Loader closed type static hydraulic driving system

A hydrostatic drive, loader technology, applied in mechanical equipment, fluid pressure actuation devices, servo motors, etc., can solve the problem of wheels falling to a safe value, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

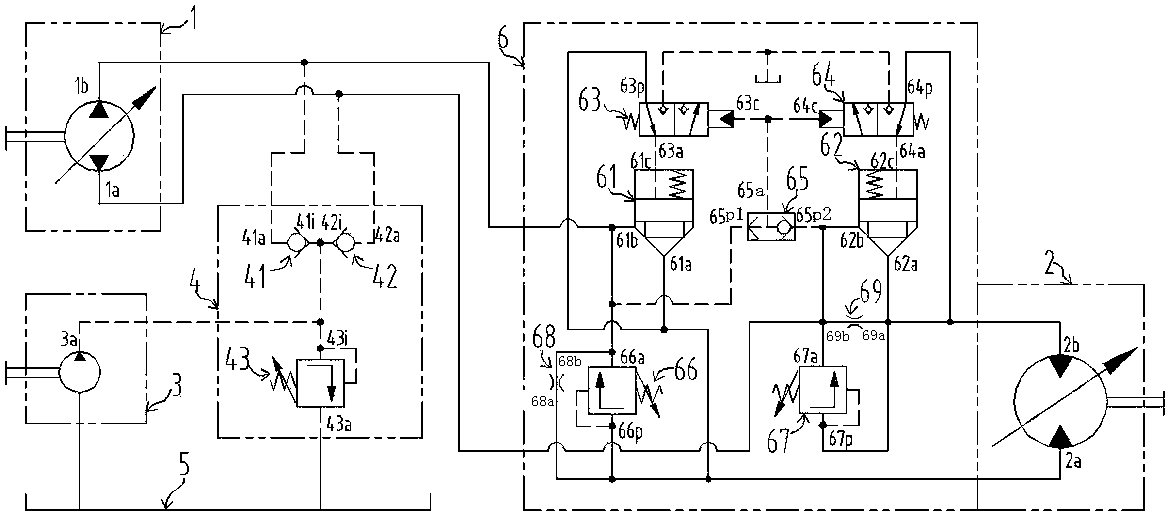

[0019] figure 1 The closed hydrostatic drive system of the loader shown includes a closed pipeline formed by connecting the hydraulic pump 1 and the hydraulic motor 2. The hydraulic pump 1 is a one-way rotating two-way variable-displacement pump; Displacement motor; between the hydraulic pump 1 and the hydraulic motor 2, there is an oil charge valve group 4 and an anti-rupture valve group 6 in sequence, and the oil charge valve group 4 is connected with the fuel tank 5 through the oil charge pump 3; the anti-rupture valve group 6 includes a The shuttle valve 65 obtains the control high pressure in the system, and is controlled by the hydraulic control valve to open or close the two-way cartridge valve; wherein the two-way cartridge valve includes the first two-way cartridge valve 61 and the second two-way cartridge valve 62; the hydraulic control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com