A kind of bonded NdFeB magnet and preparation method thereof

A neodymium iron boron and magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of low efficiency of the preparation process, and achieve the effect of improving product consistency, high density and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

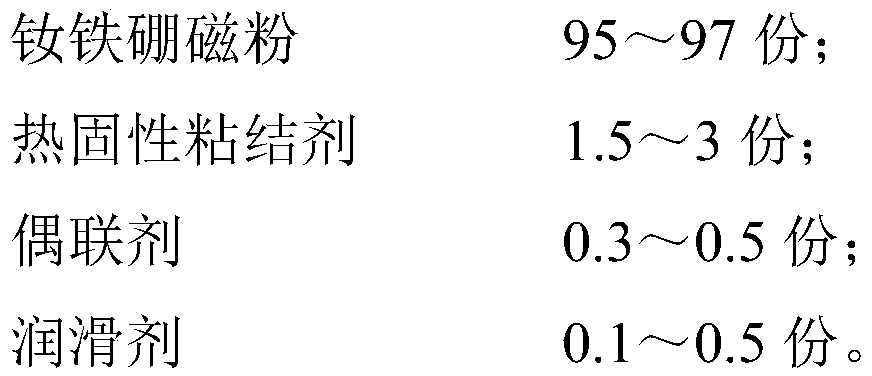

[0065] The bonded NdFeB magnet provided in this example is composed of the following components by weight:

[0066] NdFeB magnetic powder 95 parts;

[0067] 1.5 parts of thermosetting adhesive W-6C;

[0068] Silane coupling agent KH-5500.3 parts;

[0069] Zinc stearate 0.1 part.

[0070] And the particle size of the binder powder in this example is 250 mesh.

[0071] In this example, the preparation of bonded NdFeB magnets is completed through the following process:

[0072] (1) Crushing the required NdFeB magnetic powder through a 200-mesh sieve;

[0073] (2) Add 95 parts of sieved NdFeB magnetic powder and 1.5 parts of powdery thermosetting binder W-6C into the mixing equipment and stir evenly, then pass 5 parts of acetone solution with 0.2 parts of coupling agent through the mist Chemical equipment is evenly sprayed onto the surface of the mixture of magnetic powder and thermosetting adhesive to make rubber powder;

[0074] (3) Gained rubber powder and 0.1 part of zin...

example 2

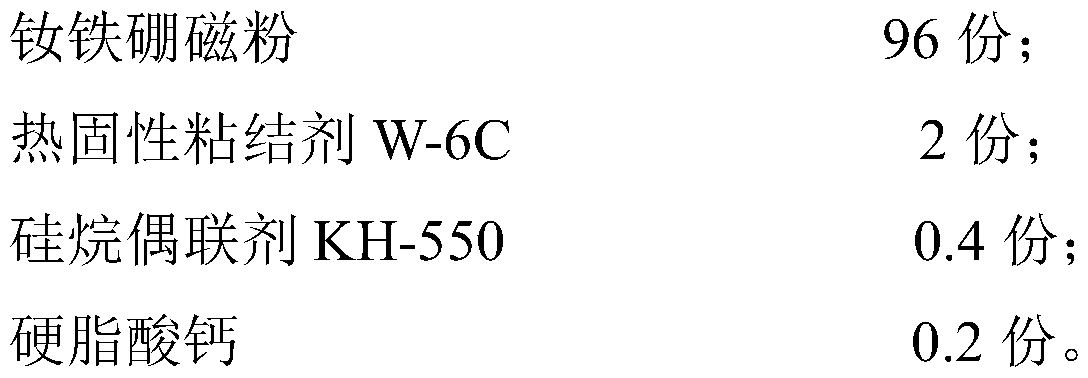

[0079] The bonded NdFeB magnet provided in this example is composed of the following components by weight:

[0080]

[0081] And the particle size of the binder powder in this example is 300 mesh.

[0082] In this example, the preparation of bonded NdFeB magnets is completed through the following process:

[0083] (1) Crushing the required NdFeB magnetic powder through a 300-mesh sieve;

[0084] (2) Add 96 parts of sieved NdFeB magnetic powder and 2 parts of powdery thermosetting binder W-6C into the mixing equipment and stir evenly, then pass 6 parts of acetone solution with 0.4 parts of coupling agent through the mist Chemical equipment is evenly sprayed onto the surface of the mixture of magnetic powder and thermosetting adhesive to make rubber powder;

[0085] (3) Gained rubber powder and 0.2 part of calcium stearate are evenly combined to obtain a magnetic powder mixture;

[0086] (4) putting the obtained magnetic powder mixture into a mold and pressing to obtain a ...

example 3

[0090] The bonded NdFeB magnet provided in this example is composed of the following components by weight:

[0091]

[0092]

[0093] And the particle size of the binder powder in this example is 300 mesh.

[0094] In this example, the preparation of bonded NdFeB magnets is completed through the following process:

[0095] (1) Crushing the required NdFeB magnetic powder through a 400-mesh sieve;

[0096] (2) Add 97 parts of sieved NdFeB magnetic powder and 2.5 parts of powdery thermosetting binder W-6C into the mixing equipment and stir evenly, then pass 7 parts of acetone solution with 0.5 parts of coupling agent through the mist Chemical equipment is evenly sprayed onto the surface of the mixture of magnetic powder and thermosetting adhesive to make rubber powder;

[0097] (3) Gained rubber powder and 0.4 part of calcium stearate are evenly combined to obtain a magnetic powder mixture;

[0098] (4) putting the obtained magnetic powder mixture into a mold and pressin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com