Modified calcium carbonate filled PVC tubular product and preparation method thereof

A PVC pipe, calcium carbonate technology, applied in pipeline protection, mechanical equipment, pipeline damage/wear prevention, etc., can solve problems such as poor adhesion between the matrix and filler interface, low mechanical strength of PVC pipes, and shortened pipe service life. , to achieve the effect of good stability, not easy to deform, and improve the notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

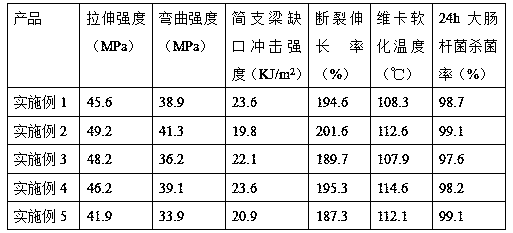

Examples

Embodiment 1

[0034] A modified calcium carbonate filled PVC pipe, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 8 parts of bismaleimide, 3 parts of acrylic acid-maleic anhydride copolymer, polyaminopropylmethyl sesqui 2.5 parts of siloxane, 1.5 parts of castor oil maleate, 25 parts of modified nano calcium carbonate, 4 parts of asbestos fiber, 2.5 parts of coupling agent, 1 part of crosslinking agent, 1 part of 1010 antioxidant, organic tin stabilizer 1.2 parts, 1.5 parts of antibacterial agent and 4 parts of processing aid.

[0035] The preparation of described modified calcium carbonate comprises the steps:

[0036] (1) Put quicklime and 60°C hot water into the digestion reactor according to the mass ratio of 1:5 to carry out digestion reaction, remove impurities, stand and age for 48 hours, and dilute to a specific gravity of 1.060 to obtain lime emulsion;

[0037] (2) Transport the lime emulsion to the carbonation reaction tower, feed carbon dioxid...

Embodiment 2

[0046] A modified calcium carbonate filled PVC pipe, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 6 parts of bismaleimide, 4 parts of acrylic acid-maleic anhydride copolymer, polyaminopropylmethyl sesqui 1.5 parts of siloxane, 1 part of castor oil maleate, 20 parts of modified nano calcium carbonate, 3 parts of asbestos fiber, 1 part of coupling agent, 1.5 parts of crosslinking agent, 1.5 parts of 1076 antioxidant, organic tin stabilizer 0.8 parts, 2 parts of antibacterial agent and 3.5 parts of processing aid.

[0047] The preparation of described modified calcium carbonate comprises the steps:

[0048] (1) Put quicklime and 70°C hot water into the digestion reactor according to the mass ratio of 1:4 to carry out digestion reaction, remove impurities, stand and age for 36 hours, and dilute to a specific gravity of 1.065 to obtain lime emulsion;

[0049] (2) Transport the lime emulsion to the carbonation reaction tower, feed carbon dioxid...

Embodiment 3

[0058] A modified calcium carbonate filled PVC pipe, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 7 parts of bismaleimide, 5 parts of acrylic acid-maleic anhydride copolymer, polyaminopropylmethyl sesqui 3 parts of siloxane, 1.5 parts of castor oil maleate, 30 parts of modified nano calcium carbonate, 4 parts of asbestos fiber, 2.5 parts of coupling agent, 1.2 parts of crosslinking agent, 0.8 parts of 1010 antioxidant, calcium zinc stabilizer 1.2 parts, 1 part of antibacterial agent and 5 parts of processing aid.

[0059] The preparation of described modified calcium carbonate comprises the steps:

[0060] (1) Put quicklime and 60°C hot water into the digestion reactor according to the mass ratio of 1:6 to carry out digestion reaction, remove impurities, stand and age for 30 hours, and dilute to a specific gravity of 1.070 to obtain lime emulsion;

[0061] (2) Transport the lime emulsion to the carbonation reaction tower, feed carbon diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com