A kind of ultra-thin facial mask paper with high water retention and high softness and its preparation method and application

A mask paper and softening technology, applied in the field of high water retention, high softness and ultra-thin mask paper and its preparation, can solve the problems of limited ability to absorb active ingredients, not obvious improvement of wet strength, lack of data support, etc., and achieve excellent water retention and The effect of adsorption, easy operation and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

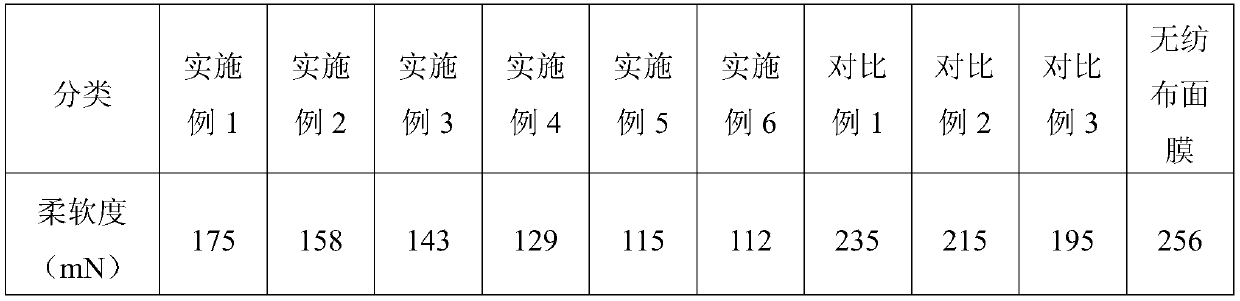

Examples

Embodiment 1

[0035] A high water retention, high softness and ultra-thin facial mask paper, the preparation method of which is as follows:

[0036] (1) Soak 100g of softwood pulp in a mixed solution (1mol / L buffer) of citric acid and sodium hydroxide with a molar ratio of 1:0.1 for 6h, and then wash with deionized water at a stirring speed of 200r / min To neutrality, add deionized water to obtain a pulp with a mass fraction of 5%.

[0037] (2) get the mass fraction that obtains in step (1) and be 20L of pulp of 5%, pulverize with ultrafine particle pulverizer (Japan Zengxing Industrial Co., Ltd., model: MKCA6-2J), and the rotating speed is 200r / min, and the gap is 20 μm , cyclically pulverized 10 times to obtain cellulose nanofibrils.

[0038] (3) Ester-based quaternary ammonium salt softening agent is added to the cellulose nanofibrils obtained in step (2), and the speed of rotation is 2000r / min, and it is uniformly decomposed, and then the decomposed slurry is paper-made to obtain a faci...

Embodiment 2

[0040] A high water retention, high softness and ultra-thin facial mask paper, the preparation method of which is as follows:

[0041] (1) Soak 100g of softwood pulp in a mixed solution (1mol / L buffer) of citric acid and sodium hydroxide molar ratio of 1:1 for 12h, the stirring speed is 1000r / min, and then wash with deionized water To neutrality, deionized water was added to obtain a pulp with a consistency of 2%.

[0042] (2) Get 20L of pulp with a mass fraction of 2% obtained in step (1), pulverize it with an ultrafine pulverizer, the rotating speed is 500r / min, the gap is 0 μm, and circulate pulverized 15 times to obtain cellulose nanofibrils.

[0043] (3) Ester-based quaternary ammonium salt softener is added to the cellulose nanofibrils obtained in step (2), and the speed of rotation is 4000r / min, and it is uniformly decomposed, and then the decomposed slurry is paper-made to obtain a facial mask Paper, wherein the softening agent accounts for 2% of the mass of cellulose...

Embodiment 3

[0045] A high water retention, high softness and ultra-thin facial mask paper, the preparation method of which is as follows:

[0046] (1) Soak 100g softwood pulp in a mixed solution (1mol / L buffer) of citric acid and sodium hydroxide molar ratio of 1:10 for 1h, stirring speed 2000r / min, then wash with deionized water until Neutral, plus deionized water to obtain a consistency of 4% pulp.

[0047] (2) Get 20L of pulp with a mass fraction of 4% obtained in step (1), pulverize it with an ultrafine pulverizer, the rotating speed is 1000r / min, the gap is -20 μm, and the circulation pulverizes 20 times to obtain cellulose nanofibrils.

[0048] (3) Ester-based quaternary ammonium salt softening agent is added to the cellulose nanofibrils obtained in step (2), and the speed of rotation is 8000r / min, and it is uniformly decomposed, and then the decomposed slurry is paper-made to obtain a facial mask Paper, wherein the softening agent accounts for 3% of the mass of cellulose nanofibri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com