A four-steel steel-constrained segmental buckling-resistant brace with replaceable cross-shaped inner core

A buckling-resistant support, cross-shaped technology, applied in the direction of earthquake resistance, building types, protected buildings/shelters, etc., can solve problems such as irreparable, meet the needs of functional restoration, reduce costs, improve efficacy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

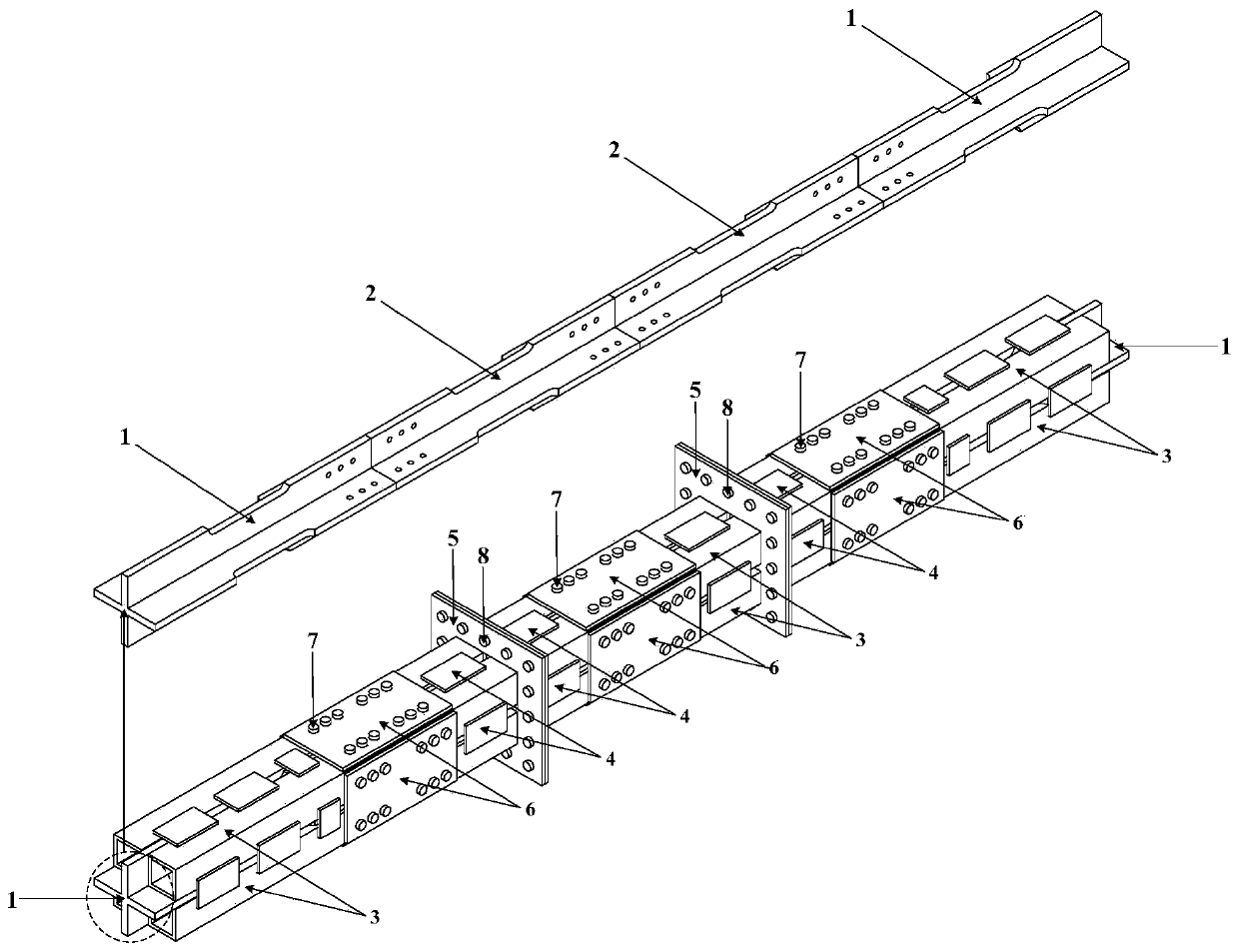

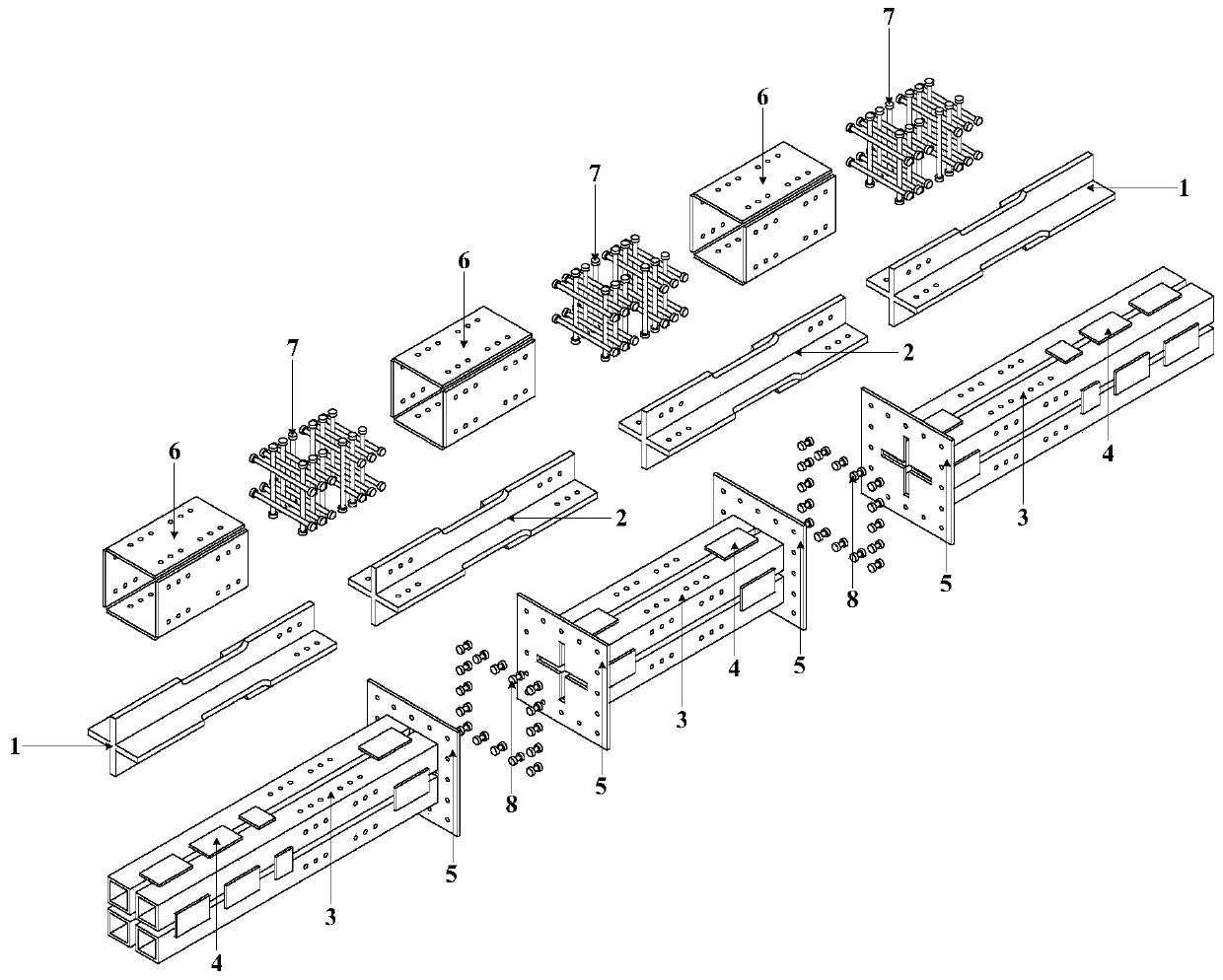

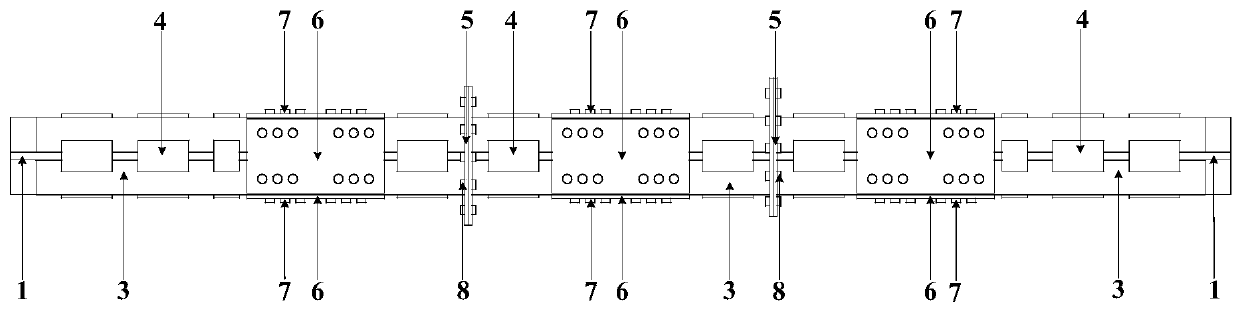

[0029] Attached below Figure 1-8 , detailing the implementation of this patent.

[0030] Such as Figure 1-8 As shown, a four-steel steel restraint segmental buckling support with replaceable cross-shaped inner core includes the following components:

[0031] 1——Side section cross-shaped core member;

[0032] 2——the cross-shaped inner core component in the middle section;

[0033] 3—Steel steel restraint member;

[0034] 4 - embossed board;

[0035] 5 - flange;

[0036] 6——connection cover outside the inner core;

[0037] 7——The first high-strength bolt group;

[0038] 8——The second high-strength bolt group;

[0039] 9——side peripheral restraint device unit;

[0040] 10—the peripheral restraint device unit of the middle section;

[0041] 11——The end reinforcement area of the cross-shaped core member of the side section;

[0042] 12——The central weakened area of the cross-shaped inner core member of the side section;

[0043] 13——The opening connection area at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com