Process for production of a screw for an extruder, and screw

A technology of extruders and screws, applied in the direction of presses, manufacturing tools, material forming presses, etc., can solve the problems of tungsten carbide being hard and impossible to achieve, and achieve the effect of reducing the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

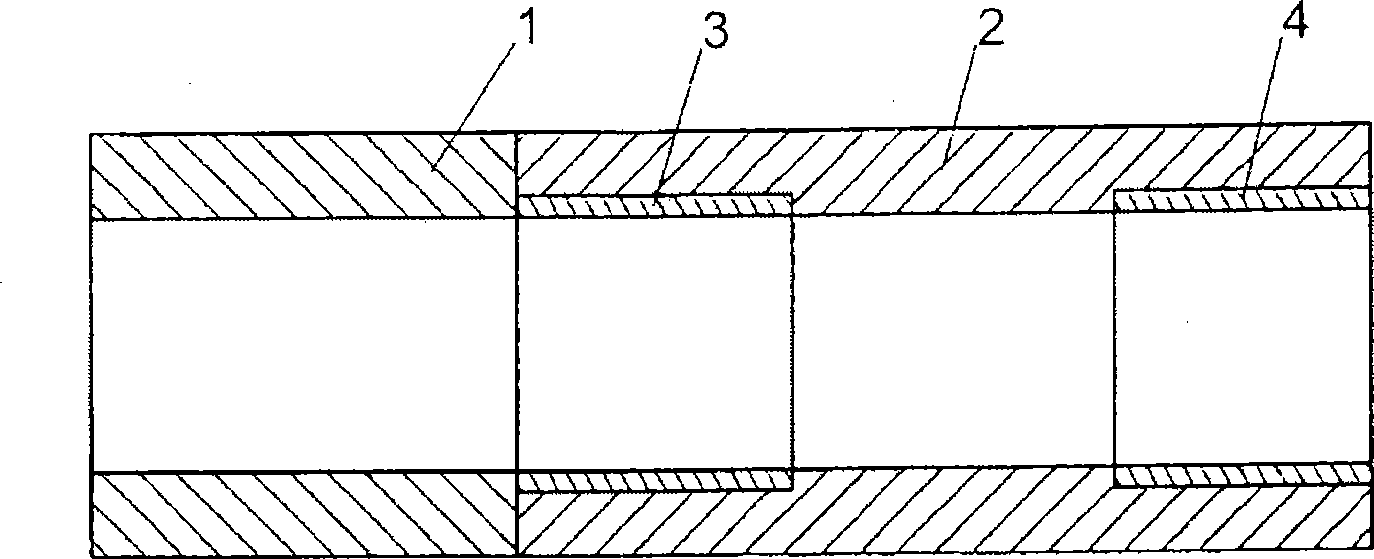

[0032] according to figure 1 The extruder housing comprises parts 1 and 2, which are connected to each other by flanges (not shown). Before the two parts 1 and 2 are connected to one another, a wear-resistant material is introduced into the two-sided part 2 . The wear-resistant material is figure 1 is represented by the insert 3 in the form of a sleeve.

[0033] The said screw should be coated in the region of the inserts 3 and 4 with a wear protection layer, for example with tungsten carbide, but in the remaining regions with a sliding layer, for example with molybdenum.

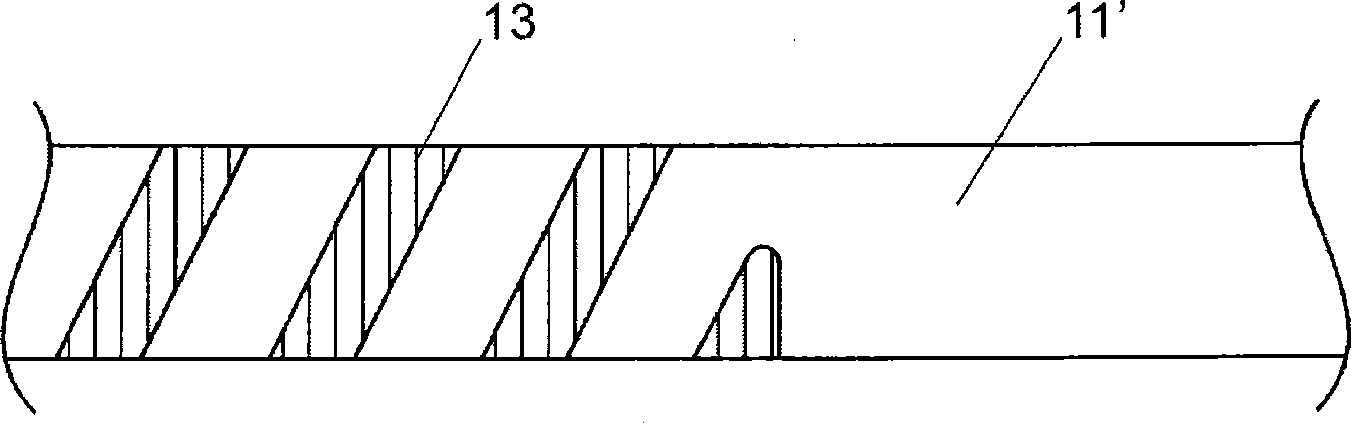

[0034] according to Figure 2 to Figure 6 The manufacturing process of such a screw is illustrated. The figures each show an axial region of the screw (or the base body of the screw) in which the transition from tungsten carbide to molybdenum is located (or should be located).

[0035] First, the bed 12 is milled out on the cylindrical base body 11' of the screw, specifically only in the region where t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com