Graphene preparation method

A graphene and plasma technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inability to produce in large quantities and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

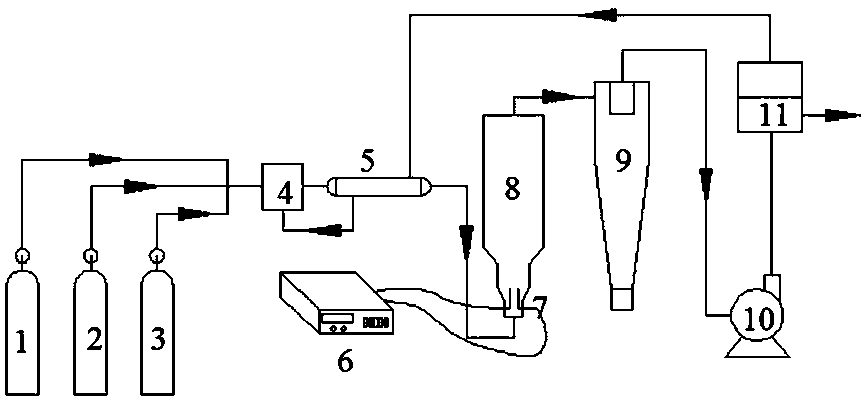

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one: a kind of method that takes methane as carbon source to produce graphene: select methane as carbon source, argon as carrier gas, hydrogen as additive; methane, argon and hydrogen with the flow ratio of 1:10:1 (volume than) into the buffer tank, and after being preheated by the heat exchanger, it is passed into the plasma generator in the form of rotating air intake; the discharge voltage of the plasma generator is 10 kV, and the current is 0.8 A; the gas in the plasma The residence time in the device in which the solid generator is combined with the fluidized bed is 10 s, and the temperature of the reactor is 1000-2700 °C; among them, the plasma generator is combined with the fluidized bed through a flare, and the diameter of the fluidized bed is plasma 4 times that of the generator nozzle; the reacted gas-solid mixture is separated from graphene by a cyclone separator, and the tail gas can be recycled to preheat the mixed gas of methane, hydrogen and arg...

Embodiment 2

[0036] Embodiment two: a kind of method of producing graphene with petroleum liquefied gas as carbon source: select petroleum liquefied gas as carbon source, nitrogen as carrier gas, ammonia as additive; petroleum liquefied gas, nitrogen and ammonia with 1:13: The flow ratio (volume ratio) of 0.8 is passed into the buffer tank, and after being preheated by the heat exchanger, it is passed into the plasma generator in the form of rotating air intake; the discharge voltage of the plasma generator is 45 kV, and the current is 0.5 A; the residence time of the gas in the plasma generator combined with the fluidized bed is 5s, and the temperature of the reactor is 2000-5700 ℃; among them, the plasma generator is combined with the fluidized bed through a flare, and the fluidized The diameter of the bed is twice that of the nozzle of the plasma generator; the gas-solid mixture after the reaction is separated from the graphene by the cyclone separator, and the tail gas can be circulated...

Embodiment 3

[0037] Embodiment three: a kind of method that uses coke oven gas as carbon source to produce graphene: select coke oven gas as carbon source, hydrogen as carrier gas and additive; coke oven gas and hydrogen with the flow ratio (volume ratio) of 1:15 It is passed into the buffer tank, and after being preheated by the heat exchanger, it is passed into the plasma generator in the form of rotating air intake; the discharge voltage of the plasma generator is 2 kV, and the current is 1 A; the gas is generated in the plasma The residence time in the device combined with the fluidized bed is 8s, and the temperature of the reactor is 2600-5300 ° C; wherein, the plasma generator is combined with the fluidized bed through a flare, and the diameter of the fluidized bed is the plasma generator nozzle 5 times of that; the reacted gas-solid phase mixture is separated from graphene through a cyclone separator, and the tail gas can be circulated to preheat the mixed gas of coke oven gas and hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com