Oil-containing pollutant treatment system capable of realizing energy-saving control by using PID (Proportion Integration Differentiation) to adjust constant pressure

A pollutant treatment and energy-saving control technology, which is applied in the direction of electric fluid pressure control, pyrolysis sludge treatment, petroleum industry, etc., can solve the problems of intermittent and discontinuous operation, unstable system operation, high safety risk, etc., to reduce Effects of operating cost, realization of resource utilization, and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

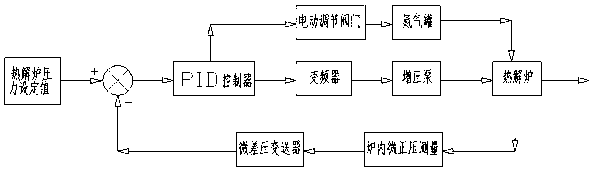

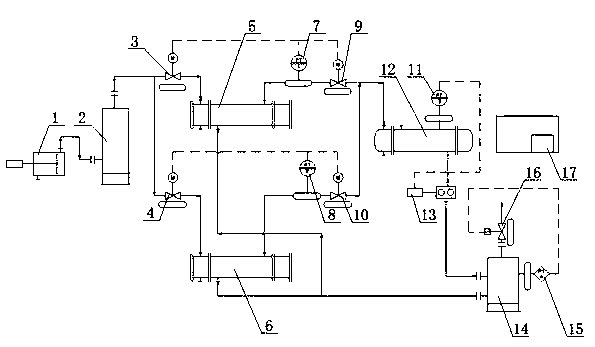

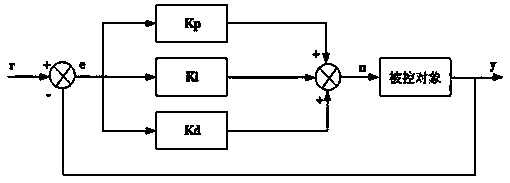

[0017] refer to Figure 1-3 , an oily pollutant treatment system that realizes energy-saving control through PID regulation and constant pressure, including a nitrogen generator 1, a nitrogen tank 2, a first electric regulating valve 3, a second electric regulating valve 4, a third electric regulating valve 9, and a second electric regulating valve. Four electric regulating valves 10, the first pyrolysis furnace 5, the second pyrolysis furnace 6, the first differential pressure transmitter 7, the second differential pressure transmitter 8, the third differential pressure transmitter 11, The fourth differential pressure transmitter 15, buffer tank group 12, booster pump 13, non-condensable gas buffer tank 14, electric switch valve 16 and a PID controller 17; the nitrogen generator 1 passes through the pipeline and the nitrogen tank 2 connection, the nitrogen tank 2 is connected with the first pyrolysis furnace 5 and the second pyrolysis furnace 6 through the pipeline, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com