Method for measuring impurity elements aluminum, phosphor and titanium in nickel concentrate ores

A technology of impurity elements and concentrates, applied in the field of determination of impurity elements aluminum, titanium, and phosphorus in nickel concentrates, can solve the problems of difficult analysis of large quantities of samples, expensive instruments, and limited number of digested samples, etc., to achieve the analysis cycle. Short, strong anti-matrix interference, good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

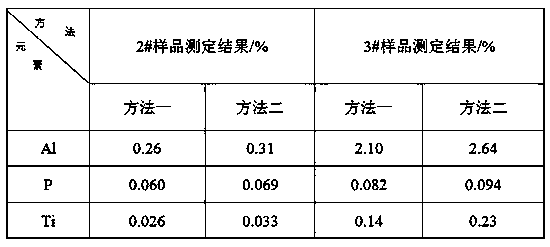

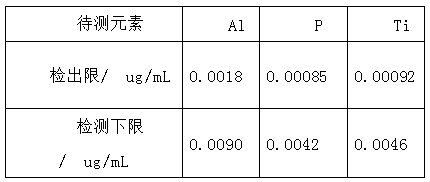

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with specific embodiments.

[0024] 1, the present invention uses reagent and instrument measurement parameter in assay process to have:

[0025] (1) Reagent preparation:

[0026] 1.1. Hydrochloric acid: ρ1.19g / mL, superior grade.

[0027] 1.2. Nitric acid: ρ1.42g / mL, superior grade.

[0028] 1.3. Hydrofluoric acid: ρ1.16g / mL.

[0029] 1.4. Perchloric acid: ρ1.67g / mL.

[0030] 1.5. Hydrochloric acid (1+1): The preparation method is to pipette 50mL of the above-mentioned high-grade pure hydrochloric acid into a 100mL beaker with 50mL of water and mix well.

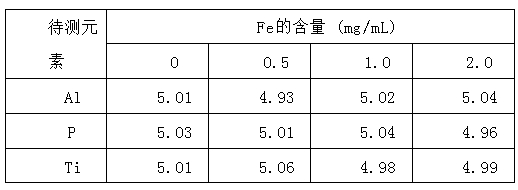

[0031] 1.6. Iron matrix solution (30mg / mL): Weigh 4.285 g of ferric oxide standard into a 250 mL beaker, add 25 mL of hydrochloric acid, cover with a watch glass, heat and dissolve on a hot plate at low temperature, cool, transfer to 100 mL In a volumetric flask, dilute to the mark with water and mix well.

[0032] 1.7, 1000ug / mL standard al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com