Preparation method of high-strength medium-manganese steel plate

A manganese steel plate, high-strength technology, applied in the field of preparation of high-strength medium-manganese steel plate, can solve the problems of stamping and forming of automobile plates, surface wrinkles of steel parts, no macro work hardening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Smelting and forging: 1# steel is smelted in a vacuum induction furnace, and its composition is shown in Table 1. The obtained molten steel is cast and forged to obtain a billet of 60mm×60mm×300mm.

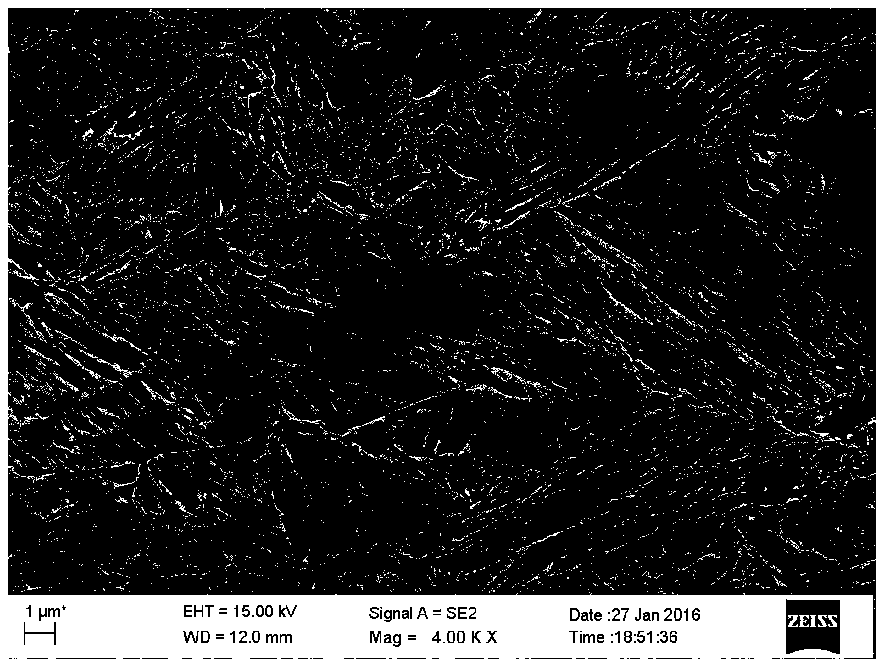

[0065] (2) Hot rolling: heat the cast slab to 1150°C for 3 hours, start rolling at 1000°C, go through 7 passes of hot rolling, and finish at 800°C, with a total cumulative reduction of 96%, single pass The reduction ratio was 30%. Air-cool to room temperature after hot-rolling, and the thickness of the hot-rolled sheet is 2.5mm. Such as figure 1 As shown, the hot-rolled microstructure is dominated by lath martensite.

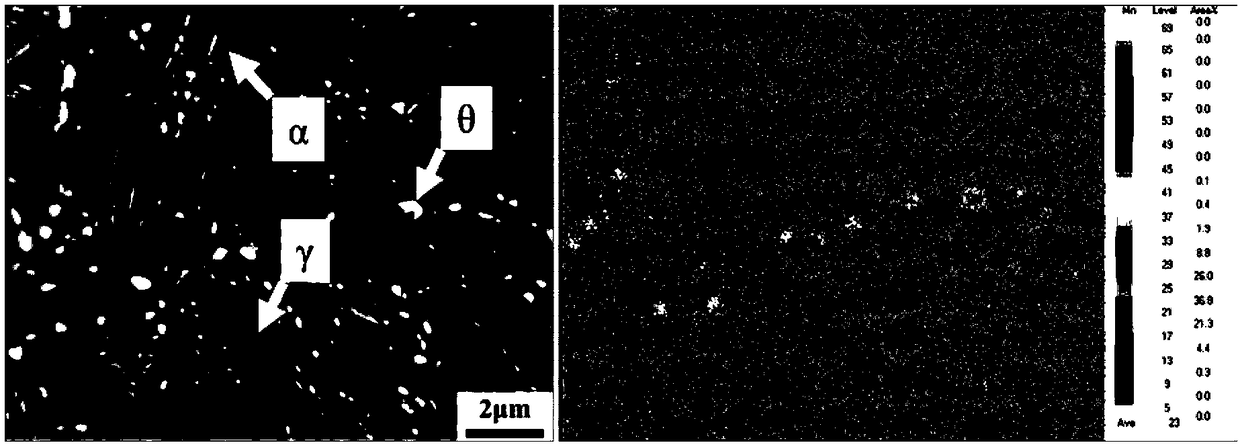

[0066] (3) Primary annealing: put the hot-rolled sheet into a box furnace at 620°C for 10 hours to simulate bell annealing, and air-cool to room temperature. figure 2 It is the SEM image of 1# steel annealed at 620°C for 10h and the surface scan image of the corresponding Mn element; the structure is lath ferrite and austenite, and there is cementite ...

Embodiment 2

[0073] (1) Smelting and forging: 2# steel was smelted in a vacuum induction furnace. The composition is shown in Table 1. The obtained molten steel was cast and forged to obtain a billet of 60mm×60mm×300mm.

[0074] (2) Hot rolling: heat the cast slab to 1200°C for 2 hours, start rolling at 1050°C, after 6 passes of hot rolling, finish rolling at 820°C, the total cumulative reduction is 96%, single pass The reduction ratio was 30%. Air cooling to 600°C after hot rolling, then furnace cooling, simulated coiling, the thickness of the hot rolled sheet is 2.4mm.

[0075] (3) Primary annealing: put the hot-rolled sheet into a box furnace at 650°C for 24 hours to simulate bell annealing, and air-cool to room temperature.

[0076] (4) Cold rolling: the above-mentioned annealed steel plate is cold-rolled, and the total cold-rolling reduction is 0% (no cold-rolling), 10%, and 15% respectively to obtain a cold-rolled plate. The cold-rolling reduction of the comparison process The amou...

Embodiment 3

[0082] (1) Smelting and forging: 3# steel was smelted in a vacuum induction furnace. The composition is shown in Table 1. The obtained molten steel was cast and forged to obtain a billet of 60mm×60mm×300mm.

[0083] (2) Hot rolling: heat the cast slab to 1250°C for 4 hours, start rolling at 1050°C, after 7 passes of hot rolling, finish at 780°C, total cumulative reduction is 95%, single pass The reduction ratio was 30%. Air-cool to room temperature after hot-rolling, and the thickness of the hot-rolled sheet is 3.1mm.

[0084] (3) Primary annealing: put the hot-rolled sheet into a box furnace at 600°C for 36 hours, simulate bell annealing, and air-cool to room temperature.

[0085](4) Cold rolling: the above-mentioned annealed steel plate is cold-rolled, and the total cold-rolling reduction is respectively 0% (no cold-rolling), 10%, and 18%, to obtain a cold-rolled plate, and the cold-rolling reduction of the comparison process The amounts are 40% and 50%.

[0086] (5) Seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com