Preparation method of surface organic modified titanium carbide nanosheet

A titanium carbide and nanosheet technology is applied in the field of preparation of surface organically modified titanium carbide nanosheets. Market application prospects, large specific surface area, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Take 0.5g of titanium aluminum carbide and 0.5g of lithium fluoride in a plastic beaker, add 10mL of hydrochloric acid with a concentration of 9mol / L, stir and react at 40°C for 48h at a stirring speed of 400rpm, and centrifuge and wash repeatedly after the reaction When the pH is 7, titanium carbide precipitates are obtained after drying.

[0027] 2) Take 0.2 g of the precipitated titanium carbide obtained in step 1), disperse it in 50 mL of deionized water, ultrasonicate for 40 min at 2° C. with an ultrasonic power of 200 W, then centrifuge at 4500 rpm to remove the precipitate, and take the supernatant, namely A suspension of titanium carbide nanosheets was obtained.

[0028] 3) Take 25 mL of the titanium carbide nanosheet suspension obtained in step 2), mix it with 1 mL of cetyltrimethylammonium bromide aqueous solution with a mass concentration of 5%, stir and react at 40° C. for 2 h, and the stirring speed is 400 rpm After the reaction, the product obtained af...

Embodiment 2

[0035] 1) Take 0.5g of titanium aluminum carbide and 0.5g of lithium fluoride in a plastic beaker, add 10mL of hydrochloric acid with a concentration of 10mol / L, stir and react at 30°C for 60h at a stirring speed of 500rpm, and centrifuge and wash repeatedly after the reaction When the pH is 6.5, titanium carbide precipitates are obtained after drying.

[0036] 2) Take 0.2 g of the precipitated titanium carbide obtained in step 1), disperse it in 40 mL of deionized water, ultrasonicate for 30 min at 0° C. with an ultrasonic power of 300 W, then centrifuge at 4000 rpm to remove the precipitate, and take the supernatant, namely A suspension of titanium carbide nanosheets was obtained.

[0037] 3) Take 25 mL of the titanium carbide nanosheet suspension obtained in step 2), mix it with 2 mL of dodecyltriphenylphosphine bromide aqueous solution with a mass concentration of 2%, stir and react at 35° C. for 3 h, and the stirring speed is 500 rpm After the reaction, the product obtai...

Embodiment 3

[0039]1) Take 0.5g of titanium aluminum carbide and 0.5g of lithium fluoride in a plastic beaker, add 15mL of hydrochloric acid with a concentration of 8mol / L, stir and react at 50°C for 36h at a stirring speed of 600rpm, and centrifuge and wash repeatedly after the reaction When the pH is 6, titanium carbide precipitates are obtained after drying.

[0040] 2) Take 0.2 g of the precipitated titanium carbide obtained in step 1), disperse it in 60 mL of deionized water, ultrasonicate at 5°C for 50 min, and the ultrasonic power is 100 W, then centrifuge at 5000 rpm to remove the precipitate, and take the supernatant, namely A suspension of titanium carbide nanosheets was obtained.

[0041] 3) Take 25mL of the titanium carbide nanosheet suspension obtained in step 2), mix it with 2.5mL of dodecyltrimethylammonium chloride aqueous solution with a mass concentration of 3%, stir and react at 30°C for 4h, and the stirring speed is 600rpm, after the reaction, the product obtained afte...

PUM

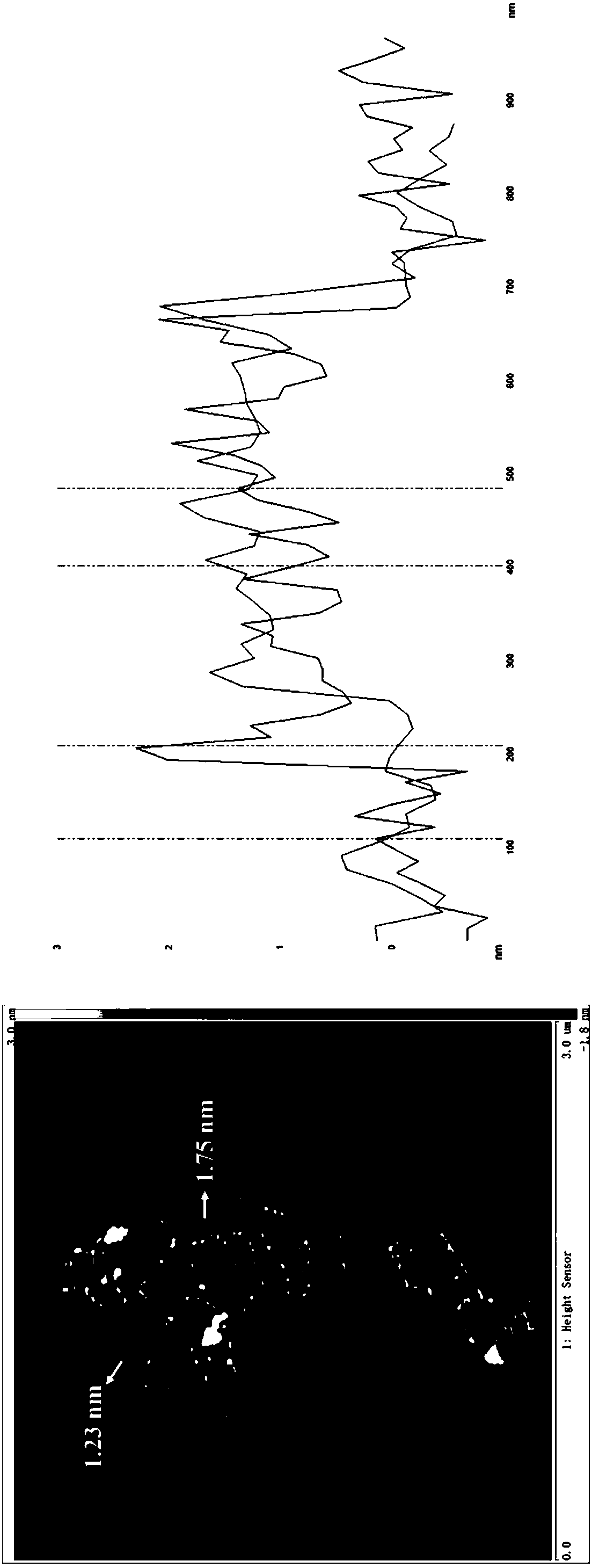

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com