Multistage flow safety valve for oil production

A technology of safety valve and flow rate, which is applied in the direction of the device for absorbing fluid energy of the valve, sliding valve, valve details, etc. It can solve the problems of inaccurate flow control accuracy and multi-level control of the flow control valve, so as to achieve accurate flow control , reduce collision, convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

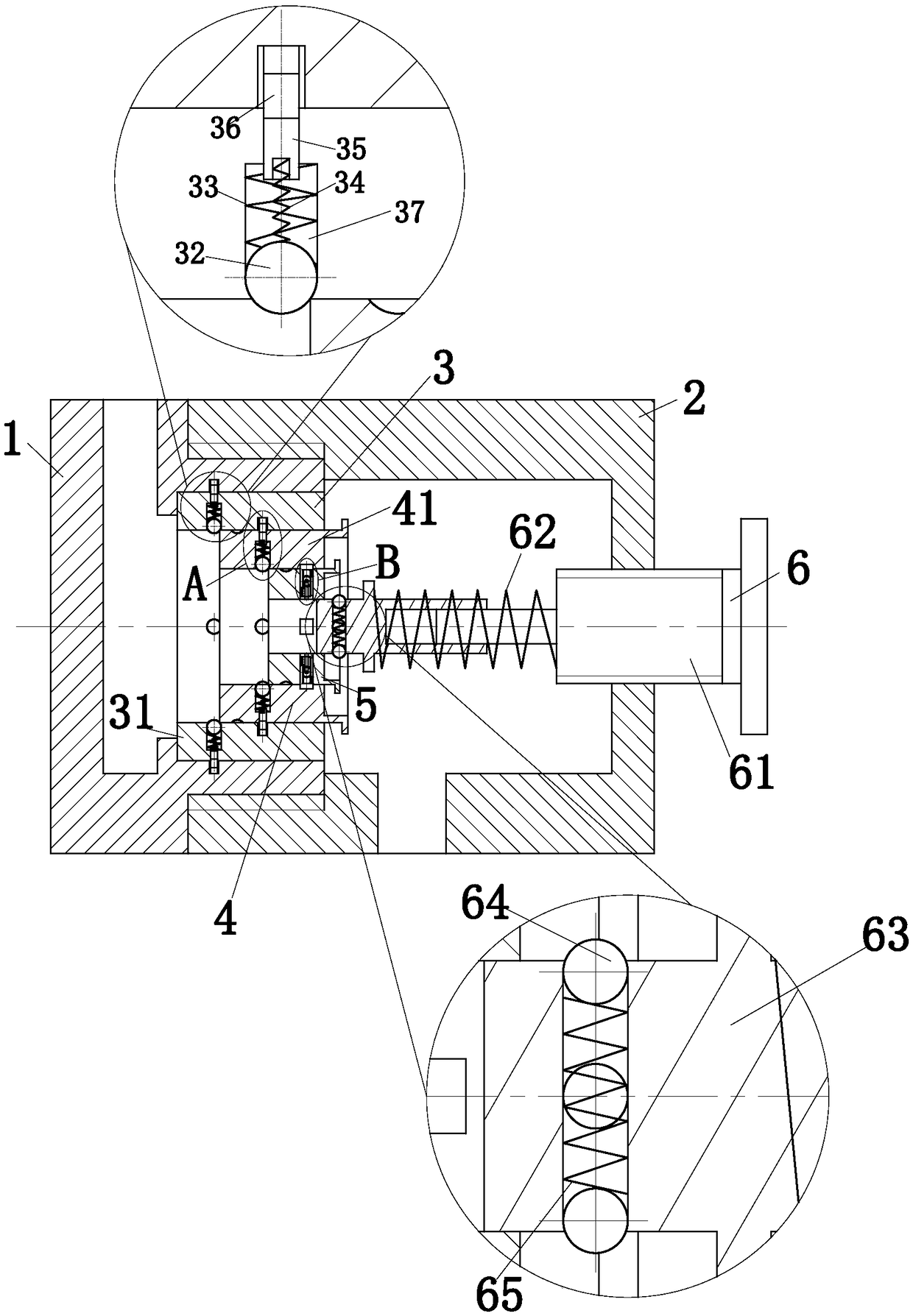

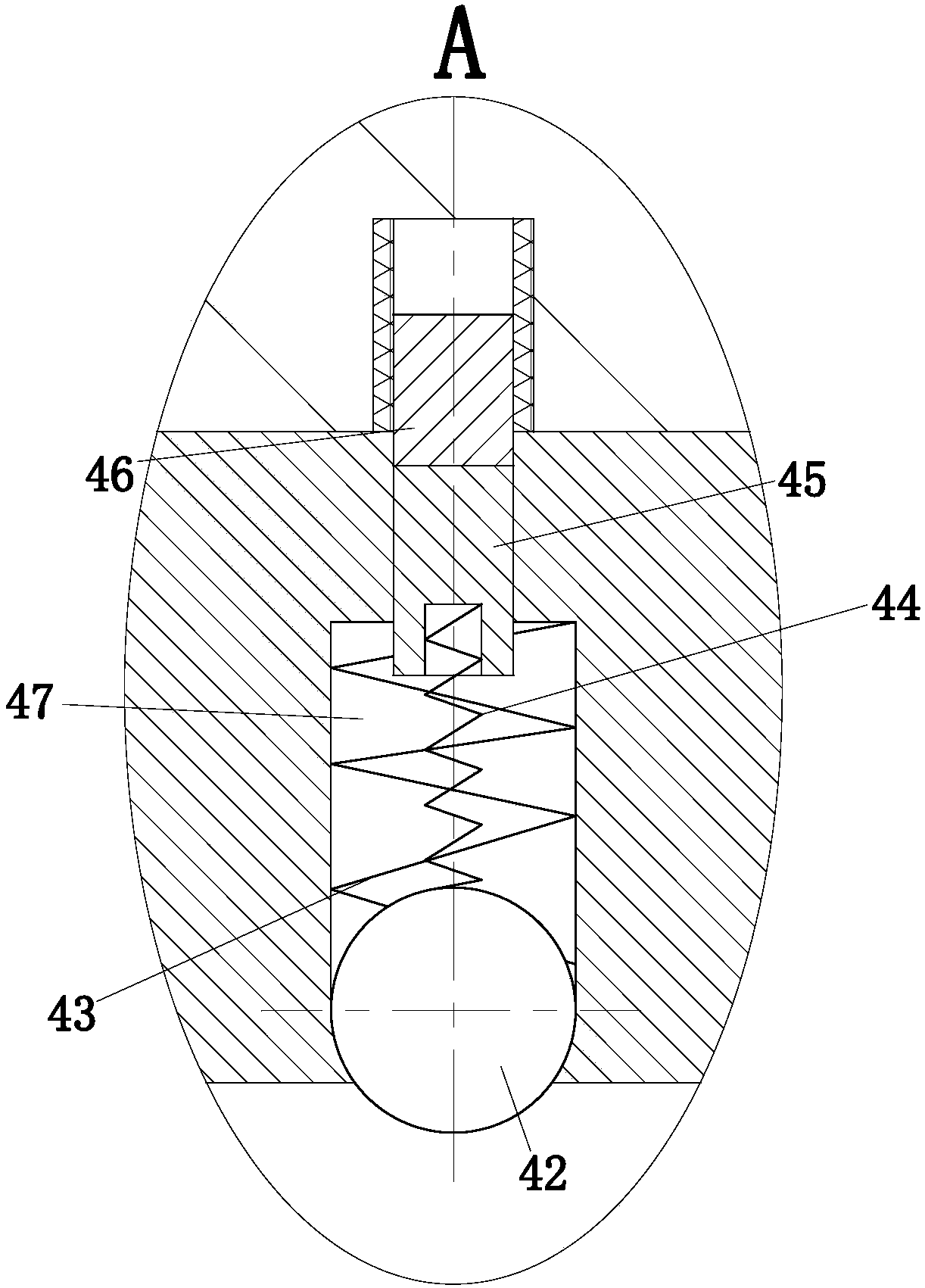

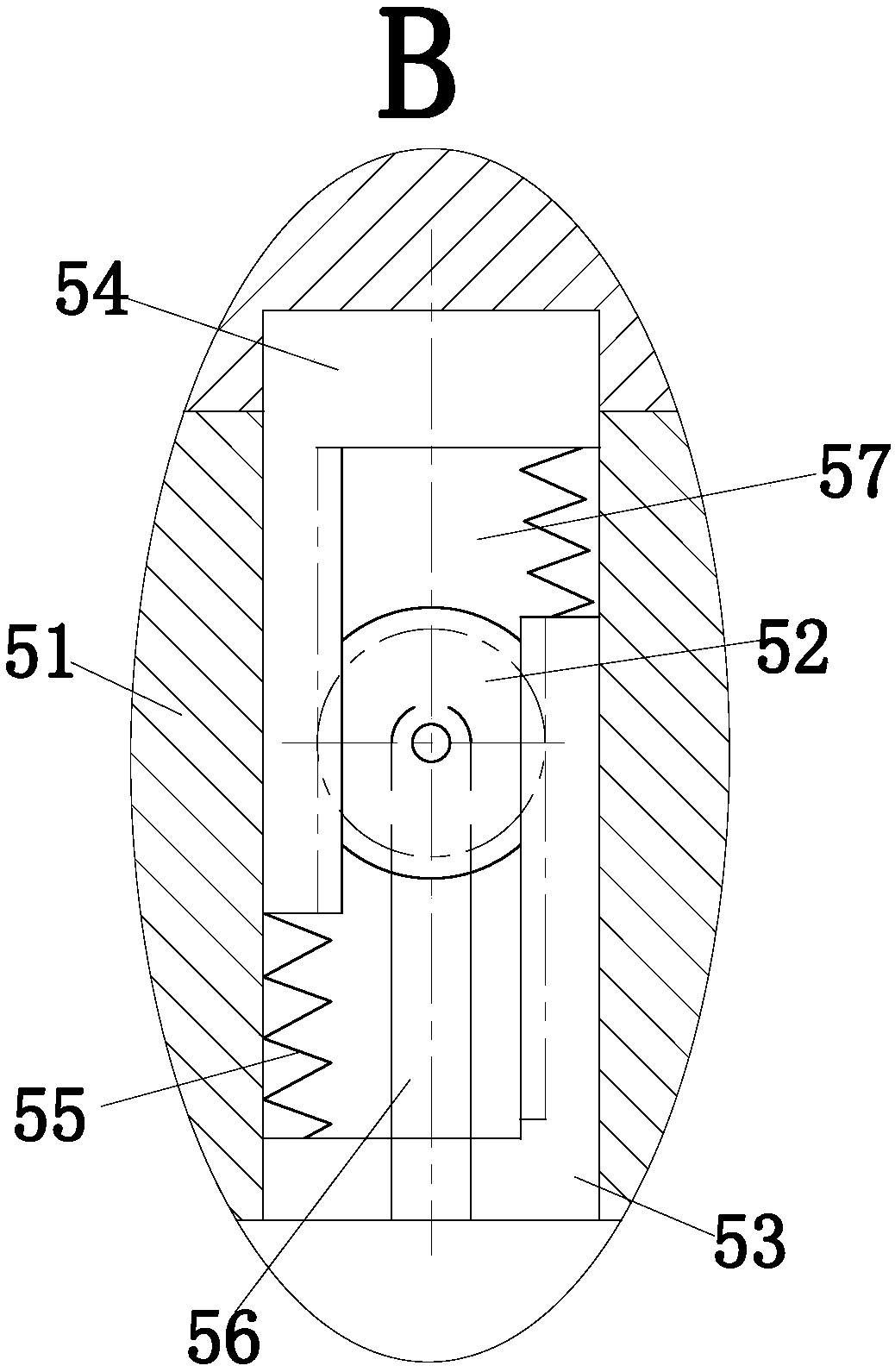

[0024] As an embodiment of the present invention, the first valve module 3 includes a first valve plug 31, a ball one 32, a spring one 33, a spring five 34, a push block one 35 and a slider one 36. A valve plug 31 is provided with a No. 1 groove 37, the first valve plug 31 is annular, and the inner wall of the second valve plug 41 is also provided with a groove corresponding to the No. 2 groove 47, and a rubber anti-skid pad is built in the groove; The ball one 32 is located in the first groove 37, and the outer wall of the second valve plug 41 is provided with a hemispherical groove; one end of the spring one 33 is fixedly connected with the ball one 32, and the other end of the spring one 33 Connected with the first valve plug 31, the elasticity of spring one 33 is greater than that of spring two 43; one end of said spring five 34 is fixedly connected with ball one 32; the other end of said push block one 35 and spring five 34 connection; the slider one 36 is in contact with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com