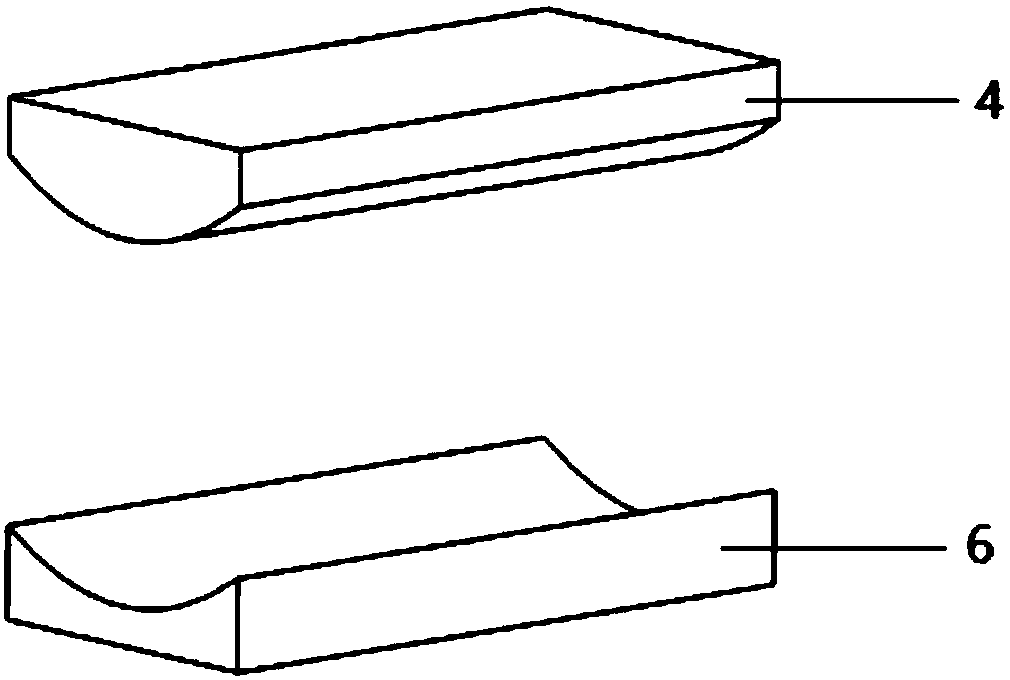

[0050] like figure 1 As shown, a curved glass forming device includes:

[0051] Laser (including laser control) system, beam shaping system, scanning galvanometer, upper and lower curved surface forming molds, glass temperature feedback device;

[0052] Laser control is connected with the laser, mainly controlling laser power, laser switching and adjusting process parameters, etc.;

[0053] For the above lasers, choose CO with a laser wavelength of 10.6 μm 2 laser;

[0054] The above-mentioned beam shaping system may include a beam expanding lens or a shaping lens group to expand and collimate the laser beam or shape the spot into a circle, ellipse, square, rectangle or other shapes;

[0055] The above-mentioned light spot shaped by the beam shaping system can be circular, square, rectangular or other shapes, preferably a rectangular light spot;

[0056] The above-mentioned scanning galvanometer is also called a laser galvanometer, which is composed of an X-axis or Y-axis ...

Embodiment 2

[0071] The structure is the same as that of Example 1. In Example 2, the scanning galvanometer is adjusted to the bottom, that is, the laser beam is irradiated from bottom to top, and the laser beam passes through the lower mold to heat and soften the glass. Other process flow is identical with embodiment 1. The principle and structure of the specific implementation are as follows: Figure 5 shown.

[0072] As can be seen from the above, the present invention has the following advantages:

[0073] 1. Compared with the traditional scheme, the present invention uses laser beam irradiation to heat and soften the glass, which has many advantages such as adjustable heating rate, high efficiency, energy saving, and controllable heat distribution.

[0074] 2. The glass temperature feedback device monitors and feedbacks the temperature, and the heating temperature has high precision, so as to avoid glass cracking caused by uneven heating.

[0075] 3. Germanium glass is used as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com