Oil-containing pollutant treatment method performing indirect heating using heat-conducting oil and device thereof

A pollutant treatment and treatment device technology, which is applied in the field of oily pollutant treatment, can solve the problems of difficult control of new pollution sources in soil remediation projects, insufficient understanding of different pollutants, and poor applicability of equipment, so as to avoid internal coking and solid waste. Particle and dust contamination, effect of accelerated pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for treating oily pollutants utilizing heat transfer oil indirect heating of the present invention, the steps are as follows:

[0020] a. Crushing: breaking the large oily pollutants into pieces A, and the pieces A have a particle size of 10mm or 20mm or 40mm;

[0021] b. Hot washing: Put the fragment A obtained in step a into 60°C water and stir for 10 minutes or 15 minutes or 20 minutes. The mass ratio of fragment A to water is 1:10 or 1:15 or 1:20. Oil, water and Sludge B is separated, the obtained oil is exported, and the water is returned to continue to be recycled;

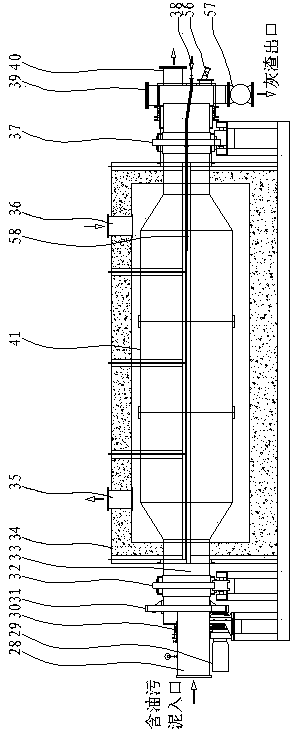

[0022] c. Thermal desorption: Preheat the oil sludge B obtained in step b with heat transfer oil at 100°C or 150°C or 200°C, and then heat it to 400°C with negative pressure rotation for 1 or 2 hours, rotating at a speed of 10 rpm , the pressure is controlled at -150KPa~150KPa, and oil gas C and ash D are obtained;

[0023] d. Oil and gas treatment: After the solids are removed from the oil...

Embodiment 2

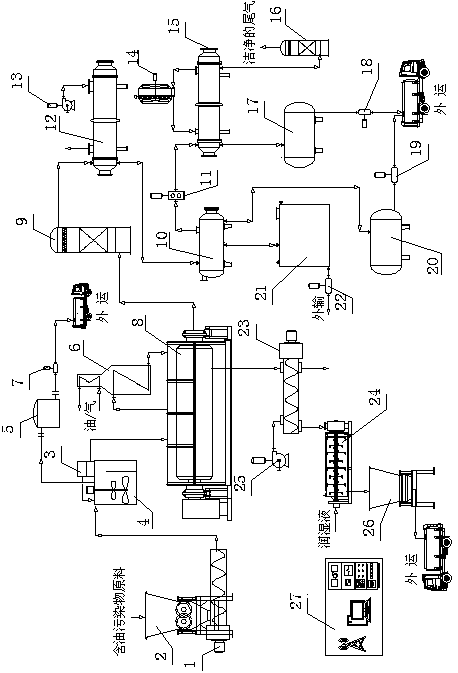

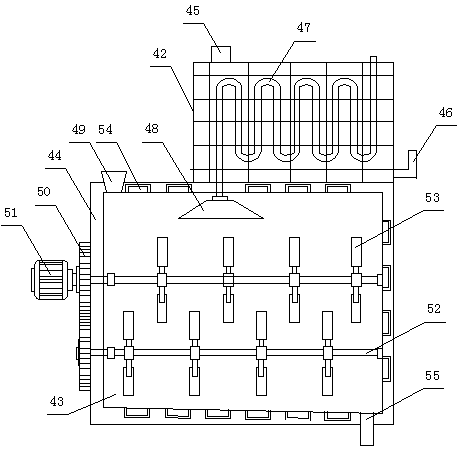

[0026] Such as figure 1As shown, a treatment device for oily pollutants using heat transfer oil indirect heating of the present invention is composed of a crusher 2, a thermal desorption device 8 and a separation device. The outlet end of the crusher 2 is connected to a screw conveyor 1, and the screw conveyor Conveyor 1 is connected to the inlet end pipeline of hot washing device 4, and the material is crushed by crusher 2 and then spirally transported to hot washing device 4. Hot washing device 4 uses high temperature to separate the oil in oily sludge for the first time. 4. It is equipped with a heating device, a stirring device and a dosing device inside. The heating device heats the raw materials to promote the separation of the oil phase; a certain amount of water is added to the tank to facilitate stirring, and then the demulsifier and flocculation are added by the dosing device After the solvent is added, the oil phase separation is further promoted, and the separated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com