UV primer paint spraying line

A paint spraying line and primer technology, applied in spray booths, spraying devices, pre-treated surfaces, etc., can solve the problems of blocked pipes, reduce work efficiency, waste, etc., and achieve the effects of easy reuse, wide application range, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

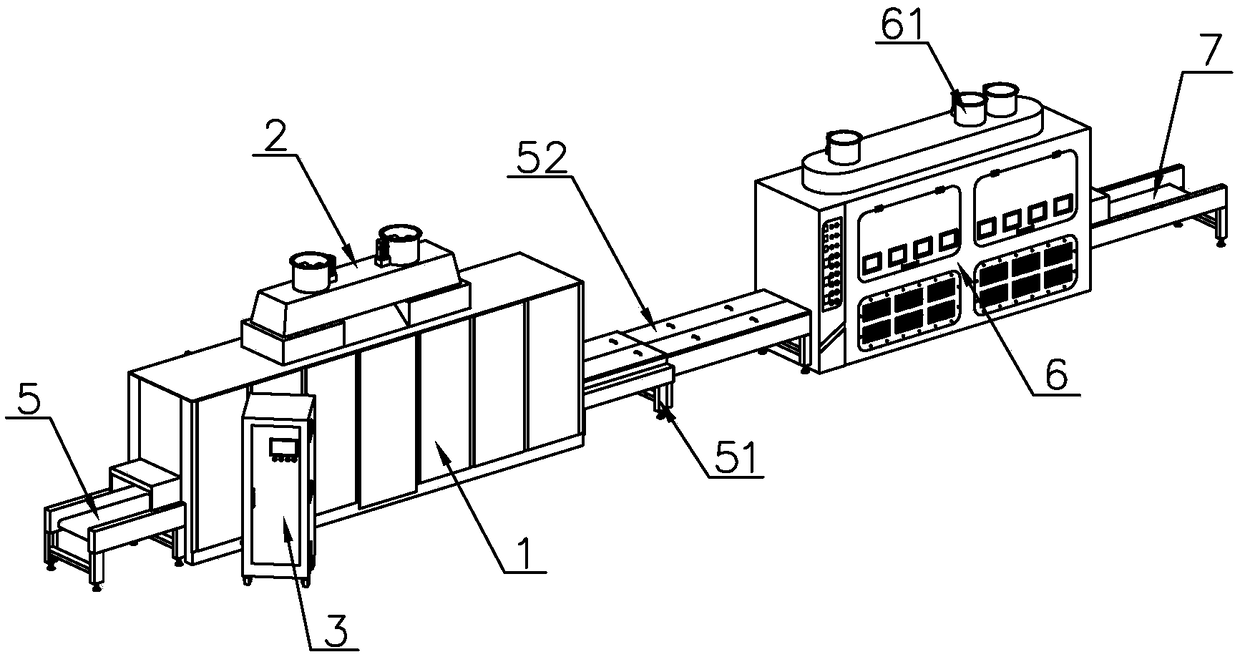

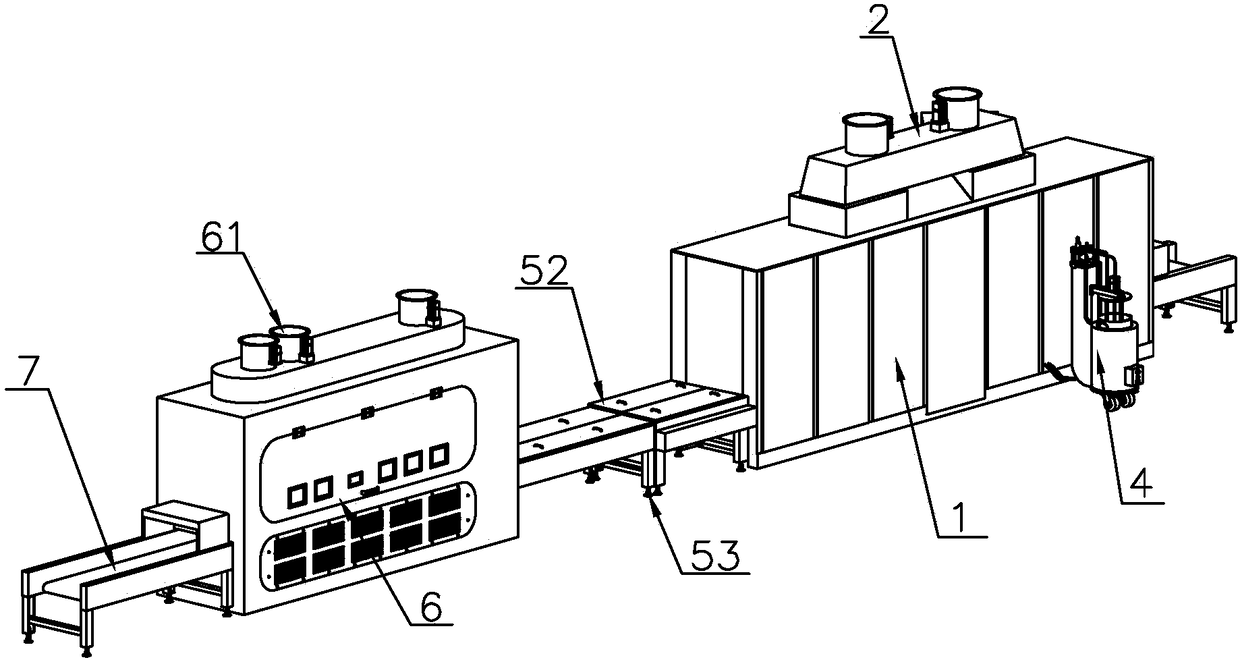

[0047] Such as Figure 1-13 As shown, a UV primer painting line includes a painting device 1, a negative pressure device 2, a control cabinet 3, a conveyor belt I5, a drying device 6, and a conveyor belt II7. There is a control cabinet 3 on one side of the device 2, and a lifting mechanism 8 and a gun bag 9 are arranged inside the painting device 1. The lifting mechanism 8 drives the gun bag 9 to adjust the height, and the workpiece is sprayed with UV paint through the gun bag 9. The painting device 1 is two There is a conveyor belt I5 at the end, and a drying device 6 is installed on one side of the conveyor belt I5, and a conveyor belt II7 is arranged in the drying device 6, and the conveyor belt II7 extends to both sides of the drying device 6, and the workpiece is transported by the conveyor belt I5 to the paint spraying device 1. For the spraying of UV paint, the scattered paint mist is discharged through the negative pressure device. After the spraying is completed, the ...

Embodiment 2

[0056] Such as Figure 7 As shown, the difference from Embodiment 1 is that a connecting plate 810 is provided below the gun bag 9, and a wind direction guide plate 811 is provided on the inside of the connecting plate 810. One end of the wind direction guide plate 811 is installed on the connecting plate 810 through a pin shaft, and the wind direction guides The other end of the plate 811 is overlapped in the groove at the bottom of the baffle plate 102. When the gun bag 9 moves up and down, the gun bag 9 drives the wind direction guide plate 811 to move through the connecting plate 810 to adjust the angle of the wind direction guide plate 811. The angle of the plate 811, and then adjust the wind direction, to ensure that the paint mist will not stay too much at the spray gun I903 and pollute the spray gun I903.

Embodiment 3

[0058] Such as Figure 14 As shown, different from Embodiment 1, the bottom of the gun bag 9 is provided with a scraping mechanism, and the scraping mechanism includes a brush plate 905, a motor II 906, a steel belt machine I 907, a photoelectric sensor II 908, and the motor II 906 is set At one end of the placement frame 901, a steel belt machine I907 is arranged on one side of the motor II906, and the steel belt machine I907 is set inside the bottom of the placement frame 901. A brush plate 905 is provided on the steel belt machine I907, and a photoelectric sensor is installed at the other end of the placement frame 901. Ⅱ908, after the spraying of the workpiece by the gun package 9, the motor Ⅱ906 drives the steel belt machine Ⅰ907 to make the brush plate 905 scrape the spray gun Ⅰ903 and the gun frame Ⅰ902 to prevent UV paint droplets remaining on the spray gun Ⅰ903 and the gun frame Ⅰ902 onto the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com