Multilayered co-extruded low-temperature polyolefin crosslinked heat shrinking film and preparation method thereof

A heat-shrinkable film and multi-layer co-extrusion technology, which is applied in the direction of chemical instruments and methods, layered products, flat products, etc., can solve the problems of inability to meet special packaging requirements, high film thickness, and small improvement in mechanical properties, and achieve maintenance Dimensional stability, low shrinkage temperature, and the effect of meeting packaging needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

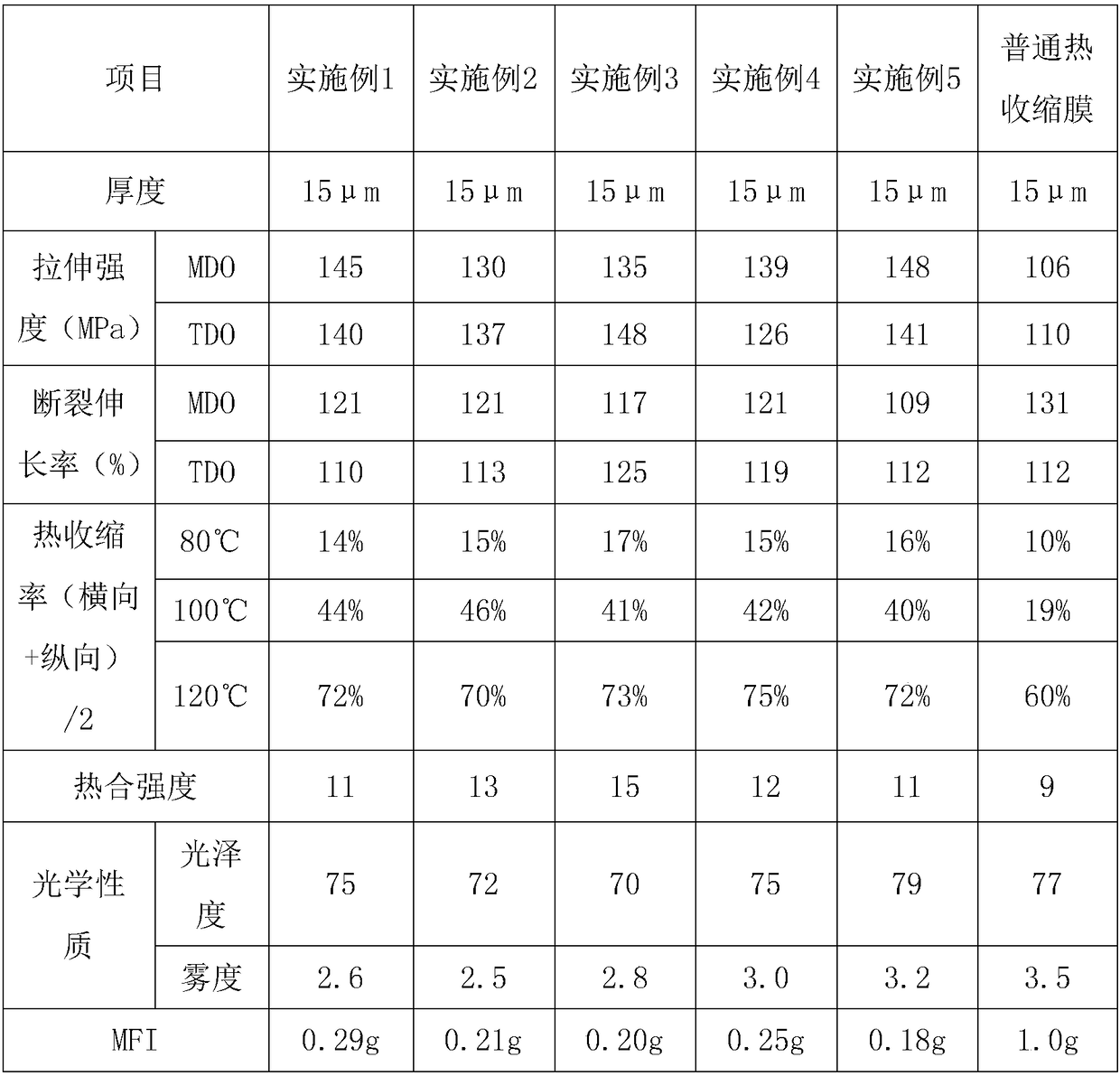

Examples

Embodiment 1

[0031] A multi-layer co-extruded low-temperature polyolefin cross-linked heat-shrinkable film, the heat-shrinkable film is composed of three layers of co-extruded and bonded films, namely an outer layer, a middle layer and an inner layer;

[0032] The outer layer is composed of FP120 of NOVA Chemicals with a mass fraction of 15%, Dow Chemical 2036 with a mass fraction of 81%, and ABPP905 of 4%.

[0033] The middle layer is composed of 97% Dow Chemical 2256, 3% oleic acid amide by weight percentage,

[0034] The inner layer has the same composition as the outer layer,

[0035] Wherein, the ratio of the thickness of the outer layer: the thickness of the middle layer: the thickness of the inner layer is 1:4:1.

[0036] A method for preparing a multilayer co-extruded low-temperature polyolefin cross-linked heat-shrinkable film, comprising the following steps:

[0037] (1) Extrusion molding: the raw materials of the outer layer, the middle layer, and the inner layer are mixed uni...

Embodiment 2

[0044] A multi-layer co-extruded low-temperature polyolefin cross-linked heat-shrinkable film, the low-temperature polyolefin heat-shrinkable cross-linked film is composed of three layers of co-extruded and bonded films, namely an outer layer, a middle layer and an inner layer;

[0045] The outer layer is composed of 40% Dow Chemical 2045, 56% Dow 4023, 4% ABPP905 by mass fraction,

[0046] The middle layer is composed of 47% Dow Chemical 2256 by weight, 50% Dow Chemical 4023 by weight, and 3% oleic acid amide,

[0047] The inner layer has the same composition as the outer layer,

[0048] Wherein, the ratio of the thickness of the outer layer: the thickness of the middle layer: the thickness of the inner layer is 1:4:1.

[0049] A film-making process of low-temperature crosslinked polyolefin heat-shrinkable film, comprising the following steps:

[0050] (1) Extrusion molding: the raw materials of the outer layer, the middle layer, and the inner layer are mixed uniformly by w...

Embodiment 3

[0057] A multi-layer co-extruded low-temperature polyolefin cross-linked heat-shrinkable film, the low-temperature polyolefin heat-shrinkable cross-linked film is composed of three layers of co-extruded and bonded films, namely an outer layer, a middle layer and an inner layer;

[0058] The outer layer is composed of 20% Yanshan Petrochemical 1I2A, 20% 2036, 4% ABPP906,

[0059] The middle layer is composed of 15% by weight of FP120 of NOVA Chemicals, 82% of Shanghai Petrochemical 2426H, and 3% of silicone,

[0060] The inner layer has the same composition as the outer layer,

[0061] Wherein, the ratio of the thickness of the outer layer: the thickness of the middle layer: the thickness of the inner layer is 1:6:1.

[0062] A method for preparing a multilayer co-extruded low-temperature polyolefin cross-linked heat-shrinkable film, comprising the following steps:

[0063] (1) Extrusion molding: Mix the three layers of raw materials evenly according to the weight percentage,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com