Linear melt electrospinning device uniform in network formation and method

A melt electrospinning, uniform technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of large differences in the microstructure of fiber products, unstable product performance, etc., and achieve microscopic uniformity. , Improve performance and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

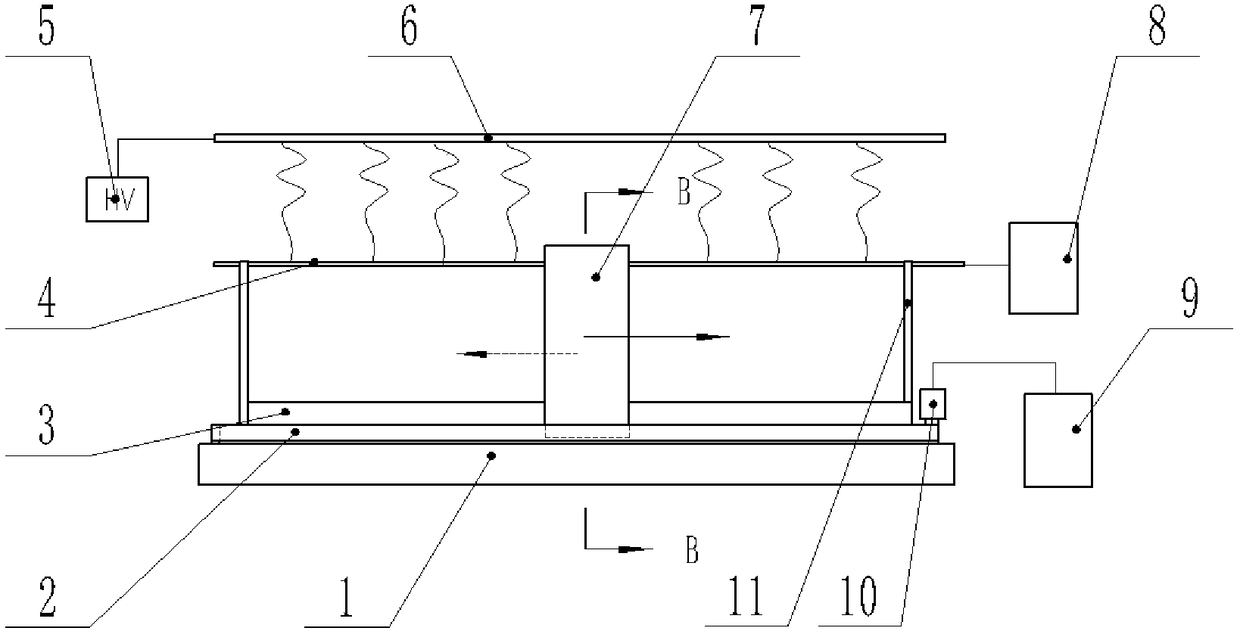

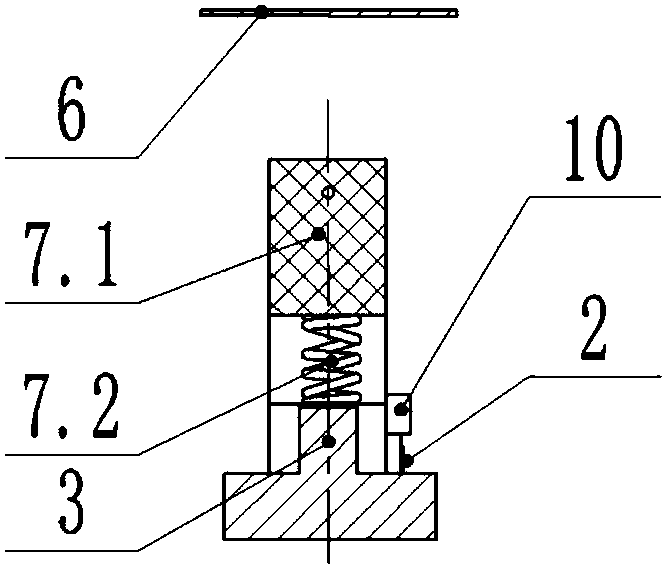

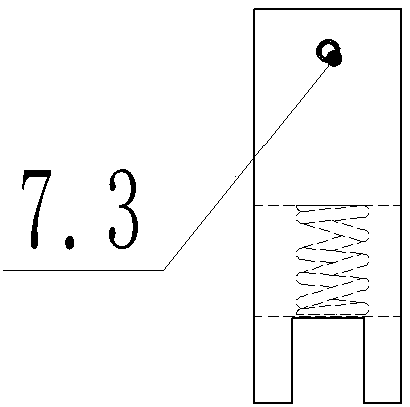

[0025] The invention proposes a linear melt electrospinning device with uniform netting. Such as Figure 1~6 As shown, the spinning device mainly includes a base 1, a traction belt 2, a guide rail 3, a spinning line 4, a high-voltage electrostatic generator 5, a receiver 6, a polymer storage 7, a heating temperature control system 8, and a control system 9 , stepper motor 10 and support column 11. The guide rail 3 , the stepper motor 10 and the support column 11 are fixed on the base 1 . Polymer reservoir 7 straddles on guide rail 3, as figure 2 and image 3 As shown, one side of the foot is fixed to the traction belt 2, and the traction belt 2 is connected to the stepper motor 10. Driven by the control system 9 and the stepper motor 10, the polymer reservoir 7 reciprocates on the guide rail 3. The spinning line 4 passes through the polymer reservoir 7, and the two ends are fixed on the support column 11. The outer surface of the spinning line 4 is grounded, and the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com