Channeling sealing plugging agent for oilfield

A plugging agent and oil field technology, applied in the field of high pressure plugging of leakage plugging agent, multi-layer plugging and corroded casing leakage in oilfield, which can solve the problem of low success rate, short validity period, unable to plug the plugging strength, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: XX well-water channeling well;

[0020] The production layer of this well is 6 layers long, the well depth is 2424.0m, the artificial well bottom is 2400.6m, and the formation salinity is 8.2×104mg / l. The qualified well section went down to the oil layer, causing the water cut to rise rapidly, and the water cut was 100%, so the well was forced to be shut down.

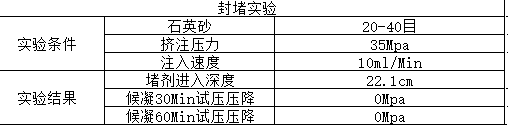

[0021] On-site preparation 25m 3 Channeling sealing agent, the composition ratio of the channeling sealing agent is shown in Table 1, the construction process of circulating channeling is adopted, the plugging agent is pushed into the channeling channel, the drill is pulled out to a safe position, after the well is washed, the well is shut down and pressed 28MP, Hou Ning 72 hours. After the plug was drilled, the pressure test was 24MPa and passed. After operation, the daily liquid production is 3.3 tons, the daily oil production is 1.98 tons, and the water content is 28.5%.

[0022] Table 1 Pro...

Embodiment 2

[0024] Embodiment 2: XX well-casing leaky well;

[0025] The production layer of this well is 4+5 layers long, the well depth is 2329.0m, the artificial well bottom is 2383.0m, and the formation salinity is 8.0×104mg / l. In July 2015, the pump did not produce fluid, and the pump (sand stuck) occurred. Casing damage was found during the pump inspection operation. It was preliminarily judged on site that there was casing damage between 2200.63m and 2205.00m, and a large amount of sand was produced in the formation.

[0026] First of all, during the leak detection operation, serious casing damage was found in the 2269-2273.5m well section.

[0027] Then, the sealing was carried out in three times, and 56 square meters of sealing agent were shared. After drilling the plug, the 22MPa pressure test is qualified. After operation, the daily liquid production is 3.26 tons, the daily oil production is 2.29 tons, and the water content is 29.8%. See Table 2 for the distribution ratio of...

Embodiment 3

[0031] XX well-casing leaky well;

[0032] The production layer of the well is 6 layers long, the well depth is 2368.2m, the artificial well bottom is 2311.6m, and the formation salinity is 8.0×104mg / l. Casing damage exists between 1620.5 and 1910.00m in the judgment well section.

[0033] First of all, during the leak detection operation, serious casing damage was found in the 1782.3-1785.1 and 1896.1-1898.7 well sections.

[0034] Then, prepare 40m on site 3 The plugging agent was used for plugging in two times, the first plugging: 1896.1-1898.7 well section, the second plugging: 1782.3-1785.1 well section; the shut-in pressure was 26.5MP, and the waiting time was 72 hours. After drilling the plug, the pressure test was 23.5MPa and passed. After operation, the daily liquid production is 2.89 tons, the daily oil production is 1.1 tons, and the water content is 39.2%. See Table 3 for the distribution ratio of each component of the channeling and leakage sealing agent used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com