Halogen-free high-efficiency flame-retardant cationic emulsion modified in-situ by nanomaterials and preparation method thereof

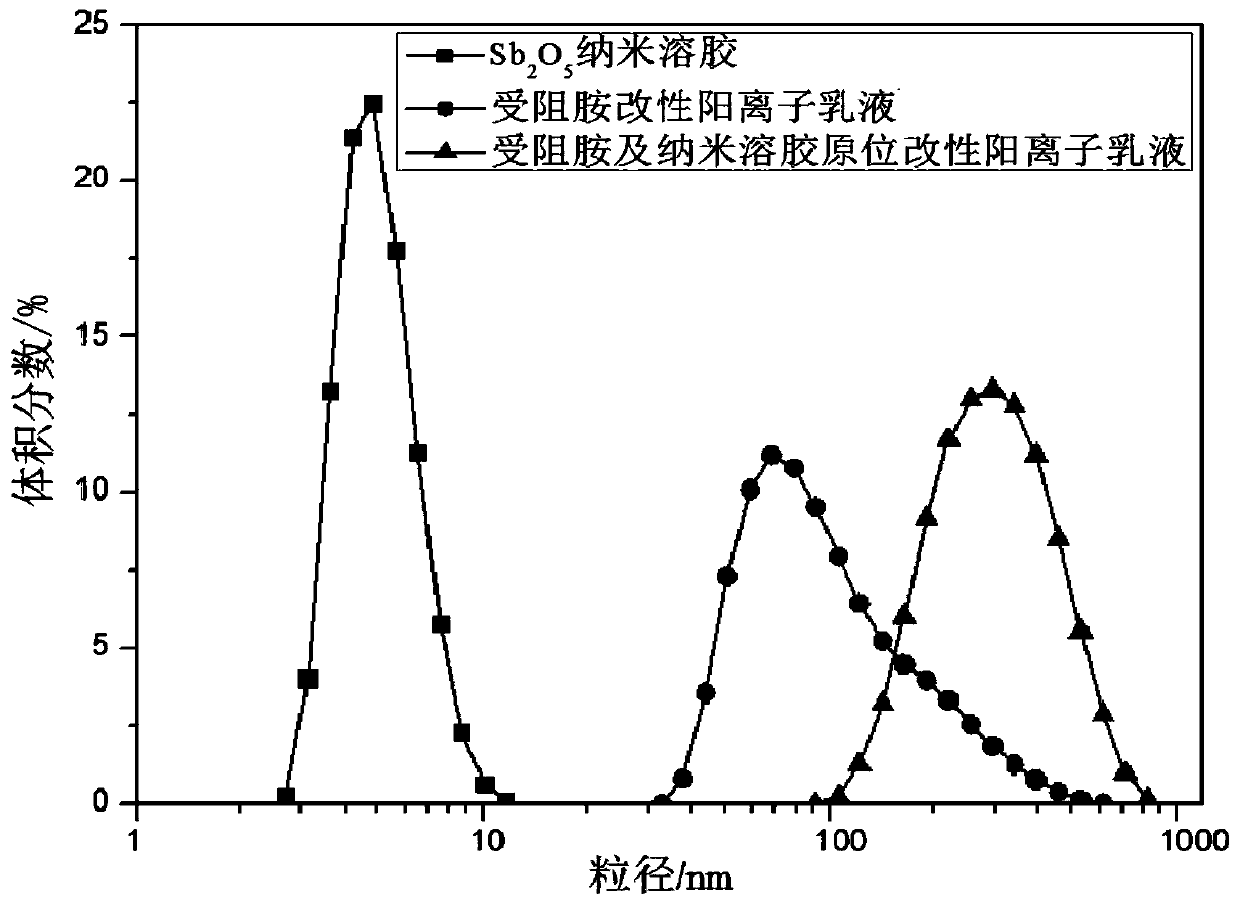

A cationic emulsion and in-situ modification technology, which is applied in the field of halogen-free high-efficiency flame-retardant cationic emulsion and its preparation in-situ modified by nano-materials, can solve the problem of unsatisfactory flame-retardant effect of halogen-free flame retardants and affect polymer water resistance Performance, it is difficult to meet the requirements of B1 grade flame retardant materials, etc., to achieve high reaction conversion rate and efficient flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1). Preparation of cationic seed emulsion

[0068] The seed emulsion proportioning is as follows (parts by weight):

[0069]

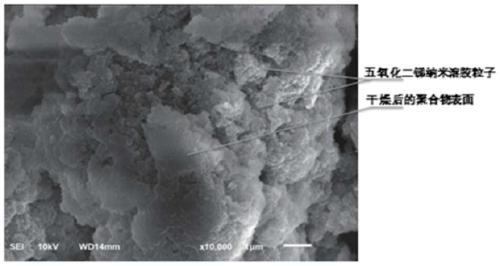

[0070] Add primer water in the reaction kettle, add dispersant (mass concentration is 25% cationic starch dispersion liquid), emulsifier, antimony sol (mass concentration is 18% antimony pentoxide nano-sol), azobis For isobutyramide hydrochloride, after vacuum degassing, pass nitrogen to catch oxygen and raise the temperature, add the primer monomer dropwise at 70°C, and keep it warm for 30 minutes after the dripping, the preparation of the primer seed emulsion is completed.

[0071] 2). Preparation of pre-emulsion

[0072] Pre-emulsion a ratio:

[0073]

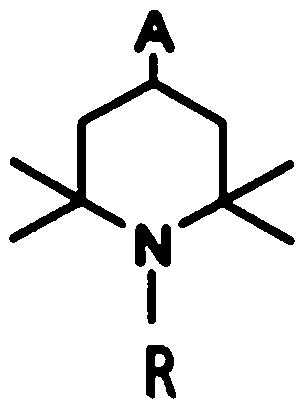

[0074] Prepare the pre-emulsion at the same time as the primer. First, dissolve the hindered amine radical scavenger in the polymerized monomer MMA according to the proportion of the pre-emulsion b; then dissolve the emulsifier, dispersant, and initiator in the pre-emulsion water acco...

Embodiment 2

[0081] 1). Preparation of cationic seed emulsion

[0082] Seed emulsion ratio:

[0083]

[0084] Add bottoming water into the reaction kettle, add starch dispersion, emulsifier, antimony pentoxide nano-sol, azobisisobutylamidine hydrochloride during stirring, and vacuum degassing, then pass nitrogen to catch oxygen and heat up, at 70°C Add the primer monomer dropwise, keep warm for 30 minutes after dripping, and the preparation of the primer seed emulsion is completed.

[0085] 2). Preparation of pre-emulsion

[0086] Pre-emulsion a ratio:

[0087]

[0088] Proportion of pre-emulsion b:

[0089]

[0090] Prepare the pre-emulsion at the same time as the primer. First, dissolve the hindered amine radical scavenger in the polymerized monomers MMA and BA according to the proportion of the pre-emulsion b; then dissolve the emulsifier, dispersant, and initiator in the pre-emulsion water according to the pre-emulsion a , adding polymerized monomers to pre-emulsify to pr...

Embodiment 3

[0097] 1). Preparation of cationic seed emulsion

[0098] Seed emulsion ratio:

[0099]

[0100] Add bottoming water into the reaction kettle, add starch dispersion, emulsifier, antimony pentoxide nano-sol, azobisisobutylamidine hydrochloride during stirring, and vacuum degassing, then pass nitrogen to catch oxygen and heat up, at 70°C Add the primer monomer dropwise, keep warm for 30 minutes after dripping, and the preparation of the primer seed emulsion is completed.

[0101] 2). Preparation of pre-emulsion

[0102] Pre-emulsion a ratio:

[0103]

[0104] Proportion of pre-emulsion b:

[0105]

[0106] Prepare the pre-emulsion at the same time as the primer. First, dissolve the hindered amine radical scavenger in the polymerized monomers MMA and BA according to the proportion of the pre-emulsion b; then dissolve the emulsifier, dispersant, and initiator in the pre-emulsion water according to the pre-emulsion a , adding polymerized monomers to pre-emulsify to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com