A Method for Preparation of Ceramic Particle Reinforced Metal Matrix Composites by Microwave-Ultrasonic Coupling

A ceramic particle and ultrasonic coupling technology, which is applied in the field of microwave-ultrasonic coupling to prepare ceramic particle-reinforced metal matrix composites, can solve the problem that casting technology is difficult to realize the compounding of metals and particles with poor specific gravity, and powder metallurgy technology has a long molding cycle and cannot be upgraded. To the temperature required for the reaction and other issues, to achieve the effect of improving the interface binding mode, improving the interface binding mode, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

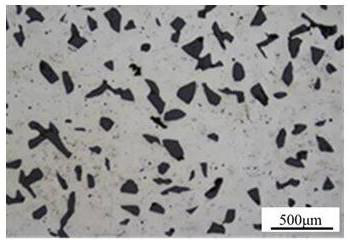

Image

Examples

Embodiment 1

[0023] A method for preparing a zirconia-toughened alumina (ZTA) ceramic particle-reinforced high-chromium cast iron-based composite material by microwave-ultrasonic coupling, the specific steps are as follows:

[0024] (1) Mix ZTA particles with Cr23 high-chromium cast iron powder chips at a mass ratio of 1:1, and add silicone resin accounting for 6% of the total mass of ceramic particles and metal powder chips, mix evenly, and put them into a glass crucible, in which ZTA The particle size of the particles is 0.1~0.3mm, and the Cr23 high chromium cast iron chips are passed through a 48-mesh sieve before adding;

[0025] (2) Put the glass crucible in the microwave resonant cavity, heat it with 5KW microwave for 4 minutes to melt the metal powder, and turn on the ultrasonic device under the action of continuous microwave. The ultrasonic parameters are: the frequency of ultrasonic is 30kHz, and the intensity is 6W / cm 2 , ultrasonic 5min;

[0026] (3) Turn off the microwave, i...

Embodiment 2

[0029] Preparation of alumina (Al 2 o 3 ) and zirconia (ZrO 2 ) The method for ceramic particle reinforced high manganese steel matrix composite material, concrete steps are as follows:

[0030] (1) Alumina (Al 2 o 3 ) and zirconia (ZrO 2 ) particles are mixed according to the mass ratio of 1:1, the Al 2 o 3 and ZrO 2 Mixed ceramic particles and Mn13Cr2 high manganese steel chips are mixed at a mass ratio of 0.08:1, and epoxy resin accounting for 5% of the total mass of mixed ceramic particles and high manganese steel chips is added, mixed evenly, and put into a ceramic crucible, wherein Al 2 o 3 and ZrO 2 The particle size of the particles is 0.3~0.6mm, and the Mn13Cr2 high manganese steel chips are passed through a 48-mesh sieve before adding;

[0031] (2) Place the ceramic crucible in the microwave resonant cavity, heat it with 1KW microwave for 8 minutes to melt the metal powder, and turn on the ultrasonic device under the action of continuous microwave. The ultr...

Embodiment 3

[0034] Preparation of alumina (Al 2 o 3 ), zirconia (ZrO 2 ) and zirconia toughened alumina (ZTA) particles to reinforce the method for aluminum-silicon alloy-based composite materials, the specific steps are as follows:

[0035] (1) Alumina (Al 2 o 3 ), zirconia (ZrO 2 ) and zirconia toughened alumina (ZTA) particles are mixed according to the mass ratio of 1:1:1, the Al 2 o 3 , ZrO 2 Mix with ZTA mixed ceramic particles and A356 aluminum-silicon alloy powder chips at a mass ratio of 0.05:1, and add acrylic resin accounting for 4% of the total mass of the mixed ceramic particles and A356 aluminum-silicon alloy powder chips, mix evenly, and put it in a glass crucible. where Al 2 o 3 , ZrO 2 And the particle size of ZTA particles is 0.6~1mm, and the A356 aluminum-silicon alloy chips are passed through a 48-mesh sieve before adding;

[0036] (2) Put the glass crucible in the microwave resonant cavity, heat it with 10KW microwave for 1min to melt the metal shavings, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com