Preparation method of composite coating capable of improving high-temperature anti-oxidization performance of titanium alloy

A high-temperature anti-oxidation and composite coating technology, which is applied in the coating process and coating of metal materials, can solve the problems of poor performance of MoSi2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

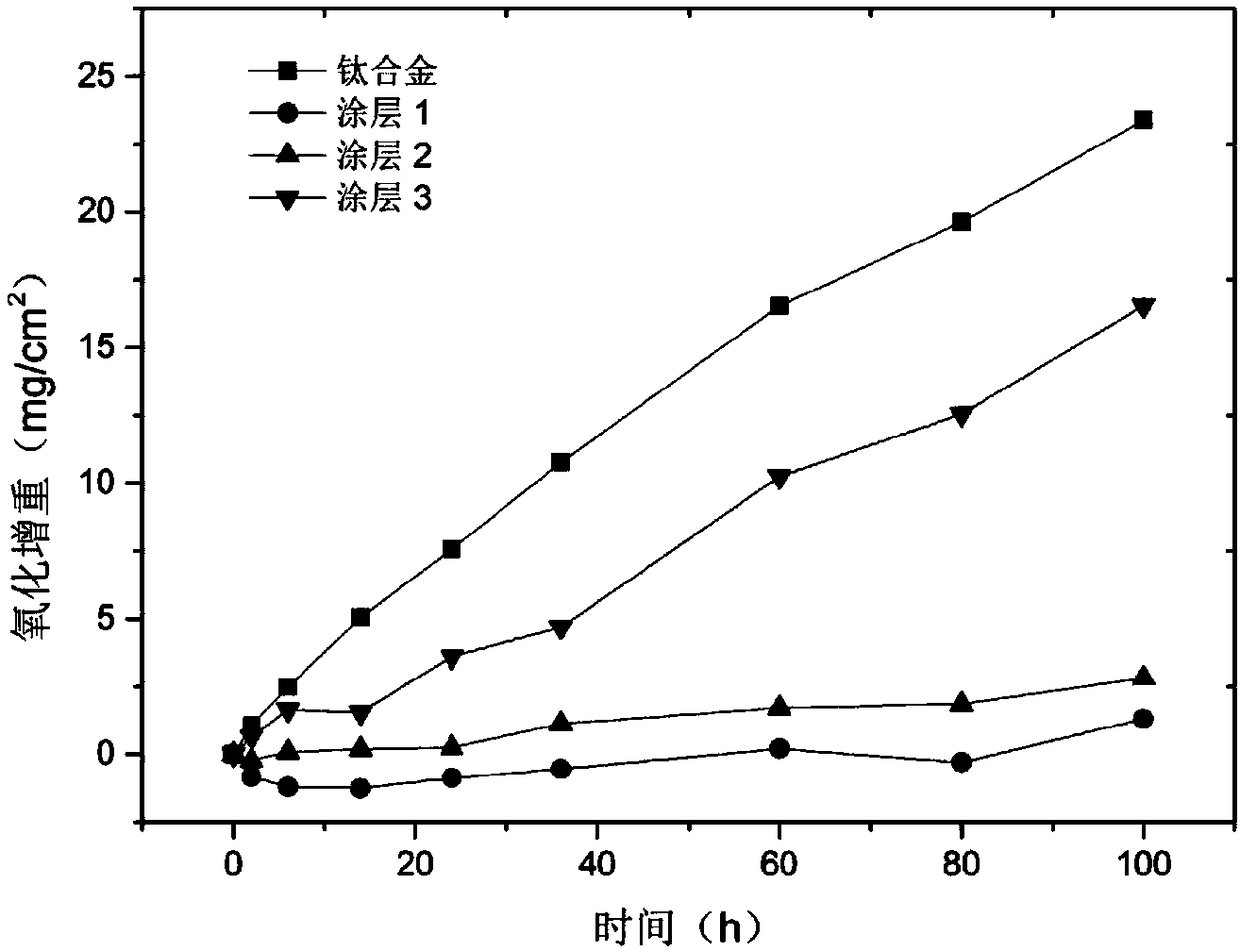

Embodiment 1

[0042] (1) Put the configured composite powder into a ball mill (QM-3SP04) for 12 hours to obtain an alloy powder mixture and dry it;

[0043] (2) Using methyl cellulose solution as the binder, the mixed alloy powder of coating 1 is pre-placed on the surface of the titanium alloy TC4 substrate with a thickness of about 1.5 mm, and the temperature is maintained in a drying oven at 120°C for 2 hours;

[0044] (3) A semiconductor laser (DLS-980.10-3000C) with an output power of 1kW is used to scan the surface of the preset alloy powder, the laser beam output rectangular spot is 6mm×6mm, and the scanning speed is 4mm / s;

[0045] (4) Using single-channel laser scanning technology to prepare high-temperature anti-oxidation composite coating.

Embodiment 2

[0047] (1) Put the configured composite powder into a ball mill (QM-3SP04) for 12 hours to obtain an alloy powder mixture and dry it;

[0048] (2) Using methyl cellulose solution as the adhesive, pre-place the mixed alloy powder of coating 2 on the surface of the titanium alloy TC4 substrate with a thickness of about 1.5 mm, and heat it in a drying oven at 120°C for 2 hours;

[0049] (3) A semiconductor laser (DLS-980.10-3000C) with an output power of 1.5kW is used to scan the surface of the preset alloy powder, the laser beam output spot is 6mm×6mm, and the scanning speed is 4mm / s;

[0050] (4) Using single-channel laser scanning technology to prepare high-temperature anti-oxidation composite coating.

Embodiment 3

[0052] (1) Put the configured composite powder into a ball mill (QM-3SP04) for 12 hours to obtain an alloy powder mixture and dry it;

[0053] (2) Using methyl cellulose solution as the binder, pre-place the mixed alloy powder of coating 3 on the surface of the titanium alloy TC4 substrate with a thickness of about 1.5 mm, and heat it in a drying oven at 120°C for 2 hours;

[0054] (3) A semiconductor laser (DLS-980.10-3000C) with an output power of 1.8kW is used to scan the surface of the prefabricated powder, and its rectangular spot is 6mm×6mm. The laser scanning speed is 4mm / s;

[0055] (4) Using single-channel laser scanning technology to prepare high-temperature anti-oxidation composite coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com