A kind of method for preparing high cetane diesel oil by direct hydrogenation of animal and vegetable fats and oils

A technology of animal and vegetable oil and high cetane, which is applied in the field of direct hydrogenation of animal and vegetable oil to prepare high cetane number diesel, can solve the problems of low product yield, low grade, easy deactivation of catalyst and economic benefits, etc. The effect of high catalyst activity, reduction of cold filter point and density, good economic benefits and industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

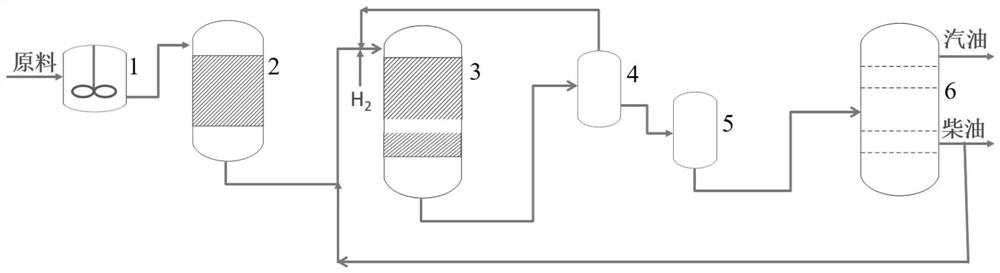

Method used

Image

Examples

Embodiment 1

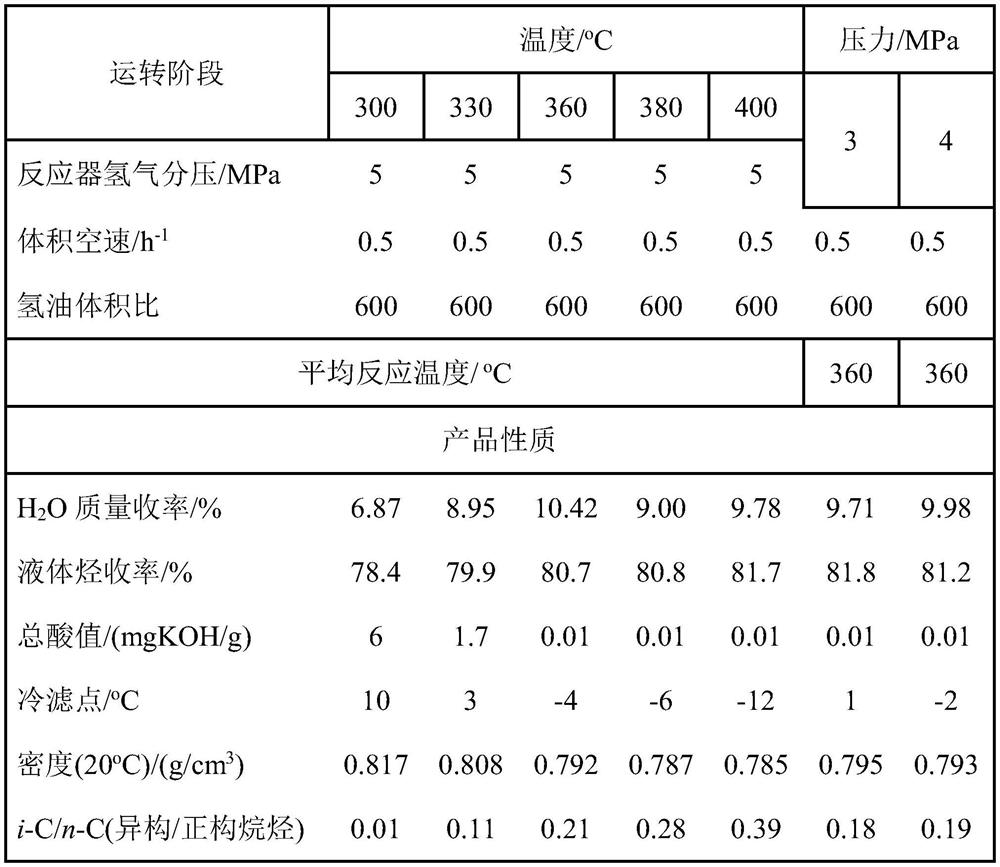

[0024] Embodiment 1: With water content as 2%, the palm oil press that metal ion content is 500ppm, and total acid value is 160mgKOH / g is raw material, and water content can be reduced to below 0.2% through flashing, with humic acid substance and The mixed molding of clay is an adsorbent, and the reaction conditions are: temperature 100°C, space velocity 0.2h -1 , wherein the humic acid substances account for 30% of the total mass, and the clay mass accounts for 70% of the total mass. After passing through the adsorption bed, the metal ion concentration in the raw material is reduced to 20ppm. SiO 2 -Al 2 o 3 Supported fluorine and lanthanum modified NiMo sulfide catalysts as refined catalysts with certain isomeric functions, in which NiO accounts for 4%, MoO 3 It accounts for 22%, La accounts for 2%, F accounts for 0.5%, and the rest is carrier; the supplementary refined catalyst is an oxide-supported NiW sulfide catalyst. Based on the mass of the catalyst before presulfu...

Embodiment 2

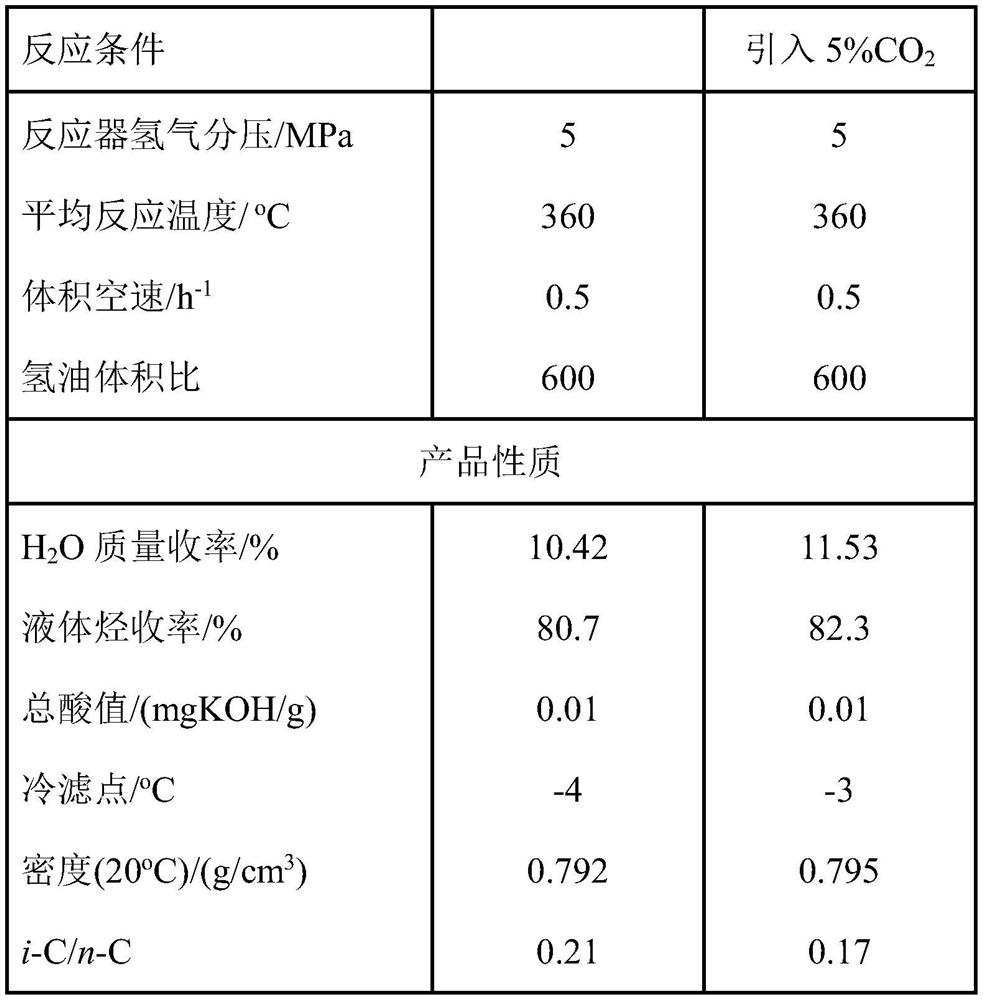

[0027] Embodiment 2: with SiO 2 -Al 2 o 3Supported fluorine and lanthanum modified NiMo sulfide catalysts as refined catalysts with certain isomeric functions, in which NiO accounts for 4%, MoO 3 It accounts for 22%, La accounts for 2%, F accounts for 0.5%, and the rest is carrier; the supplementary refined catalyst is an oxide-supported NiW sulfide catalyst. Based on the mass of the catalyst before presulfurization, NiO accounted for 6%, WO 3 15% and the rest is Al 2 o 3 Carrier; the volume ratio of the loaded refined catalyst to the added refined catalyst is 5:1. Reaction conditions: temperature 360°C, hydrogen partial pressure 5MPa, space velocity 0.5h -1 , under the condition of hydrogen-to-oil ratio of 600, self-produced diesel oil is used as circulating oil, and the mass ratio of circulating oil to raw oil is 1:1 as feed for hydrorefining. See Table 2 below for supplemental CO 2 influence on the outcome of the reaction.

[0028]

[0029] It can be seen from t...

Embodiment 3

[0030] Embodiment 3: with SiO 2 -Al 2 o 3 Supported fluorine and lanthanum modified NiMo sulfide catalysts as refined catalysts with certain isomeric functions, in which NiO accounts for 4%, MoO 3 It accounts for 22%, La accounts for 2%, F accounts for 0.5%, and the rest is carrier; the supplementary refined catalyst is an oxide-supported NiW sulfide catalyst. Based on the mass of the catalyst before presulfurization, NiO accounted for 6%, WO 3 15% and the rest is Al 2 o 3 Carrier; the volume ratio of the loaded refined catalyst to the added refined catalyst is 5:1. Reaction conditions: temperature 360°C, hydrogen partial pressure 5MPa, space velocity 0.5h -1 , under the condition of hydrogen-to-oil ratio 600, self-produced diesel oil is used as the circulating oil, and the influence of the reaction results is shown in Table 3 below when the mass ratio of the circulating oil to the feedstock oil is different.

[0031]

[0032] It can be seen from the table that when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com