Pole tower and transformer substation grounding calcium bentonite base resistance reducing agent

A technology of calcium-based bentonite and resistance reducing agent, which is applied in the field of electric power grounding materials, can solve the problems that the grounding resistance of the grounding system is difficult to meet the power industry standard, the soil resistivity is high, and the amount of steel is increased, so as to achieve good economic effects. Less, the effect of increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

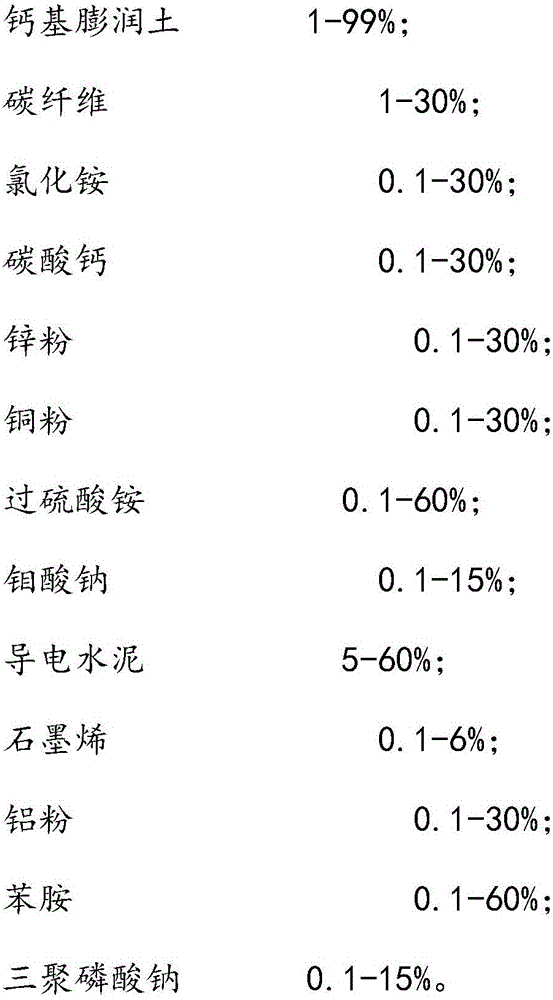

Method used

Image

Examples

Embodiment 1

[0031] The first step, take 10 parts of ammonium persulfate, 1 part of sodium tripolyphosphate, and 1 part of sodium molybdate to make a mixed solution, wherein the mass ratio of ammonium persulfate, sodium tripolyphosphate, sodium molybdate to water is 1:6 .

[0032] In the second step, 10 parts of aniline, 10 parts of ammonium chloride, and 26 parts of calcium-based bentonite were added to the mixed solution, wherein the mass ratio of aniline, ammonium chloride, calcium-based bentonite to the mixed solution was 1:1, and mechanically stirred for 30 minutes. Leave for 4 hours.

[0033] In the third step, 8 parts of carbon fiber, 2 parts of graphene, 1 part of zinc powder, 1 part of aluminum powder and 10 parts of calcium carbonate are added to the above mixture and mixed evenly.

[0034] The fourth step, finally add 20 parts of conductive cement, mix evenly and wrap around the grounding body.

Embodiment 2

[0036] In the first step, get 8 parts of ammonium persulfate, 1.5 parts of sodium tripolyphosphate, and 1.5 parts of sodium molybdate to make a mixed solution, wherein the mass ratio of ammonium persulfate, sodium tripolyphosphate, sodium molybdate to water is 1:6 .

[0037] In the second step, 8 parts of aniline, 9 parts of ammonium chloride, and 25 parts of calcium-based bentonite were added to the mixed solution, wherein the mass ratio of aniline, ammonium chloride, calcium-based bentonite to the mixed solution was 1:1, and mechanically stirred for 40 minutes. Leave for 5 hours.

[0038] Step 3: Add 9 parts of carbon fiber, 1 part of graphene, 1 part of zinc powder, 1 part of aluminum powder, 1 part of copper powder, and 9 parts of calcium carbonate into the above mixture, and mix well.

[0039] The fourth step, finally add 25 parts of conductive cement, mix evenly and wrap around the grounding body.

Embodiment 3

[0041] In the first step, get 7 parts of ammonium persulfate, 2 parts of sodium tripolyphosphate, and 2 parts of sodium molybdate to make a mixed solution, wherein the mass ratio of ammonium persulfate, sodium tripolyphosphate, sodium molybdate to water is 1:6 .

[0042] In the second step, 7 parts of aniline, 8 parts of ammonium chloride, and 30 parts of calcium-based bentonite were added to the mixed solution, wherein the mass ratio of aniline, ammonium chloride, calcium-based bentonite to the mixed solution was 1:1, and mechanically stirred for 30 minutes. Leave for 5 hours.

[0043] In the third step, 9 parts of carbon fiber, 3 parts of graphene, 2 parts of zinc powder, 2 parts of copper powder and 8 parts of calcium carbonate were added to the above mixture and mixed evenly.

[0044] The fourth step, finally add 20 parts of conductive cement, mix evenly and wrap around the grounding body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com