Method for improving polyimide slurry production efficiency

A technology of polyimide slurry and production efficiency, applied in the production of bulk chemicals, etc., can solve the problems of affecting performance, difficult storage and recycling, and extremely high environmental requirements, and achieves improved activity and selectivity. Period, the effect of increasing the movement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

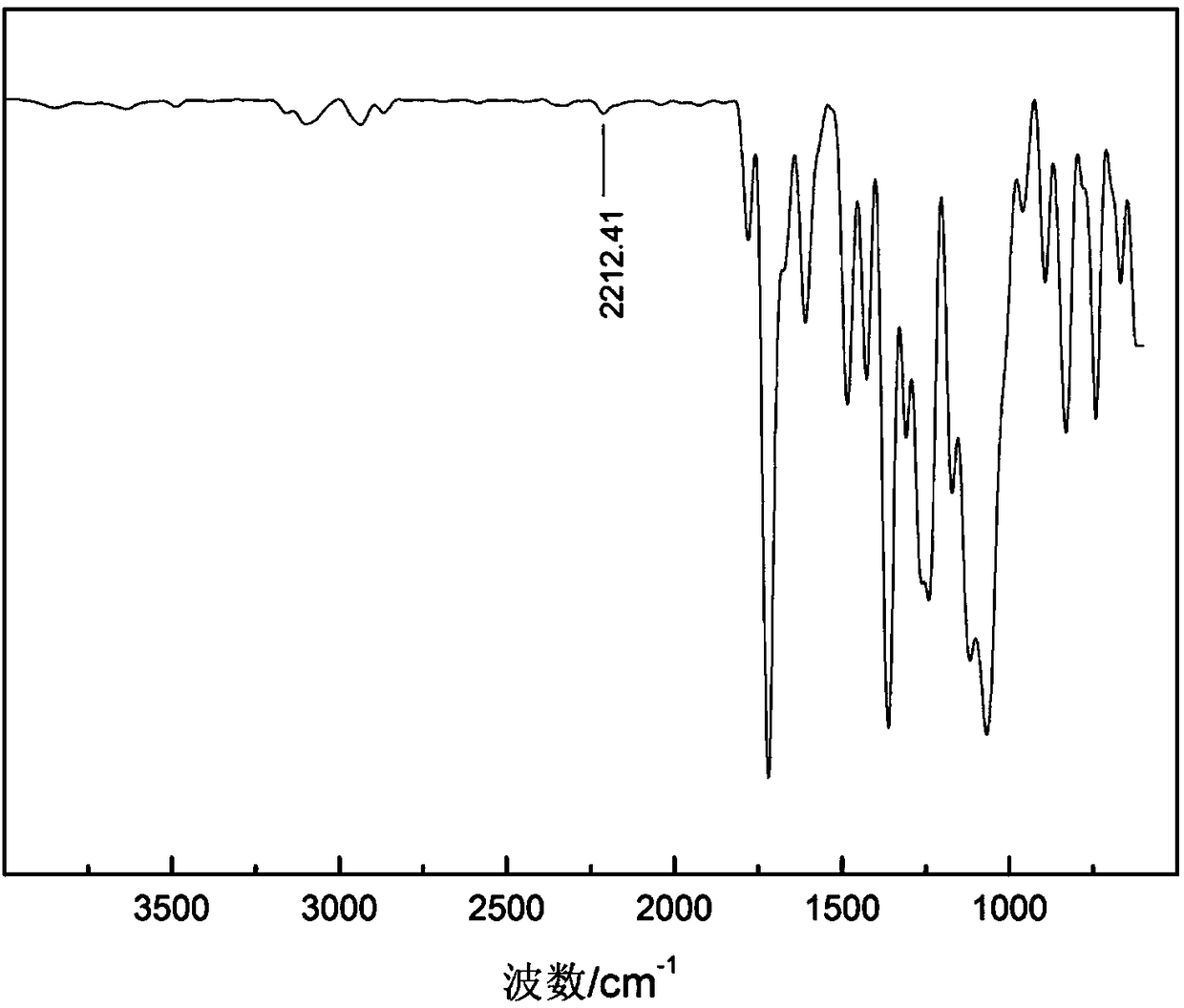

Image

Examples

Embodiment 1

[0023] Under nitrogen protection, 0.713g ionic liquid (0.475g 1-hexyl-3-methylimidazolium tetrafluoroborate and 0.238g 1-butyl-3-methyl imidazole hexafluorophosphate) to form 72g mixed solvent, at room temperature, mix 1.394g (0.0052mol) 1,1-bis(4-aminophenyl) cyclohexane BAPC and 16.645g (0.052mol) TFMB Dissolve the diamine in a strictly dry mixed solvent, stir mechanically until it is completely dissolved, add 17.366g (0.0560mol) ODPA to it, continue stirring for 1h, then add 0.595g (0.0024mol) 4-PEPA, stir and age for 12h to obtain Polyamic acid solution with capping agent.

[0024] Add 8.235g (0.056mol) of phthalimide to the polyamic acid solution, stir at room temperature for 4h, and obtain a polyimide prepolymer solution after the reaction is completed, and precipitate the polyimide prepolymer solution into methanol, filtered, washed, and dried at 60°C to obtain solid polyimide prepolymer, which is dissolved in NMP to obtain polyimide prepolymer glue, with a solid conte...

Embodiment 2

[0027]Under the protection of nitrogen, 0.716g ionic liquid (0.409g 1-hexyl-3-methylimidazolium tetrafluoroborate and 0.307g 1-butyl-3-methyl imidazole hexafluorophosphate) to form 144g mixed solvent, at room temperature, 7.937g (0.0296mol) 1,1-bis(4-aminophenyl) cyclohexane BAPC and 9.477g (0.0296mol) TFMB Dissolve in 20g of strictly dry mixed solvent, under nitrogen protection, mechanically stir until completely dissolved, add 17.99g (0.058mol) ODPA to it, continue stirring for 1h, then add 0.595g (0.0024mol) 4-PEPA, stir and age After 12 hours, a polyamic acid solution with an end-capping agent was obtained.

[0028] 12.796g (0.087mol) of phthalimide was added to the polyamic acid solution, stirred at room temperature for 3.5h, the reaction was completed to obtain a polyimide prepolymer solution, and the polyimide prepolymer solution was Precipitate into methanol, filter, wash, and dry at 60°C to obtain polyimide prepolymer solid, dissolve in DMF to obtain polyimide prepol...

Embodiment 3

[0031] Under nitrogen protection, add 0.252g ionic liquid (0.126g 1-hexyl-3-methylimidazolium tetrafluoroborate and 0.126g 1-butyl -3-Methylimidazole hexafluorophosphate mixed) to form 252g mixed solvent, 2.572g (0.0096mol) 1,1-bis(4-aminophenyl) cyclohexane BAPC and 15.355g (0.048 mol) of TFMB was dissolved in a strictly dry mixed solvent, mechanically stirred until it was completely dissolved, and then 17.478g (0.0564mol) ODPA was added to it, and after stirring for 1 hour, 0.595g (0.0024mol) 4-PEPA was added to it, and aged with stirring After 12 hours, a polyamic acid solution with an end-capping agent was obtained.

[0032] 16.576g (0.1128mol) of phthalimide was added to the polyamic acid solution, stirred at room temperature for 2h, and the polyimide prepolymer solution was obtained after the reaction, and the polyimide prepolymer solution was Precipitate into methanol, filter, wash, and dry at 60°C to obtain polyimide prepolymer solid, dissolve in DMF to obtain polyimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com