High-temperature lead-free solder wire and preparation method thereof

A lead-free soldering and high-temperature technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of low melting point of solder wire, reduce water absorption efficiency, reduce the probability of mildew, and reduce the effect of splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

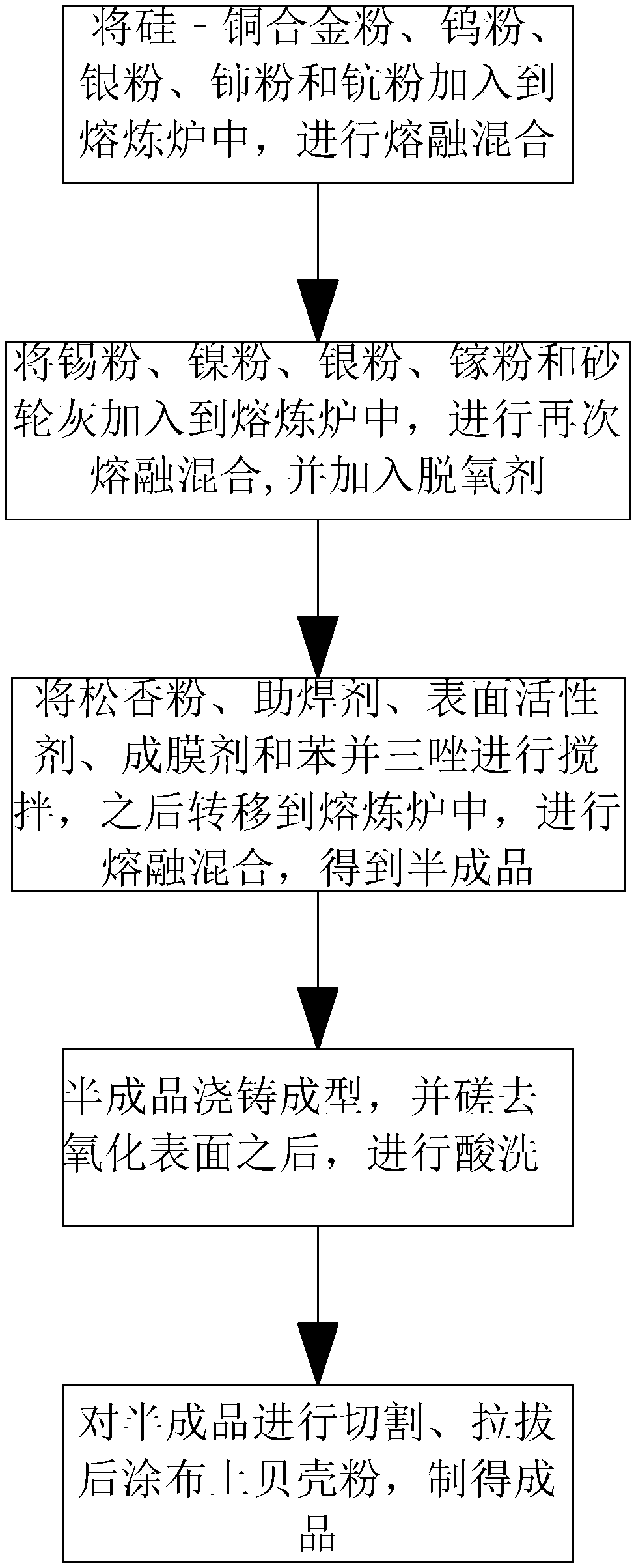

[0039] A preparation method of high-temperature lead-free solder wire, comprising the following steps:

[0040] Step 1: Add 20Kg of silicon-copper alloy powder, 10Kg of tungsten powder, 2Kg of silver powder, 1Kg of cerium powder and 3Kg of scandium powder into the melting furnace for melting and mixing;

[0041] Step 2: Add 120Kg tin powder, 12Kg nickel powder, 2Kg indium powder, 3Kg gallium powder and 15Kg grinding wheel dust into the melting furnace of S1, melt and mix again, and add deoxidizer for deoxidation treatment;

[0042] Step 3: 14Kg rosin powder, 1Kg soldering flux, 2Kg surfactant, 0.2Kg film forming agent and 0.5Kg benzotriazole are added in the agitator and stirred, then transferred to the smelting furnace of step 2 and mixed to obtain semi-finished products;

[0043] Step 4: Cast the semi-finished product into a mold to form it, use a lathe to remove the oxidized surface of the semi-finished product, and then use strong acid to pickle the semi-finished product;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com