Polybenzimidazole proton conducting membrane with double-network structure and preparation method thereof

A polybenzimidazole, proton conductive membrane technology, applied in circuits, fuel cells, electrical components, etc., to achieve the effects of low methanol permeability/air permeability, good mechanical properties, and uniform grid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

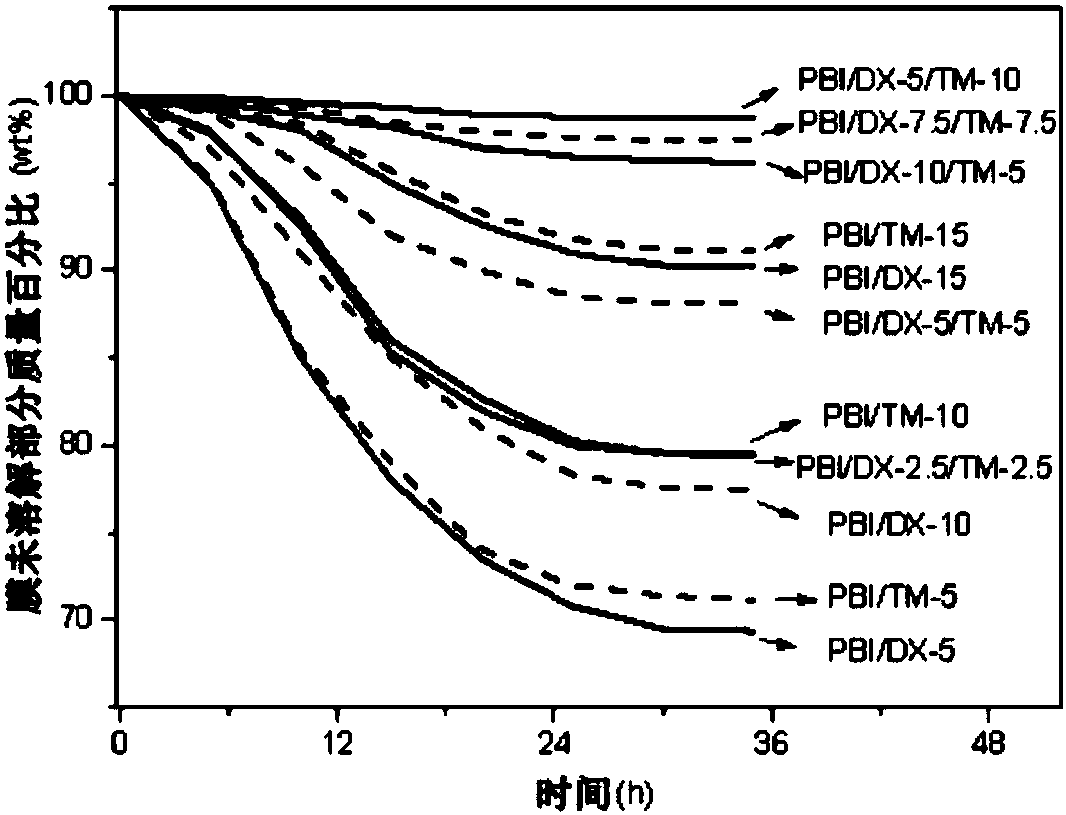

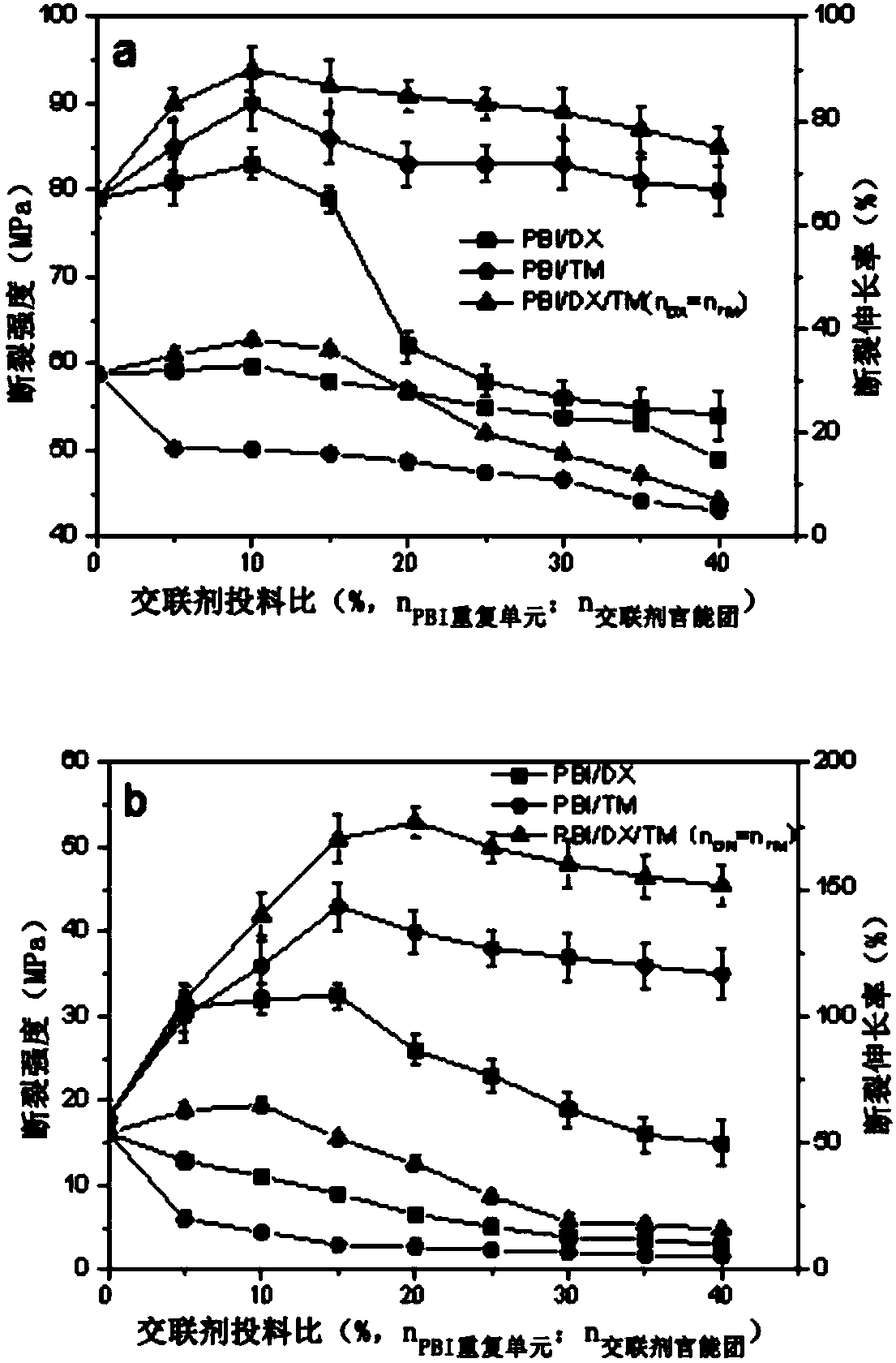

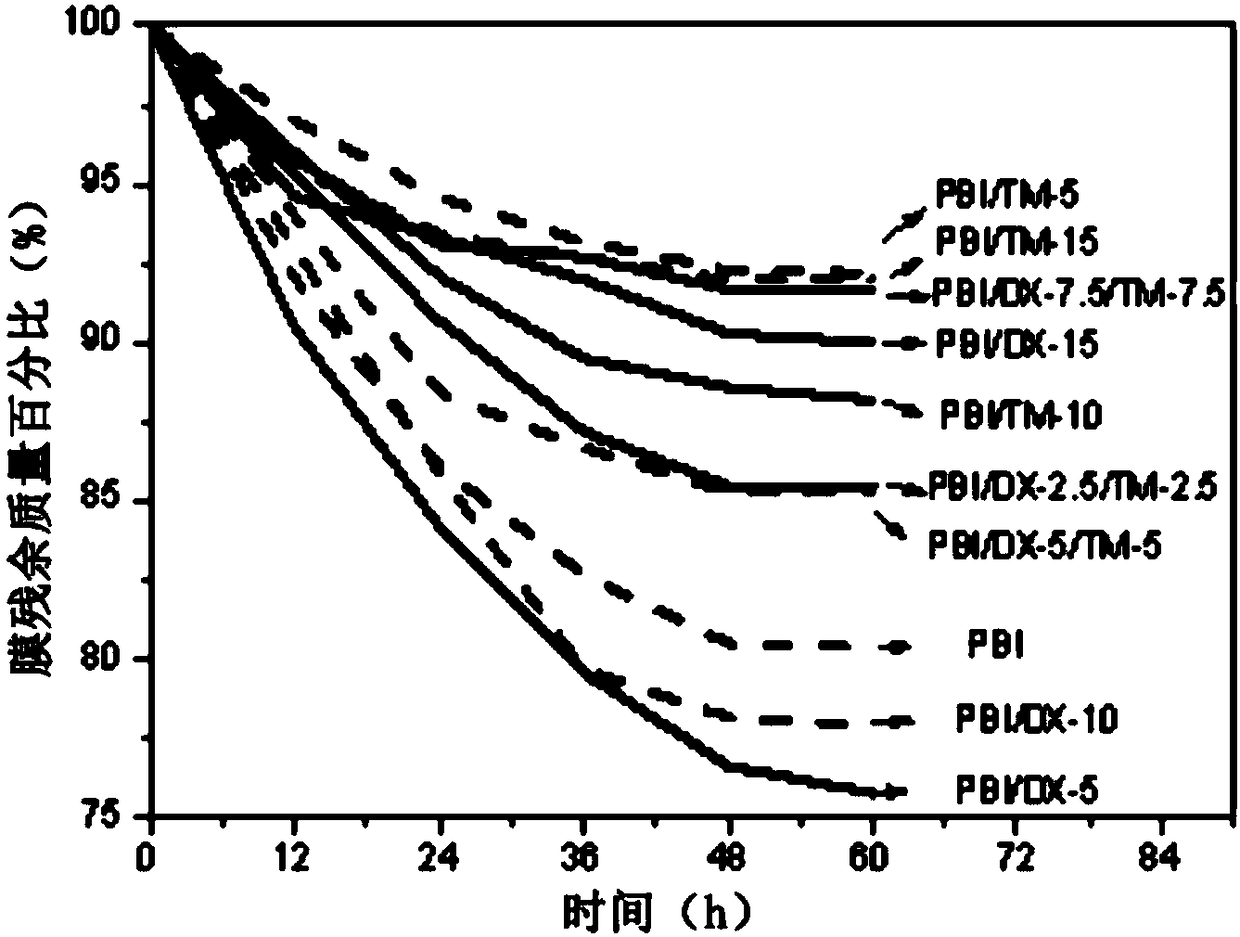

Embodiment 1

[0051] The PBI polymer is dissolved with DMAc solvent, and the dissolution is divided into two steps: 1. First, put 3.75g PBI and 150ml DMAc in a 150ml autoclave, and then magnetically stir at 220°C for 12h to obtain a gel containing part of the PBI polymer. PBI / DMAc solution; 2. Pour the above solution into a 250ml one-necked flask, reflux at 180°C for 12 hours, so that part of the undissolved PBI can be fully dissolved. The dissolved solution was filtered several times to obtain a clear brown solution which was the PBI / DMAc solution. Take three 1ml portions of the above solution on three clean glass dishes, record the mass before evaporation, and record the mass after evaporation after the DMAc solution is completely evaporated at 100°C, so as to obtain the mass concentration of the film solution. Take the above solution in a 20ml strain bottle, ensure that the solute mass is 0.4g, dilute it with DMAc solvent to a total of 20ml, add 0.0057g of p-dichlorobenzyl (DX) and 0.011...

Embodiment 2

[0065] The PBI polymer is dissolved with DMAc solvent, and the dissolution process is the same as in Example 1. Take the above solution in a 20ml strain bottle, ensure that the solute mass is 0.4g, dilute to a total amount of 20ml with DMAc solvent, add 0.0138g of 1,4-butanediol diglycidyl ether (BDE), p-dichlorobenzyl ( DX) 0.0057g of two kinds of cross-linking agents were placed in the strain bottle, and then the solution in the strain bottle was ultrasonically dispersed for 2 hours, so that the cross-linking agent could be uniformly dispersed in the solution to obtain a film solution. Pour the above membrane solution into a 10cm×10cm glass membrane frame, put the membrane frame into an oven, adjust the level of the membrane frame, and heat it at 65°C for 6 hours, and complete the cross-linking between PBI / BDE during this process. Then raise the temperature to 90° C. and keep it warm for 12 hours to complete the cross-linking between PBI / DX, thereby obtaining a double networ...

Embodiment 3

[0067] The PBI polymer is dissolved with DMAc solvent, and the dissolution process is the same as in Example 1. Take a PBI solution containing 1g of PBI solute, add 0.0814g of p-chloromethylstyrene and 0.472g of NaH, heat up to 90°C and keep it warm for 7h, use acetone to precipitate, and use dilute hydrochloric acid to wash to obtain the p-chloromethyl of PBI Styrene graft modification. The graft modified product was dissolved in DMAc at 160° C., and the dissolution method was the same as that of PBI to obtain a PBI graft modified product solution. Take the above solution in a 20ml strain bottle, ensure that the solute mass is 0.4g, dilute it with DMAc solvent to a total of 20ml, add 0.1024g of styrene (St), 0.0954g of dibenzoyl peroxide (BPO), biphenyl Bisphenol (TM) 0.0117g, two kinds of cross-linking agents were placed in the strain bottle, and the solution in the strain bottle was ultrasonically dispersed for 2 hours, so that the cross-linking agent could be uniformly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com