High-low-temperature-resistance high-ductility cable material and preparation method thereof

A technology with high and low temperature resistance and ductility, applied in plastic/resin/wax insulators, organic insulators, etc. The effect of poor high and low temperature resistance, long flexural life and strict proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

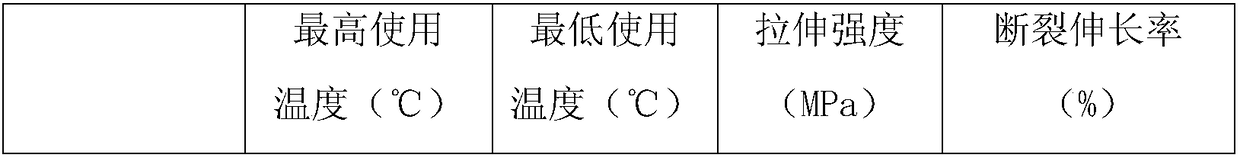

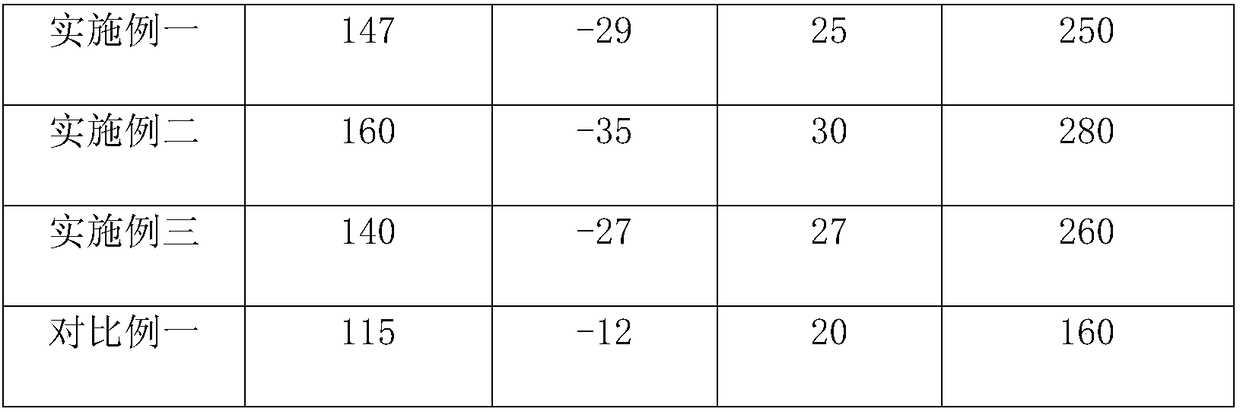

Examples

Embodiment 1

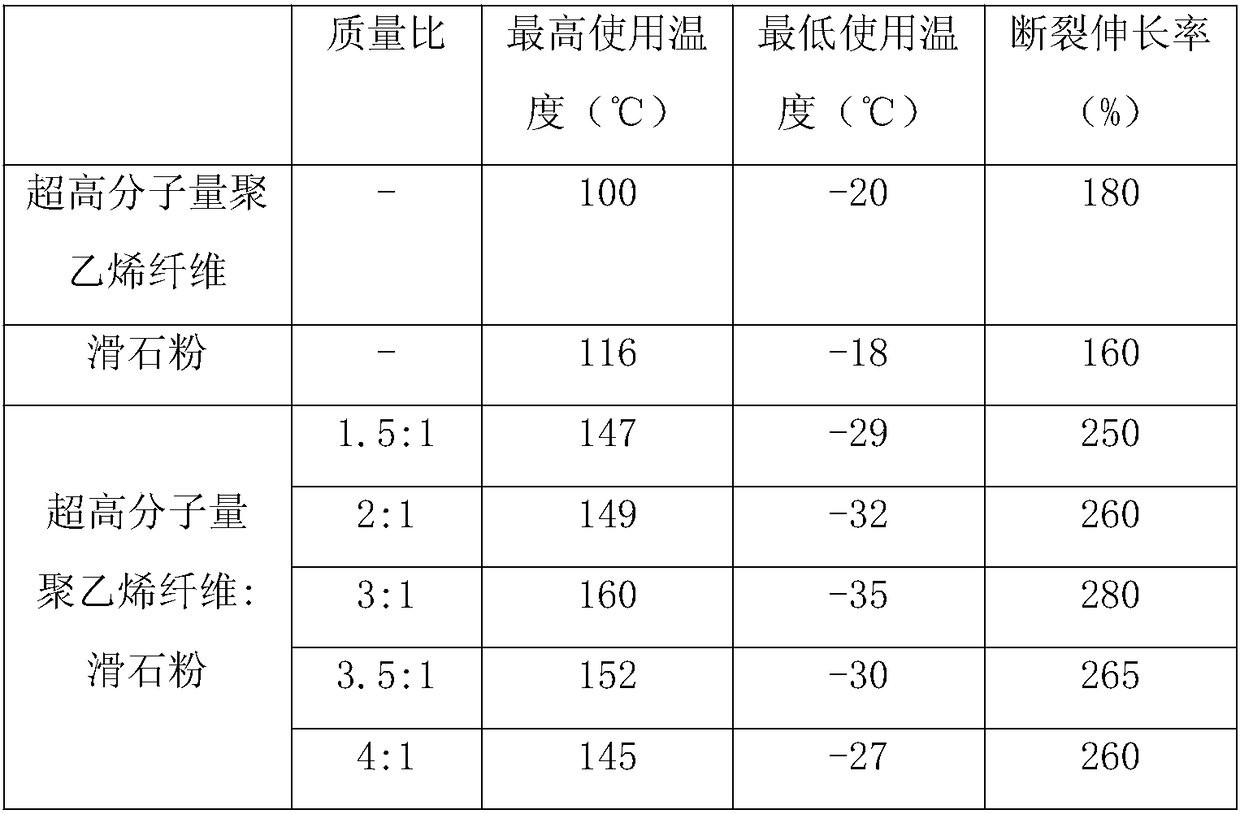

[0017] A high-low temperature resistance and high ductility cable material proposed by the present invention includes the following raw materials in parts by weight: 20 parts of epoxy resin, 15 parts of ABS resin, 3 parts of ultra-high molecular weight polyethylene fiber, 2 parts of talcum powder, ethylene- 15 parts of vinyl acetate, 1.4 parts of antioxidant, and 3 parts of flame retardant; wherein, the flame retardant is a compound of phosphorus nitrogen series halogen-free flame retardant and inorganic flame retardant.

[0018] Its preparation method comprises the following steps:

[0019] S1. Add the talcum powder and ultra-high molecular weight polyethylene fiber of the specific gravity into the grinder, grind it thoroughly for 20 minutes, then add it to the ultrasonic oscillator, add water 0.5 times the total amount of the ground material, shake for 5 minutes, and dehydrate and dry Mixture A is obtained;

[0020] S2. Add epoxy resin and ABS resin to the resin softening t...

Embodiment 2

[0023] A high-low temperature resistance and high ductility cable material proposed by the present invention comprises the following raw materials in parts by weight: 35 parts of epoxy resin, 28 parts of ABS resin, 7 parts of ultra-high molecular weight polyethylene fiber, 3 parts of talcum powder, ethylene- 20 parts of vinyl acetate, 1.7 parts of antioxidant, and 3.6 parts of flame retardant; wherein, the flame retardant is a compound of phosphorus-based halogen-free flame retardant and inorganic flame retardant.

[0024] Its preparation method comprises the following steps:

[0025] S1. Add the talc powder and ultra-high molecular weight polyethylene fiber of the specific gravity into the grinder, grind it thoroughly for 25 minutes, then add it to the ultrasonic oscillator, add water 0.8 times the total amount of the ground material, shake for 7 minutes, and dehydrate and dry Mixture A is obtained;

[0026] S2. Add epoxy resin and ABS resin to the resin softening tank, heat...

Embodiment 3

[0029] A high-low temperature resistance and high ductility cable material proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of epoxy resin, 40 parts of ABS resin, 16 parts of ultra-high molecular weight polyethylene fiber, 4 parts of talcum powder, ethylene- 25 parts of vinyl acetate, 1.9 parts of antioxidant, and 5 parts of flame retardant; wherein, the flame retardant is a phosphorus-nitrogen series halogen-free flame retardant.

[0030] Its preparation method comprises the following steps:

[0031] S1. Add the talc powder and ultra-high molecular weight polyethylene fiber of the specific gravity into the grinder, grind it thoroughly for 30 minutes, then add it to the ultrasonic oscillator, add water 1.2 times the total amount of the ground material, shake for 10 minutes, and dehydrate and dry Mixture A is obtained;

[0032] S2. Add epoxy resin and ABS resin to the resin softening tank, heat at 100°C for 3 hours, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com