A kind of Sn-containing intermediate microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and intermediary technology, which is applied in the field of Sn-containing intermediary microwave dielectric ceramic materials and their preparation, can solve the problems of complex preparation process, difficulty in meeting development requirements for miniaturization and integration of microwave communication devices, harsh sintering conditions, and the like. Achieve the effect of simple preparation process, improved temperature coefficient of resonant frequency, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

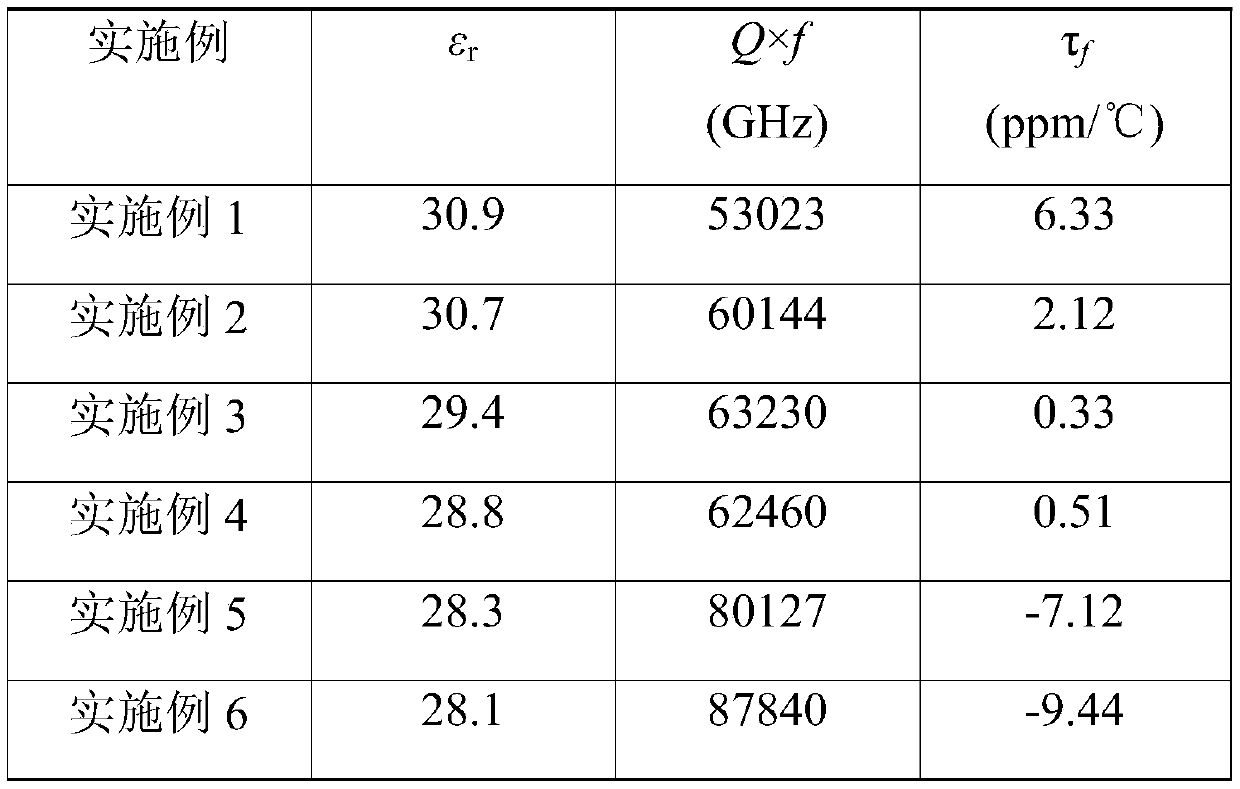

Examples

Embodiment 1

[0030] A kind of Sn-containing medium microwave dielectric ceramic material, its chemical formula is 0.58CoSnNb 2 o 8 -0.42Zn 1.01 Nb 2 o 6 .

[0031] The preparation method of the above-mentioned Sn-containing intermediate microwave dielectric ceramic material comprises the following steps:

[0032] (1) Ingredients: According to CoSnNb respectively 2 o 8 , Zn 1.01 Nb 2 o 6 Composition Weighing CoO, ZnO, Nb 2 o 5 and SnO2 ; Among them, CoO, ZnO, Nb 2 o 5 and SnO 2 The purity is greater than 99.9%;

[0033] (2) Ball milling: with ethanol as the medium, the raw materials in step (1) are mixed by ball milling to obtain a slurry; wherein, the weight ratio of the raw materials in step (1) to ethanol is 1:1, and the ball milling speed is 300r / h min, ball milling time is 7h;

[0034] (3) Calcination synthesis: after drying, grinding and sieving the slurry obtained in step (2), calcining at 1100°C and 1000°C for 4h respectively to obtain CoSnNb 2 o 8 and Zn 1.01 Nb ...

Embodiment 2

[0041] A kind of Sn-containing medium microwave dielectric ceramic material, its chemical formula is 0.57CoSnNb 2 o 8 -0.43Zn 1.01 Nb 2 o 6 .

[0042] The preparation method of the above-mentioned Sn-containing intermediate microwave dielectric ceramic material comprises the following steps:

[0043] (1) Ingredients: According to CoSnNb respectively 2 o 8 , Zn 1.01 Nb 2 o 6 Composition Weighing CoO, ZnO, Nb 2 o 5 and SnO 2 ; Among them, CoO, ZnO, Nb 2 o 5 and SnO 2 The purity is greater than 99.9%;

[0044] (2) Ball milling: with ethanol as the medium, the raw materials in step (1) are mixed by ball milling to obtain slurry; wherein, the weight ratio of raw materials in step (1) to ethanol is 1:1, and the ball milling speed is 400r / h min, ball milling time is 5h;

[0045] (3) Calcination synthesis: after drying, grinding and sieving the slurry obtained in step (2), calcining at 1100°C and 1000°C for 4h respectively to obtain CoSnNb 2 o 8 and Zn 1.01 Nb 2 o...

Embodiment 3

[0052] A kind of Sn-containing medium microwave dielectric ceramic material, its chemical formula is 0.52CoSnNb 2 o 8 -0.48Zn 1.01 Nb 2 o 6 .

[0053] The preparation method of the above-mentioned Sn-containing intermediate microwave dielectric ceramic material comprises the following steps:

[0054] (1) Ingredients: According to CoSnNb respectively 2 o 8 , Zn 1.01 Nb 2 o 6 Composition Weighing CoO, ZnO, Nb 2 o 5 and SnO 2 ; Among them, CoO, ZnO, Nb 2 o 5 and SnO 2 The purity is greater than 99.9%;

[0055] (2) Ball milling: with ethanol as the medium, the raw materials in step (1) are mixed by ball milling to obtain slurry; wherein, the weight ratio of raw materials in step (1) and ethanol is 1:1, and the ball milling speed is 350r / h min, ball milling time is 6h;

[0056] (3) Calcination synthesis: after drying, grinding and sieving the slurry obtained in step (2), calcining at 1100°C and 1000°C for 4h respectively to obtain CoSnNb 2 o 8 and Zn 1.01 Nb 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com