GaAs-base bi-color quantum well infrared detector based on resonance tunneling effect

A technology of infrared detectors and quantum wells, applied in semiconductor devices, sustainable manufacturing/processing, electrical components, etc., can solve the problems of complex device preparation process, difficult material growth, incompatible preparation process, etc., to simplify material growth , reduce dark current, increase the effect of operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

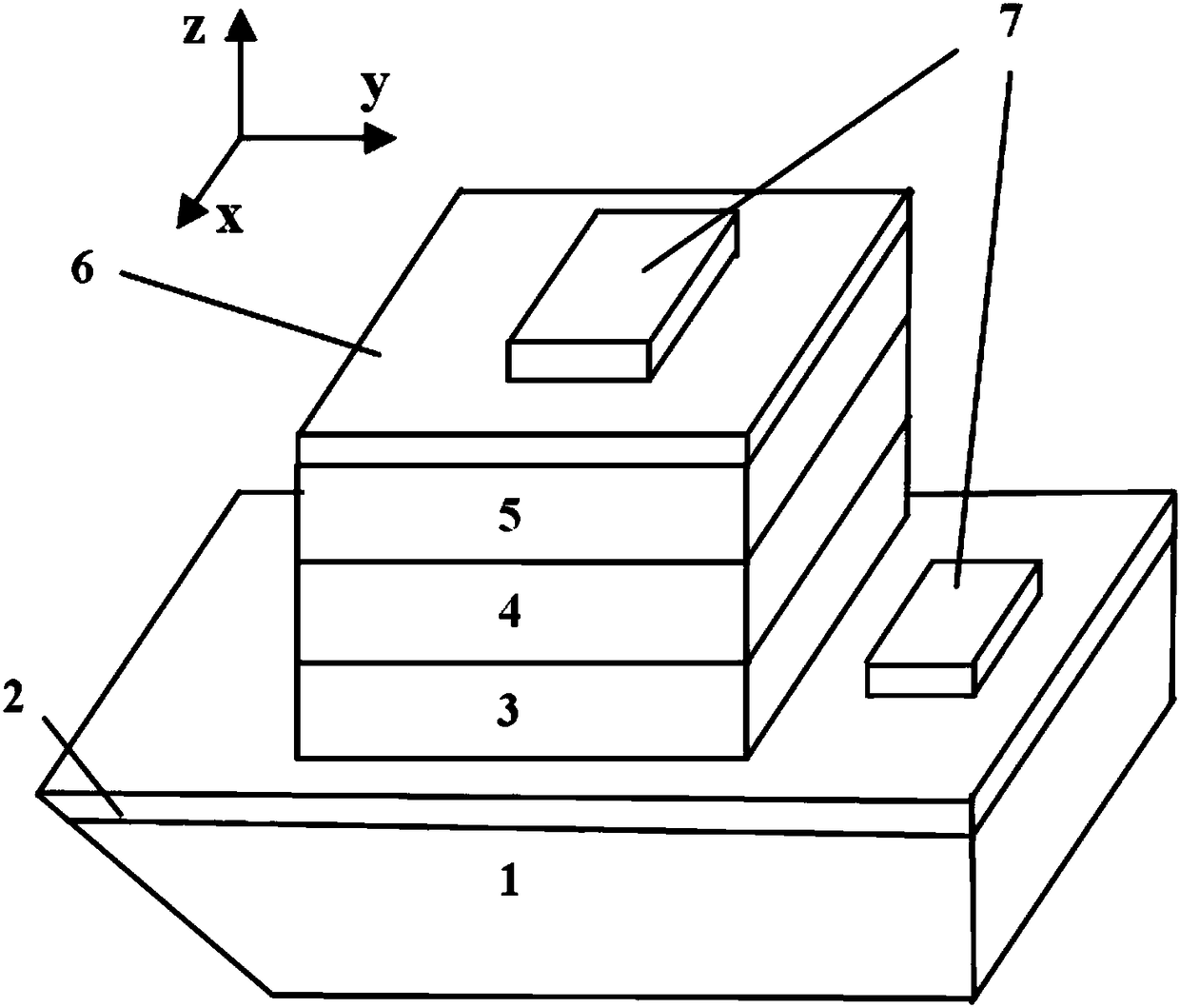

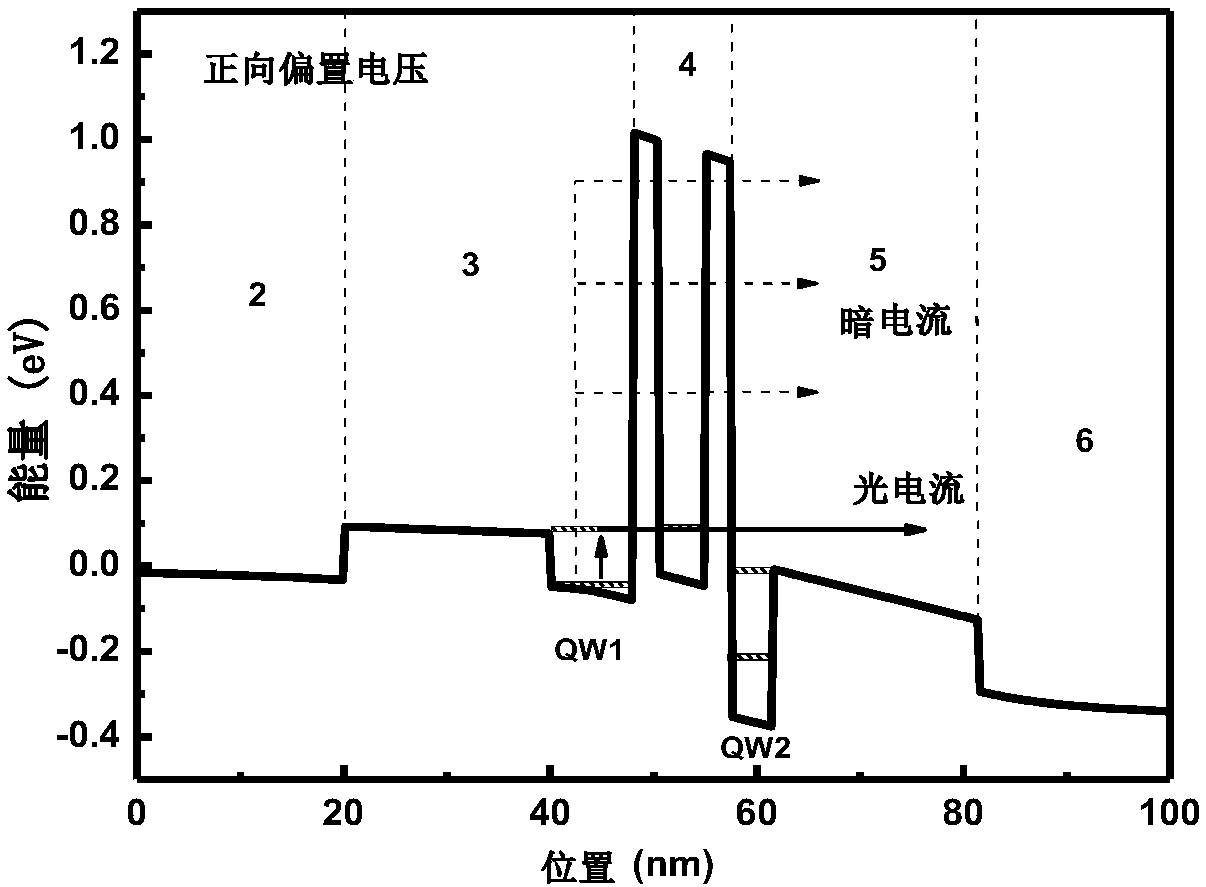

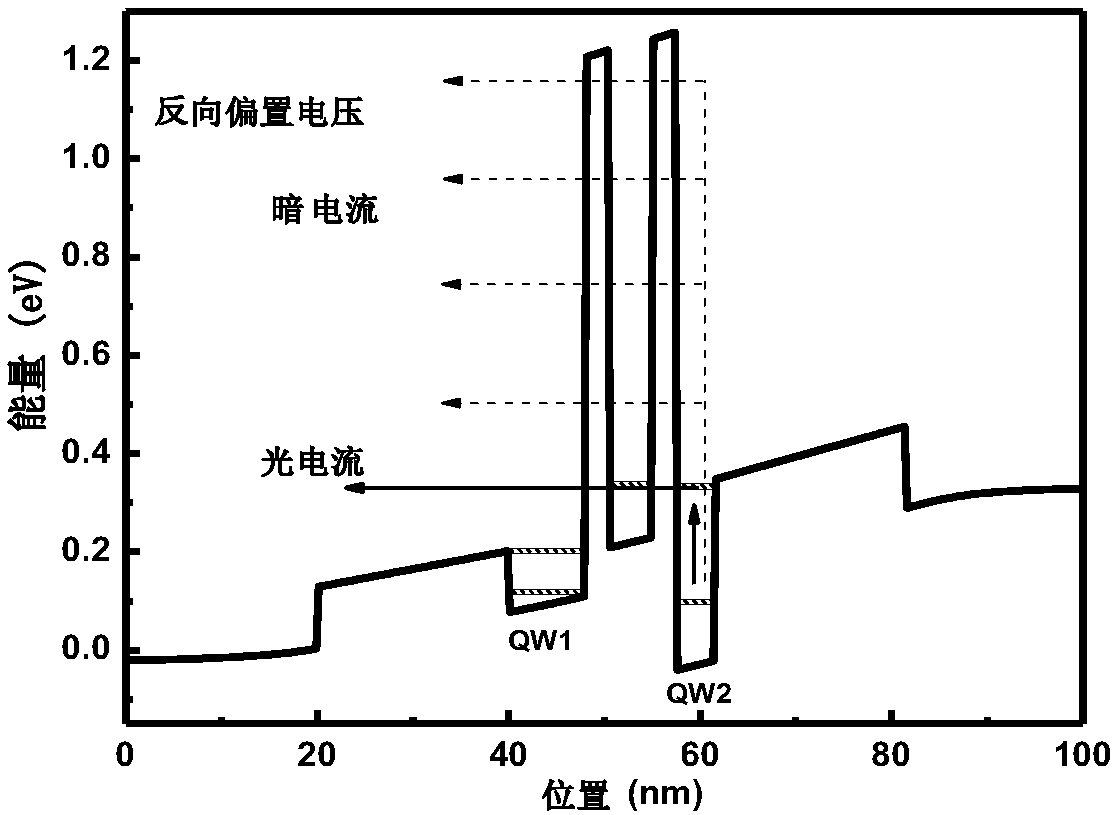

[0026] 1.1 Growth of a GaAs-based two-color quantum well material based on resonance tunneling effect with two-color detection peaks at 3 μm and 8 μm:

[0027] Using molecular beam epitaxy (MBE) to grow a buffer layer GaAs on the GaAs substrate (1), and then grow the lower electrode layer (2) GaAs:Si, the doped Si concentration is 10 17 / cm 3 , with a thickness of 0.6 μm, and the first quantum well region (3) continues to grow on the lower electrode layer (2), the structure is: barrier Al 0.27 Ga 0.73 As thickness is 40nm, potential well QW 1 The thickness is 5.2nm; QW 1 For GaAs: Si, the doping concentration is 10 17 / cm 3 . Re-grow the resonant tunneling region (4), the growth sequence of this part is: first grow a layer of AlAs barrier layer with a thickness of 2nm, and then grow a layer of 3nm tunneling potential well Al 0.25 Ga 0.75 As, finally grow a 2nm AlAs barrier layer. Continue to grow the second quantum well region (5) after the resonance tunneling region ...

specific Embodiment 2

[0031] 1.1 Growth of a GaAs-based two-color quantum well material based on resonance tunneling effect with two-color detection peaks at 5 μm and 15 μm:

[0032] Using molecular beam epitaxy (MBE) to grow a buffer layer GaAs on the GaAs substrate (1), and then grow the lower electrode layer (2) GaAs: Si, the concentration of doped Si is 5×10 17 cm -3 , with a thickness of 0.6 μm, and the first quantum well region (3) continues to grow on the lower electrode layer (2), the structure is: barrier Al 0.12 Ga 0.88 As thickness is 70nm, potential well QW 1 The thickness is 8nm; QW 1 For GaAs:Si, the doping concentration is 4×10 17 cm -3 . Re-grow the resonant tunneling region (4), the growth sequence of this part is: first grow a layer of AlAs barrier layer with a thickness of 4nm, and then grow a layer of 6nm tunneling potential well Al 0.05 Ga 0.95 As, finally grow a 4nm AlAs barrier layer. Continue to grow the second quantum well region (5) after the resonance tunneling r...

specific Embodiment 3

[0036] 1.1 Growth of a GaAs-based two-color quantum well material based on resonance tunneling effect with two-color detection peaks at 4 μm and 10.5 μm:

[0037] Using molecular beam epitaxy (MBE) to grow a buffer layer GaAs on the GaAs substrate (1), and then grow the lower electrode layer (2) GaAs:Si, the doped Si concentration is 1×10 18 cm -3 , with a thickness of 0.6 μm, and the first quantum well region (3) continues to grow on the lower electrode layer (2), the structure is: barrier Al 0.17 Ga 0.83 As thickness is 55nm, potential well QW 1 Thickness is 6nm; QW 1 For GaAs:Si, the doping concentration is 8×10 17 cm -3 . Re-grow the resonant tunneling region (4), the growth sequence of this part is: first grow a layer of AlAs barrier layer with a thickness of 3nm, and then grow a layer of 4.5nm tunneling potential well Al 0.15 Ga 0.85 As, finally grow a 3nm AlAs barrier layer. Continue to grow the second quantum well region (5) after the resonance tunneling regio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com