Wire cutting force testing method and device

A testing device and cutting force technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of recording cutting force values, unsustainable, and inability to accurately monitor the stability of wire materials, etc., to ensure Turning accuracy, improve turning accuracy, and ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

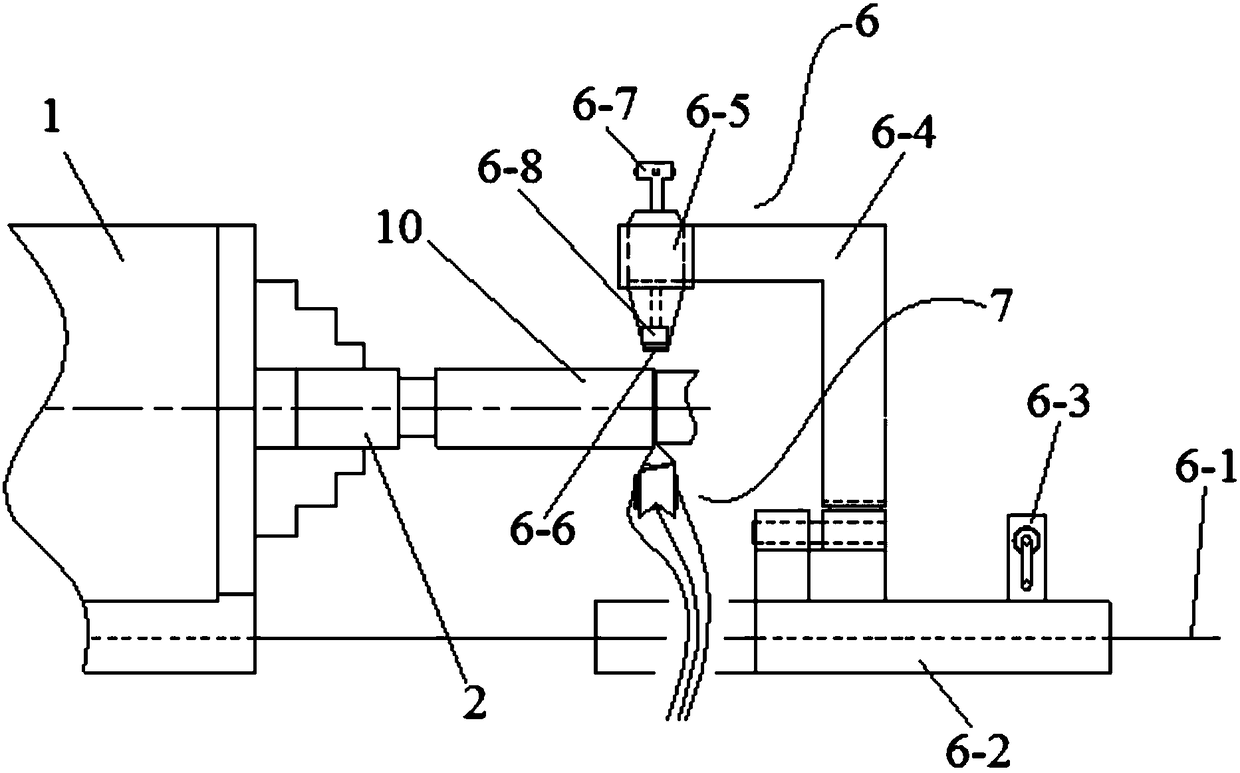

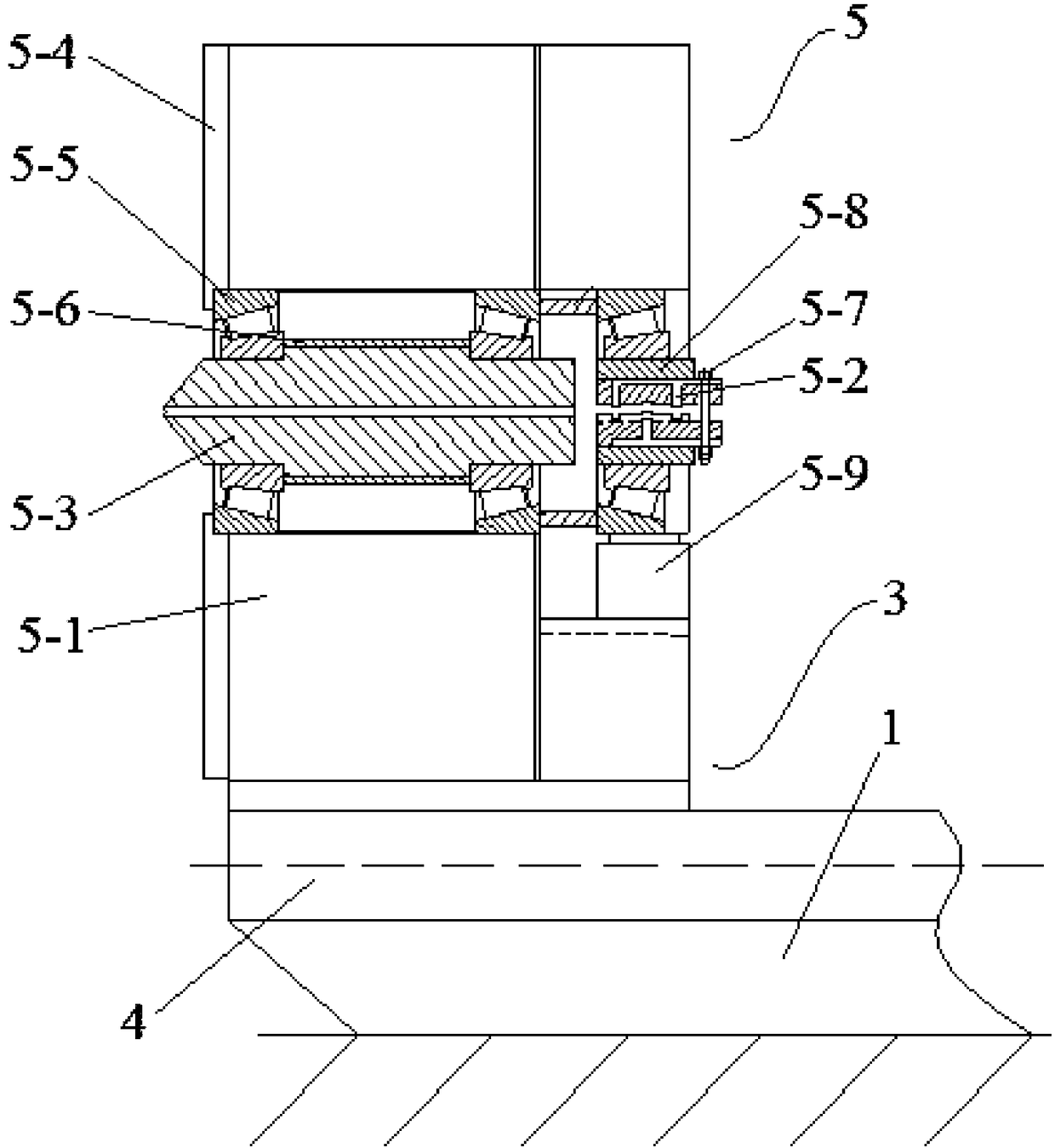

[0040] The present embodiment provides a kind of testing device of wire material cutting force, as Figure 1 to Figure 7 As shown, it includes a lathe body 1, a spindle chuck chuck 2 and a pull-type tailstock 3. The spindle chuck chuck 2 is installed on the lathe body 1, and the pull-type tailstock 3 is installed on the guide rail 4. Above, the guide rail 4 is installed on the lathe body 1, and the wire clamping assembly 5 is installed on the pull-type tailstock 3, and the wire clamping assembly 5 includes a tailstock installed on the pull-type tailstock 3 Tube 5-1, the said tailstock tube 5-1 is equipped with a wire material clamping head 5-2, a hollow mandrel 5-3 and a tailstock cover plate 5-4, and said hollow mandrel 5- 3 Rotate and install in the tailstock barrel 5-1 through the bearing 5-5, the hollow mandrel is also sleeved with a mandrel sleeve 5-6, and the wire clamping head 5-2 A clamping head screw 5-7 and a fixing splint 5-8 for fixing and clamping the wire are al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com