Antibacterial pullulan/chitosan composite food packaging film and preparation method thereof

The technology of pullulan polysaccharide and polyaldehyde pullulan polysaccharide is applied in the field of pullulan polysaccharide/chitosan composite food packaging film and its preparation, and can solve the problem of lack of antibacterial biological activity, easy spoilage, and food shelf life. Shortage and other problems, to achieve the effect of synergistic antibacterial biological activity, excellent light blocking performance, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

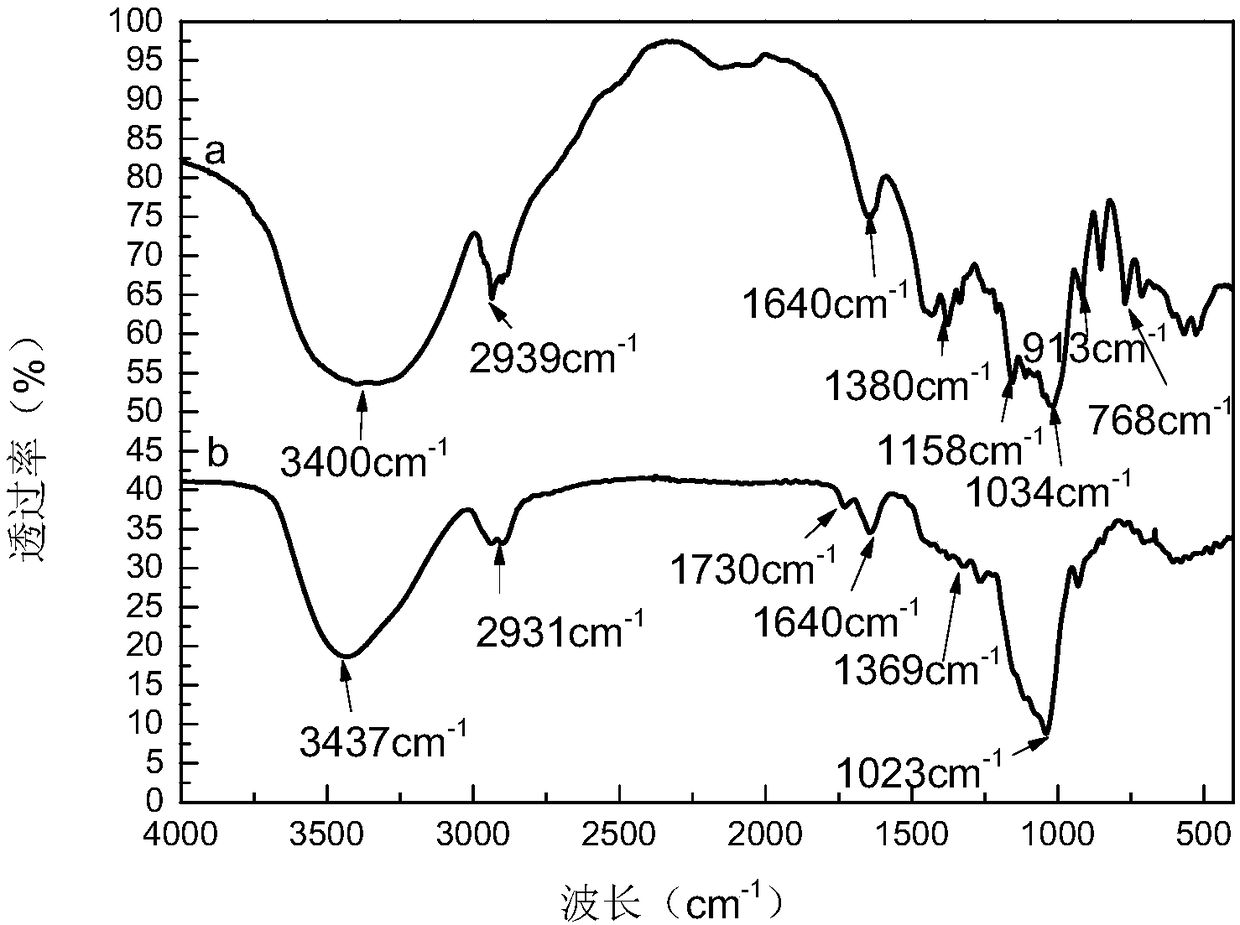

Image

Examples

specific Embodiment approach 1

[0028]Specific embodiment one: This embodiment is an antibacterial pullulan / chitosan composite food packaging film, which uses pullulan as a raw material, first utilizes sodium periodate to oxidize pullulan to obtain polyaldehyde Pullulan; then use adipic acid dihydrazide to reductively aminate polyaldehyde pullulan to obtain adipic acid dihydrazide aminated polyaldehyde pullulan; finally use adipic acid dihydrazide to aminate the polyaldehyde pullulan Polyaldehyde pullulan polysaccharide is mixed with natural bioactive antibacterial agent to obtain antibacterial pullulan / chitosan mixed solution, and the antibacterial pullulan / chitosan mixed solution is made into antibacterial pullulan by solution casting method Lantosan / chitosan food packaging film.

[0029] In recent years, the research on pullulan polysaccharide film material has become a new star in the field of food safety and food biochemical research, but in the research of various pullulan polysaccharide blend film mat...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molecular weight of the pullulan is 800,000-4,800,000. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: This embodiment is a preparation method of an antibacterial pullulan / chitosan composite food packaging film, which is specifically completed according to the following steps:

[0032] One, oxidation: ①, pullulan polysaccharide is dissolved in distilled water, obtains pullulan polysaccharide aqueous solution, the concentration of described pullulan polysaccharide aqueous solution is 5mmol / L~20mmol / L; Sodium iodate is dissolved in distilled water to obtain sodium periodate aqueous solution, the concentration of described sodium periodate aqueous solution is 0.33mol / L~0.66mol / L; ③, under dark conditions, pullulan aqueous solution and high The sodium iodate aqueous solution was mixed, and stirred at a speed of 600r / min to 1000r / min for 4h to 8h at room temperature and protected from light to obtain a reaction product, and the volume ratio of the pullulan aqueous solution to the sodium periodate aqueous solution was ( 3~5): 1; ④, transfer the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com