Protein synthesis system for in-vitro protein synthesis, kit and preparation method for protein through in-vitro synthesis

A technology of protein synthesis and protein synthesis, applied in the biological field, can solve the problems of high cost, high cost, and difficulty in eukaryotic cell culture, and achieve high yield and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0132] In the present invention, the preparation method of the yeast cell extract is not limited, and a preferred preparation method includes the following steps:

[0133] (i) providing yeast cells;

[0134] (ii) washing the yeast cells to obtain washed yeast cells;

[0135] (iii) subjecting the washed yeast cells to destructive treatment to obtain crude yeast extract;

[0136] (iv) performing solid-liquid separation on the crude yeast extract to obtain the liquid part, which is the yeast cell extract.

[0137] In the present invention, the solid-liquid separation method is not particularly limited, and a preferred method is centrifugation.

[0138] In a preferred embodiment, said centrifugation is performed in a liquid state.

[0139] In the present invention, the centrifugation conditions are not particularly limited, and a preferred centrifugation condition is 5000-100000×g, preferably 8000-30000×g.

[0140] In the present invention, the centrifugation time is not parti...

Embodiment 1

[0171] Embodiment 1: high pressure crushing prepares yeast cell extract

[0172] 1.1 Preparation of yeast seed liquid: Pick a single colony of Kluyveromyces lactis from the plate and inoculate it in 50 mL of YPD medium (the composition of YPD medium is: 1% yeast extract, 2% peptone, 2% glucose , pH 5.5) in a 250 mL Erlenmeyer flask (filling volume is 20%, the same below), and the inoculated Erlenmeyer flask was placed in a shaker for cultivation, culture conditions: temperature is 30 ° C, rotation speed is 200 rpm, After culturing for 24 h, the seed solution was obtained;

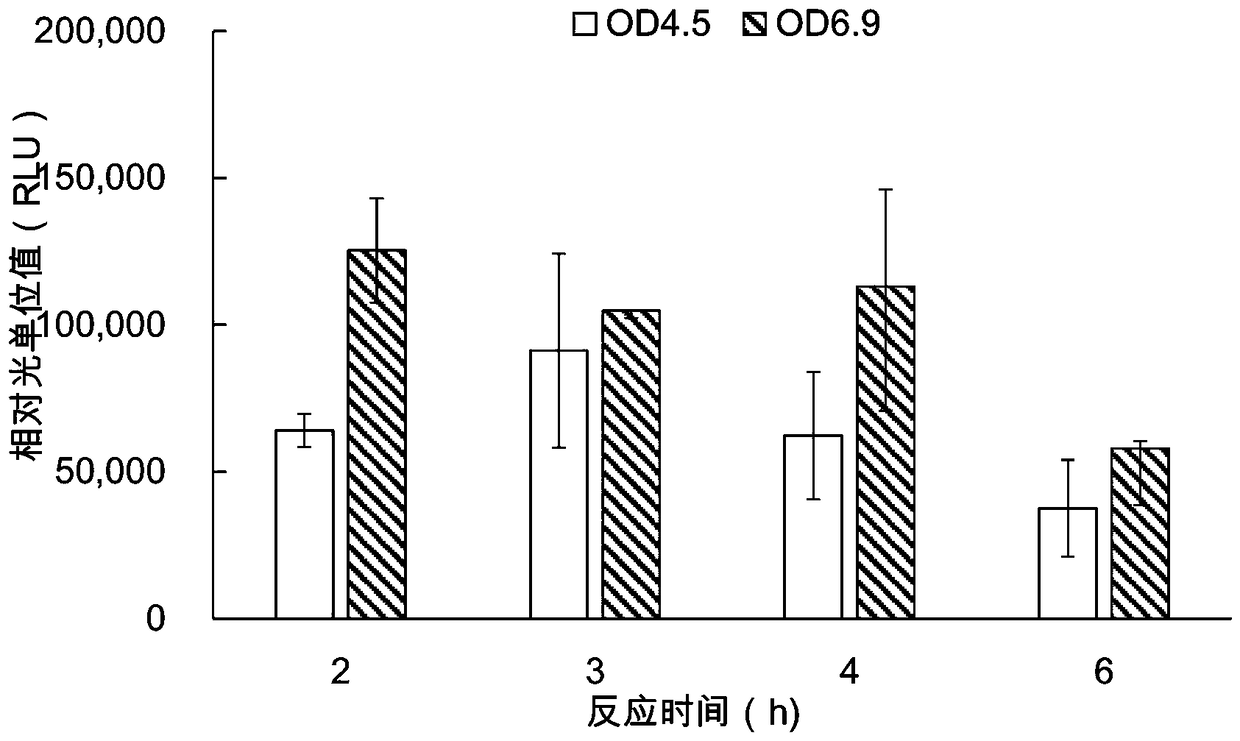

[0173] 1.2 Yeast cell culture: Inoculate the seed liquid prepared in 1.1 into a 2 L Erlenmeyer flask containing 400 mL of LYPD medium according to the inoculum amount of 0.1-1%, and place it in a shaker for culture. The culture condition: the temperature is 30 °C, the rotation speed is 200rpm. In the middle and late stages of the logarithmic phase of yeast growth (OD600=3.0-6.9), the culture is terminated...

Embodiment 2

[0184] Embodiment 2: liquid nitrogen crushing method prepares yeast cell extract

[0185] 2.1 Preparation of yeast seed liquid: Pick a single colony of Kluyveromyces lactis from the plate and inoculate it in 50 mL of YPD medium (the composition of YPD medium is: 1% yeast extract, 2% peptone, 2% glucose , pH 5.5) in a 250 mL Erlenmeyer flask (filling volume is 20%, the same below), and the inoculated Erlenmeyer flask was placed in a shaker for culture, culture conditions: temperature 30 ℃, rotation speed 200 rpm. After culturing for 24 h, the seed solution was obtained;

[0186] 2.2 Yeast cell culture: Inoculate the seed liquid prepared in 2.1 into a 2 L Erlenmeyer flask containing 400 mL of LYPD medium according to the inoculum amount of 0.1-1%, and place it in a shaker for culture. The culture condition: the temperature is 30 °C, the rotation speed is 200rpm. In the middle and late stages of the logarithmic phase of yeast growth (OD600=3.0-6.9), the culture is terminated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com