A kind of vertical structure LED chip of double insertion layer reflector structure and preparation method thereof

A LED chip and vertical structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor thermal stability and poor adhesion of Ag-based reflectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

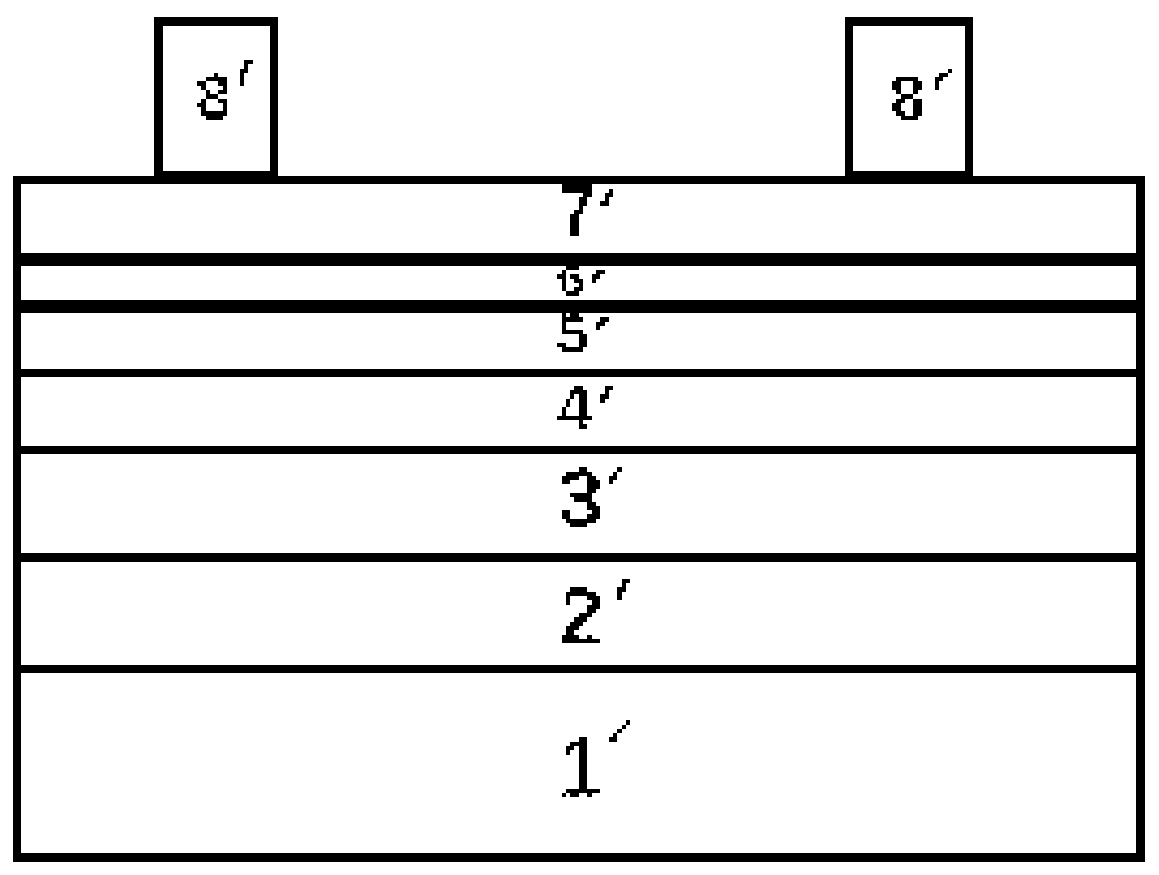

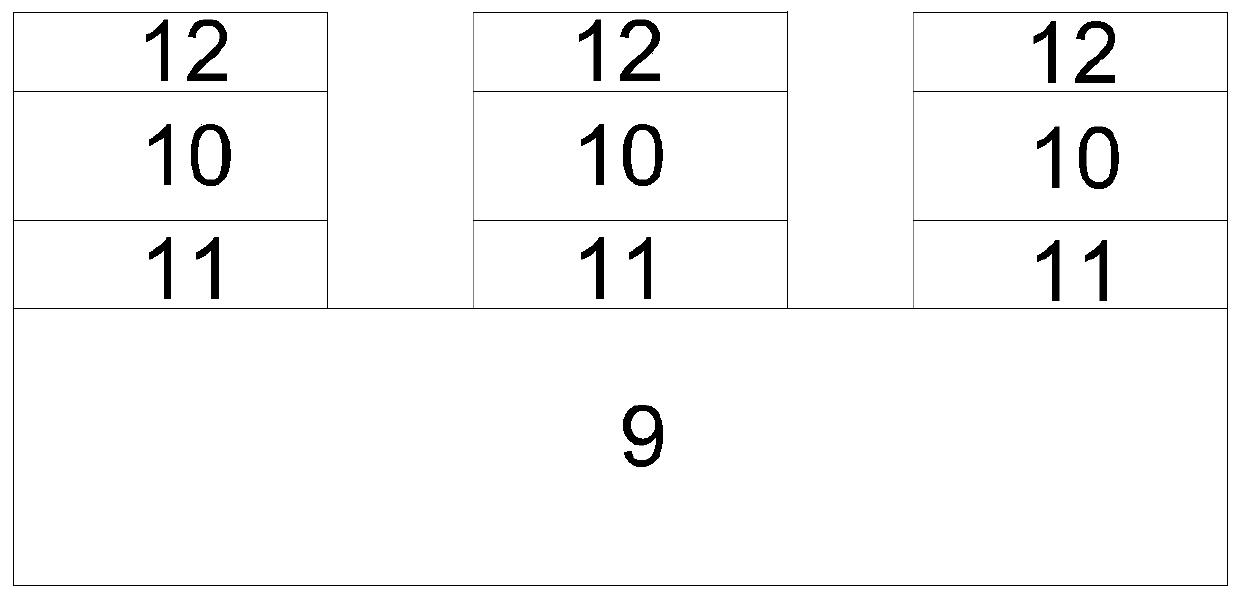

[0073] refer to Figure 3-1 , a vertical structure LED chip with double insertion layer reflector structure, its preparation method comprises,

[0074] LED epitaxial wafer growth: first epitaxially grow LED epitaxial wafer 9' on Si substrate, including n-type doped GaN film grown on Si substrate, InGaN / GaN quantum well grown on n-type doped GaN film and The p-type doped GaN thin film grown on the InGaN / GaN quantum well; the Si substrate takes the (111) plane as the epitaxial plane; the thickness of the n-type doped GaN layer is 2 μm; the InGaN / GaN quantum well 8 cycles of InGaN well layer / GaN barrier layer, wherein the thickness of InGaN is 4nm, the thickness of GaN barrier layer is 12nm; the thickness of the p-type doped GaN film is 200nm; the first step of inserting the metal layer into the growth mirror : Electron beam evaporation, magnetron sputtering or thermal evaporation equipment is used on the surface of the LED epitaxial wafer, and the first layer of the evaporation...

Embodiment 2

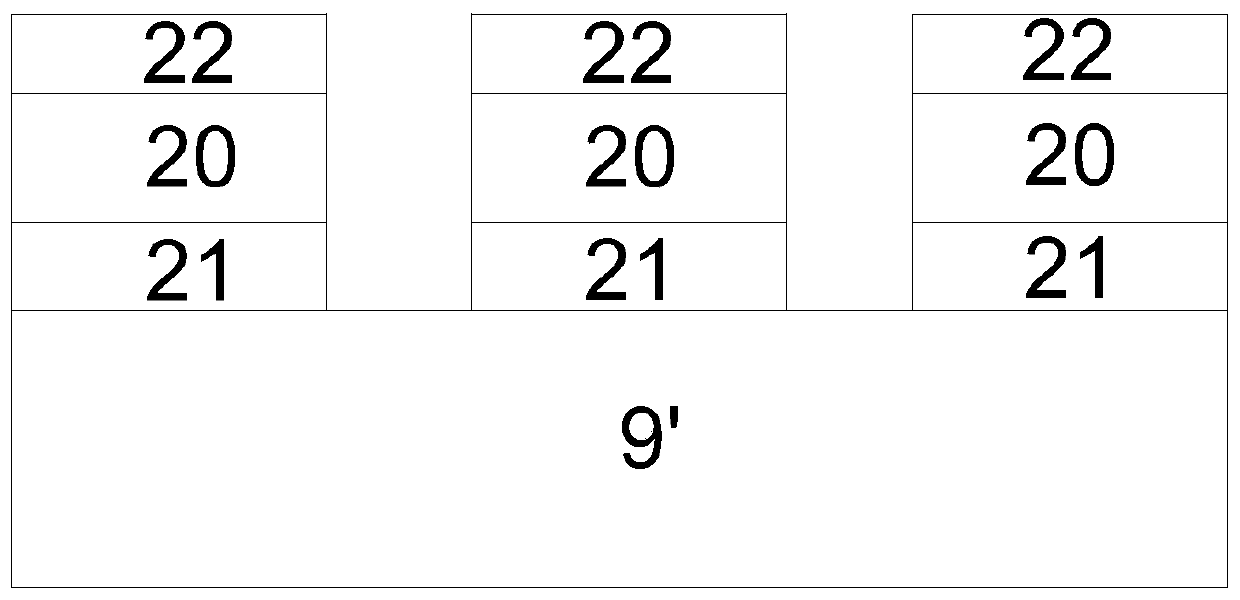

[0081] refer to Pic 4-1 , a vertical structure LED chip with double insertion layer reflector structure, its preparation method comprises,

[0082] LED epitaxial wafer growth steps: first epitaxially grow LED epitaxial wafer 9" on Si substrate, LED epitaxial wafer 9" includes n-type doped GaN thin film grown on Si substrate, n-type doped GaN thin film grown on n-type doped GaN thin film InGaN / GaN quantum wells and p-type doped GaN films grown on InGaN / GaN quantum wells; the Si substrate takes the (111) plane as the epitaxial plane; the thickness of the n-type doped GaN layer is 2 μm; The InGaN / GaN quantum well is an InGaN well layer / GaN barrier layer with 8 periods, wherein the thickness of InGaN is 4nm, and the thickness of the GaN barrier layer is 12nm; the thickness of the p-type doped GaN film is 200nm;

[0083] The step of growing the reflector first inserting the metal layer: using electron beam evaporation, magnetron sputtering or thermal evaporation equipment on the ...

Embodiment 3

[0090] A vertical structure LED chip with a double-insertion layer reflector structure, the preparation method of which comprises,

[0091] LED epitaxial wafer growth steps: first grow LED epitaxial wafers on Si substrates, LED epitaxial wafers include n-type doped GaN films grown on Si substrates, grow InGaN / GaN quantum wells on n-type doped GaN films and A p-type doped GaN thin film is grown on the InGaN / GaN quantum well; the Si substrate takes the (111) plane as an epitaxial plane; the thickness of the n-type doped GaN layer is 1 μm; the InGaN / GaN quantum well is 4 periods of InGaN well layer / GaN barrier layer, wherein the thickness of InGaN is 7nm, the thickness of GaN barrier layer is 3nm; the thickness of the p-type doped GaN film is 100nm;

[0092] The first step of inserting the metal layer of the growing reflector: using electron beam evaporation, magnetron sputtering or thermal evaporation equipment on the surface of the LED epitaxial wafer, and evaporating the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com