A unidirectional traveling-wave annular 2μm single-frequency tunable solid-state laser

A solid-state laser, traveling wave technology, applied in the optical field, can solve the problems of low frequency stability, decreased output power, and degraded beam quality, and achieves the effect of simple structure, low insertion loss, and avoiding bad problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

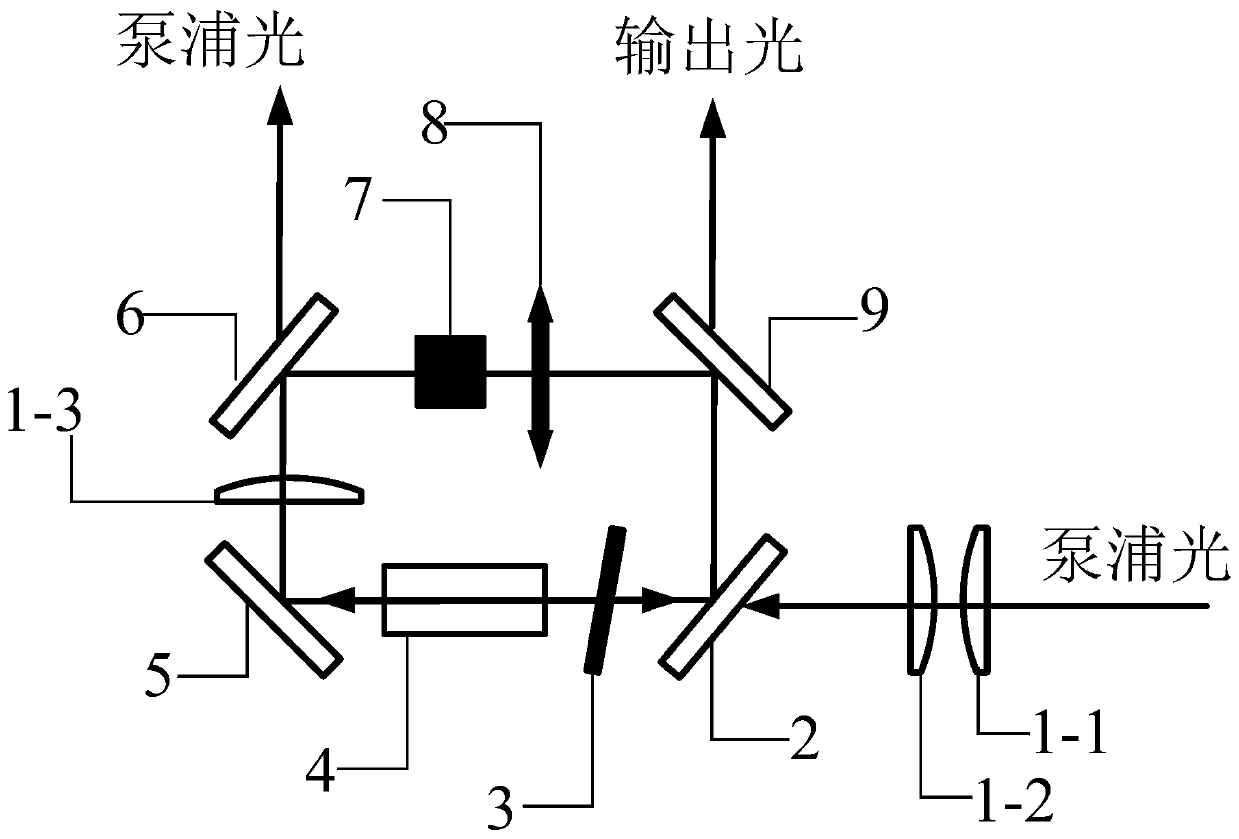

[0017] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode. In this embodiment mode, a unidirectional traveling wave annular 2 μm single-frequency tunable solid-state laser includes a first plano-convex lens 1-1, a second plano-convex lens 1-2, a third plano-convex lens 1-3, and pump light Input mirror 2, F-P etalon 3, Tm:YAG crystal 4, mirror 5, dichroic mirror 6, optical rotator 7, half-wave plate 8 and output mirror 9;

[0018] The convex surfaces of the first plano-convex lens 1-1 and the second plano-convex lens 1-2 are opposite to form a coupling system;

[0019] The 785nm pump light incident to the coupling system is coupled by the coupling system and then incident on the pump light input mirror 2 at 45°; the 785nm pump light transmitted by the pump light input mirror 2 is incident on the F-P etalon 3, and passes through the F-P etalon 3 The transmitted 785nm pump light is incident on the Tm:YAG crystal 4, and the Tm:YAG c...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the surfaces of the first plano-convex lens 1-1, the second plano-convex lens 1-2 and the third plano-convex lens 1-3 are all coated with 2 μm high-transparency The film has a focal length of 5mm to 200mm and a diameter of 1mm to 50mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the pump light input mirror 2 is coated with a high-transparency film for 785nm pump light and a high-reflection film for 2 μm oscillating light at the same time. . Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com