Injection molding mold with flange plastic exhausting pipe

An injection molding and plastic technology, applied in the field of plastic molds, can solve the problems of poor operation stability, poor product quality, and low production efficiency, and achieve the effects of high production efficiency, simple structure, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

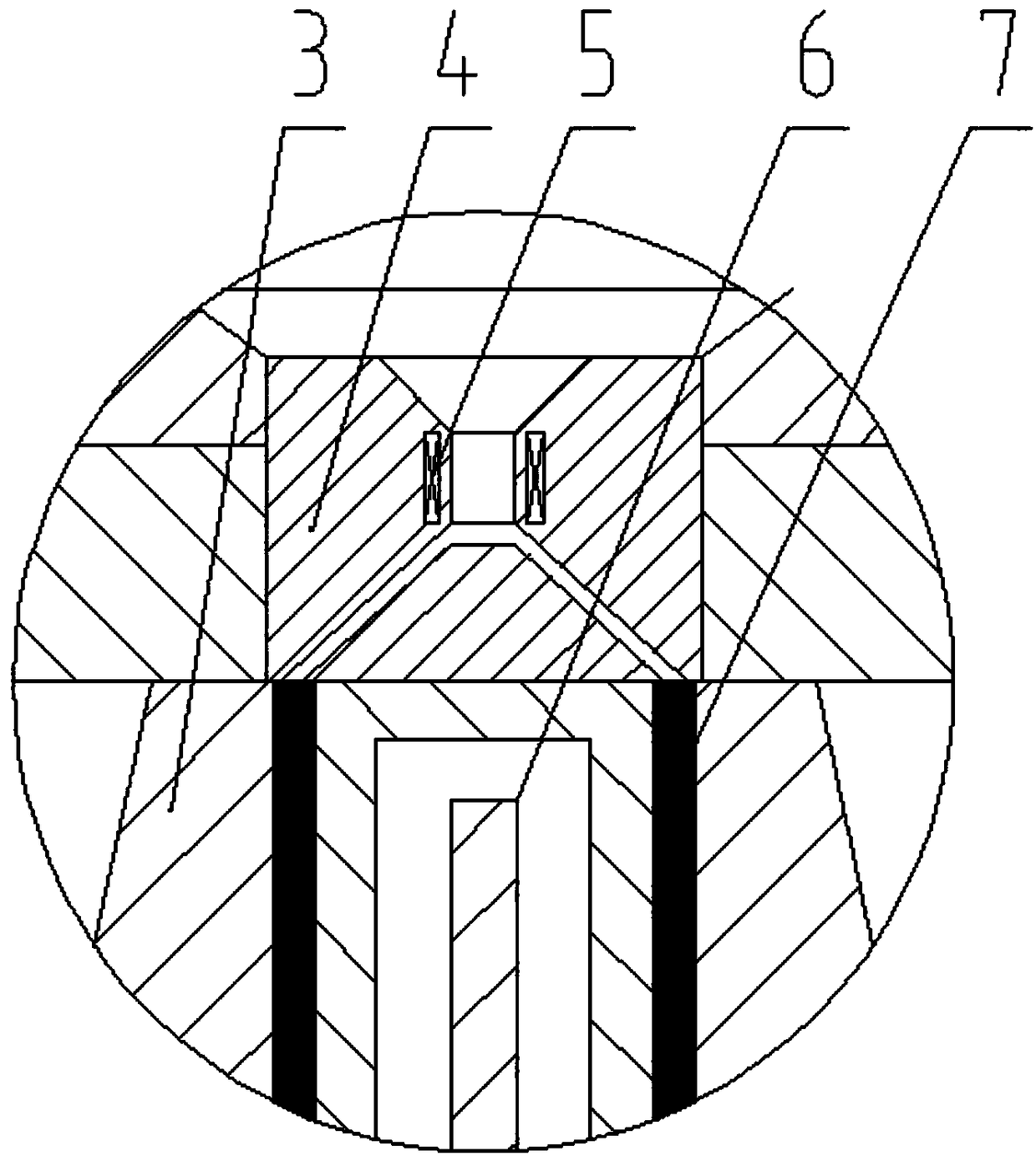

[0016] see figure 1 , figure 2 , image 3 , Figure 4 , a plastic nozzle injection molding mold with a flange, comprising a parting die 3, a core 17, and a push plate 16, the parting die 3 is composed of 3-4 mold petals, and the lower end of the middle part of the mold petals is provided with Slider 12, the outside of parting mold 3 is a tapered structure, and core 17 is provided in the cavity inside parting mold 3, and the outside of described core 17 bottom is provided with push plate 16, and described push plate 16 is positioned at The bottom of core 17, between described core 17, push plate 16, parting mold 3, be provided with injection mold cavity 7, described slide block 12 is arranged in the chute on the parting mold fixed plate 9, slide block The end of 12 is connected with outer cover plate 10 by spring 11, and described spring 11 is positioned at chute, and the outer side of described parting mold 3 bottom is provided with the sliding sleeve 8 that matches with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com